longrangehunterII

Well-Known Member

I've lately be necking down Lapua 308 Winchester brass to form 7mm-08 remington, and now seem to have a tight neck situation due to the extra brass increasing the thickness of the neck.

The 7mm-08 Federal and Winchester brass I've used in the past of a loaded round tends to measure around .3110", but the neck sized down Lapua brass of a loaded round measures .3150"-.3155". Which according to SAAMI is at the case neck dimensions of the case (.3150"), the chamber dimension is .3170" at the neck shoulder juncture and .3160" at the end of the chamber. Which in this case is rather tight for neck expansion to release the bullet upon firing. These loads with unturned brass have also not produced the same bug holes as the previous loads with the other brass leaving me to think I'll need to turn down the necks.

Wow..... I would never like to neck turn another piece of brass in my life again! Pain in the butt, sore palm as well from holding onto the case holder tightening and doing the neck turning its self.

My thoughts:

Neck up if at all possible. No need to neck turn since the brass neck will thin during the process.

If you neck down, I hope you have a factory chamber and not something cut like a match chamber or you might be doing a ton of work for very little gain. I found the best way with the end result being better is to turn the case first, then neck down. Or make it even easier on yourself and just inside neck ream the darn case.

Here's why:

The factory new parent case will have perfect parallel sides on the neck after running it over the mandrel. Which will prevent any excess brass from being removed that is not fully sized in the die at the neck shoulder juncture if you've already sized down.

If by chance the case as been already fire formed, then turning after will also produce a more concentric neck then if it wasn't fire form first.

I use at least a 6x magnifying glass to check the progress of the neck turning. If you turn a new unfired unsized parent case and turn the neck "to" the shoulder, you'll see that after sizing down the turned portion will become part of the new neck formed, and it will look uniform. vs. if you turn a neck down case, you will need to cut just to the point that the cutter puts a beveled edge on the shoulder. But here the deal, you'll notice when the cutter is 4/5 of the way down the neck it will start to remove more material with each turn then the rest of the neck or if done on a factory parent case or a fire formed case. That's because during the necking down in the sizing die the brass has moved to not only make the neck thicker but more brass moved into the neck shoulder juncture that the sizing die made... the "dreaded donut" and/or a false shoulder will appear. Which is why you'll need to neck turn all the way to the neck shoulder juncture. You'll also need to resize again after turning the neck, where the sizing button will iron out the donut to the out side of the neck. Which you'll avoid doing that twice if you neck turn the parent case first, or a neck reamer can be used to remove the donut/and or the neck thickness of the parent case in the first place if you'd like to forgo the neck turning altogether!

Either way avoid the hassle and buy properly head stamped brass and enjoy all that extra time shooting, hunting or watching TV for that matter. Me I still have 325 pieces of brass to do...... so I bought myself some nice gloves with blister armor in the palm so I can maybe actually finish this job I wish I didn't have to do!

The 7mm-08 Federal and Winchester brass I've used in the past of a loaded round tends to measure around .3110", but the neck sized down Lapua brass of a loaded round measures .3150"-.3155". Which according to SAAMI is at the case neck dimensions of the case (.3150"), the chamber dimension is .3170" at the neck shoulder juncture and .3160" at the end of the chamber. Which in this case is rather tight for neck expansion to release the bullet upon firing. These loads with unturned brass have also not produced the same bug holes as the previous loads with the other brass leaving me to think I'll need to turn down the necks.

Wow..... I would never like to neck turn another piece of brass in my life again! Pain in the butt, sore palm as well from holding onto the case holder tightening and doing the neck turning its self.

My thoughts:

Neck up if at all possible. No need to neck turn since the brass neck will thin during the process.

If you neck down, I hope you have a factory chamber and not something cut like a match chamber or you might be doing a ton of work for very little gain. I found the best way with the end result being better is to turn the case first, then neck down. Or make it even easier on yourself and just inside neck ream the darn case.

Here's why:

The factory new parent case will have perfect parallel sides on the neck after running it over the mandrel. Which will prevent any excess brass from being removed that is not fully sized in the die at the neck shoulder juncture if you've already sized down.

If by chance the case as been already fire formed, then turning after will also produce a more concentric neck then if it wasn't fire form first.

I use at least a 6x magnifying glass to check the progress of the neck turning. If you turn a new unfired unsized parent case and turn the neck "to" the shoulder, you'll see that after sizing down the turned portion will become part of the new neck formed, and it will look uniform. vs. if you turn a neck down case, you will need to cut just to the point that the cutter puts a beveled edge on the shoulder. But here the deal, you'll notice when the cutter is 4/5 of the way down the neck it will start to remove more material with each turn then the rest of the neck or if done on a factory parent case or a fire formed case. That's because during the necking down in the sizing die the brass has moved to not only make the neck thicker but more brass moved into the neck shoulder juncture that the sizing die made... the "dreaded donut" and/or a false shoulder will appear. Which is why you'll need to neck turn all the way to the neck shoulder juncture. You'll also need to resize again after turning the neck, where the sizing button will iron out the donut to the out side of the neck. Which you'll avoid doing that twice if you neck turn the parent case first, or a neck reamer can be used to remove the donut/and or the neck thickness of the parent case in the first place if you'd like to forgo the neck turning altogether!

Either way avoid the hassle and buy properly head stamped brass and enjoy all that extra time shooting, hunting or watching TV for that matter. Me I still have 325 pieces of brass to do...... so I bought myself some nice gloves with blister armor in the palm so I can maybe actually finish this job I wish I didn't have to do!

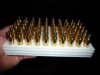

Attachments

Last edited: