I agree with all of the comments and wisdom conveyed above. Yes, I did a double take at the torch and laughed later when I learned that torch meant light and not a flame!! Glad it was so, best to ya Fordy!

Relaying a glitch I recently had while reloading in hopes that others can learn from my mistake. Many hear do single stage loading. I've used a Dillon RL550B and a Squaredeal B (handgun, .45acp) since 1990. Never had issue till couple months back. The RL550B loads many different rounds for me over the years (.308 win, 30-30, 6.8spc, .380 acp, .45 colt, .38 special, .357 magnum, 9mm). I developed a load for 6.8 SPC for hunting. Bullet is the Cavity Back Bullet copper 105g MKZ, AA2200 Powder. Previous ladder test showed node at 28.8-29.2g, loaded long at 2.295" (longer won't fit in magazine). MV ran on average at 2822fps. Relatively new to me was using AA2200 powder.

I've never had a low powder sensor on my powder hopper. Have always watched powder level when loading and when I see about an inch left in hopper, I load it up again. Loaded for 29g of powder. Loaded 150 rounds, went to the range and six misfires showed up. Extraction of the rounds showed bullets all intact, what appeared to be good strike on primer. I initially thought bad primers or bad firing pin. Couple dozen rounds had fired well, no bullets lodged in barrel, primers from a lot of 5000 I bought in 2009, fired rounds and unfired rounds, primer strike looked the same. Packed up and went home.

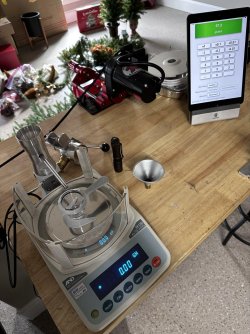

With puller, took the misfire rounds apart and sure enough, primer had fired on each, colett crimp held bullet in place. Took the remaining unfired rounds and weight separated two groups on my Ohaus scale. Greater that 240g, powder good, less than 240g, no powder. Total of 24 more rounds that indicated no powder. Pulled em all and in fact no powder. 20% defective, I called Dillon Precision and Dave explained that most times, when this issue has surfaced, it is static related and that I should use a cling free dryer sheet and wipe down every surface the powder touches. My next reload session, I plan to do so. But I'm also thinking that letting my hopper get down to what I've thought was a safe level (approx 1") maybe the culprit. At my local gun range recently, a friend that reloads described something called the angle of repose. Before he retired, he was involved in the checking of fill levels in silos and he said that all granular material has varying levels of repose. Surface tensions cause a cone shaped fill when loading a hopper and it varies from a steep cone to a shallow cone depending on the material. He thought my relatively new powder I was using may have a steep cone (higher angle of repose), as he said filling of a hopper and draining a hopper normally have the same cone shape. When filling, the cone points up. When emptying, the cone points down. I noted to him, I'd seen this when i Put fertilizer in my spreader and when it goes empty.

I think I ran my powder hopper dry and didn't see it. More frequent check as noted above, dryer wipes and fuller hopper are all in the plan from now on