There have been some great tips and precautions listed above. Go slow and maintain focus. Do one thing at a time and finish all steps on the rounds you are working up on the bench. Clearly label all of your completed rounds. If you are loading different projectiles in similar cases, be very careful to keep them separated and labeled. A 223 case with a 30 BO may fit in your 223 rifle's chamber, but will result in catastrophic damage if fired.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reloading Safety

- Thread starter Hikinghunter

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Congrats on your new endeavor! You are on to a good start. I am glad you addressed safety first because there is no substitute for safety - Murphy does not discriminate - safety, safety, safety. To be efficient in reloading does not happen overnight; I advise keeping it simple and enjoying the learning process. You have received invaluable information. Gavin did an excellent job on this video.Getting into reloading. After reading "the ABC's of reloading" by Phillip Massaro, I feel like I have a general grasp on the basics. What I'm looking for is the general "don't do this" safety measures that'll make sure I don't learn something the hard way. So far, it looks pretty simple. Anything I should add to the list below?

Note: I only plan to reload rifle ammo.

- don't mix up pistol and rifle powder (moot, as I won't be loading pistol)

- take measures to avoid spilling your primers all over the place. Keep them somewhere different from your powder.

- inspect your brass

-have a system for making sure you don't "double-load" (although it seems like if you double-loaded a rifle cartridge it would overfill and spill all over the place)

- don't smash your hand in the press

- don't light your can of powder on fire (ok, that one is a little too obvious)

Anything to add? Seems like a relatively safe endeavor if you don't do obviously dumb things. There's an endless amount of stuff to squeeze accuracy out of a round, but the basic safety measures seem pretty simple.

ADDED: Something to ponder ...

Enjoy and happy, safe reloading.

Ed

Last edited:

Doom2

Well-Known Member

There is a lot of experience here and and I will add only an observation or two to the mix. First is I would recommend that you actually write out a procedure or check list before you start the first time. It's a good place to start and check you sequence as you go through the various stages. Second, keep a log book of what you do and what you load. Sooner or later life will interrupt you in the middle of reloading and if you write down where you left off it will help you recover. It may be an hour later or a month later. Don't leave powder in your powder measure. The acetone will discolor the plastic.

A note on electronic scales. Regardless of quality, all electronic scales drift to some extent. To minimize its effect always zero/tare the scale before each measurement. Also a check weight comes in handy. It cane be as simple as a bullet that is weighed used repeatedly. A 40-55 gn bullet works well for standard cartridges and 75-100 grain for magnums is a good choice. Remember the important aspect of the scale is repeatability, not pure accuracy.

Finally, if at all possible I would recommend a mentor if you can find one. While not necessary it makes the first few sessions less stressful as you will have someone guiding you.

A note on electronic scales. Regardless of quality, all electronic scales drift to some extent. To minimize its effect always zero/tare the scale before each measurement. Also a check weight comes in handy. It cane be as simple as a bullet that is weighed used repeatedly. A 40-55 gn bullet works well for standard cartridges and 75-100 grain for magnums is a good choice. Remember the important aspect of the scale is repeatability, not pure accuracy.

Finally, if at all possible I would recommend a mentor if you can find one. While not necessary it makes the first few sessions less stressful as you will have someone guiding you.

Citified

Well-Known Member

In the continuous quest for accuracy, some time ago I started to weigh the powder charge twice. Every now and again it will be off by .1 and is easy to correct. Like others, I look into the charged cases before seating the bullets to be sure they all look about the same.

nksmfamjp

Well-Known Member

- Joined

- Jan 5, 2004

- Messages

- 3,494

A lot of great advice has been given.

Let's talk about pressure. Guns are designed in some kind of a fatigue plus pressure vessel for human use methodology. This is tricky because if both methods are directly combined, the factor of safety becomes so high that you could not carry the guns around. There is also a historical perspective in firearms design where guns were made before much of the engineering science was less complete than today.

All I am saying is a single overload of moderate pressure increase is not going to blow your gun up, but it still may be too hot.

Gun blow ups are often related to multiple factors between unsuitable ammo, too clean or too dirty bore, mechanical issues with the gun, etc. I guess I'm saying if you run a 75000 psi load down your bore of a bolt gun, that alone won't damage your gun. That with a crack case head or clogged bore could damage your gun.

When you reload, be very careful to inspect for case condition, a crack in the case creates a high pressure jet of gas like a cutting torch. Bad for the gun and bad for the shooter.

Always match primers to the case type and load data.

Powder selection is a bit trickier. Powder selection is basically set by burn rate, but trying to guess a powder often puts you outside manual recommendations….why? Manuals select powders based on burn rate, pressure development characteristics, and stability. All 3 are super important and you cannot see stability very clearly without shooting.

A manual will never put you in too bad of a powder.

So, learn pressure signs, shoot ladders from min to max in the manual. Find that pressure sign and back off about 1-2%.

One benefit of working in this area of the load spectrum is high pressure safe loads can be very accurate and very stable. Notice I say high pressure, not over max pressure.

So how do I manage this…

Plan your load. Study all the data you have for what powders are available, what you may have, what provides velocity you want, what is temp stable, etc.

Load your plan. Take notes on each step including target measurements and samples of actual. Setup your process and throw some test charges before making your keepers. Have one powder on the bench, as many have said. Label what's in the measure. Write down your target charge weight and range…..no, you don't have to do all this….you have to develop a system that works and allows you to stay on task. Make sure your scale is truly capable. Mechanical scales get dirty/dusty which greatly affects their reliability.

Check your load. Look for velocity at or below book value when adjusted for barrel length. Look for pressure signs. Look for large group accuracy. Look for good <20 sd.

Let's talk about pressure. Guns are designed in some kind of a fatigue plus pressure vessel for human use methodology. This is tricky because if both methods are directly combined, the factor of safety becomes so high that you could not carry the guns around. There is also a historical perspective in firearms design where guns were made before much of the engineering science was less complete than today.

All I am saying is a single overload of moderate pressure increase is not going to blow your gun up, but it still may be too hot.

Gun blow ups are often related to multiple factors between unsuitable ammo, too clean or too dirty bore, mechanical issues with the gun, etc. I guess I'm saying if you run a 75000 psi load down your bore of a bolt gun, that alone won't damage your gun. That with a crack case head or clogged bore could damage your gun.

When you reload, be very careful to inspect for case condition, a crack in the case creates a high pressure jet of gas like a cutting torch. Bad for the gun and bad for the shooter.

Always match primers to the case type and load data.

Powder selection is a bit trickier. Powder selection is basically set by burn rate, but trying to guess a powder often puts you outside manual recommendations….why? Manuals select powders based on burn rate, pressure development characteristics, and stability. All 3 are super important and you cannot see stability very clearly without shooting.

A manual will never put you in too bad of a powder.

So, learn pressure signs, shoot ladders from min to max in the manual. Find that pressure sign and back off about 1-2%.

One benefit of working in this area of the load spectrum is high pressure safe loads can be very accurate and very stable. Notice I say high pressure, not over max pressure.

So how do I manage this…

Plan your load. Study all the data you have for what powders are available, what you may have, what provides velocity you want, what is temp stable, etc.

Load your plan. Take notes on each step including target measurements and samples of actual. Setup your process and throw some test charges before making your keepers. Have one powder on the bench, as many have said. Label what's in the measure. Write down your target charge weight and range…..no, you don't have to do all this….you have to develop a system that works and allows you to stay on task. Make sure your scale is truly capable. Mechanical scales get dirty/dusty which greatly affects their reliability.

Check your load. Look for velocity at or below book value when adjusted for barrel length. Look for pressure signs. Look for large group accuracy. Look for good <20 sd.

Good point, but I would clarify….you need to know exactly what powder is in the manual, transferred to your plan and loaded into your process. There are really no acceptable errors in powder selection for loading, even if you and the gun survive.- don't mix up pistol and rifle powder (moot, as I won't be loading pistol)

Good point.-have a system for making sure you don't "double-load" (although it seems like if you double-loaded a rifle cartridge it would overfill and spill all over the place)

Calipers help you control oal. OAL impacts start pressures, which can impact max pressures and the pressure duration.Why would calipers be a safety thing? I do have a good one, just wondering.

All good information above. I would add… after selecting a powder charge you want to adjust your seating depth to tune your load to your rifle. Seat a series of loads to the longest seating depth you would ever use. Take your press and seating die to the range. Figure out a remote way to clamp it to the bench beside you. Seat three and shoot three. 0.003" increments make all the difference. You will find a seating depth that consistently results in the best groups. By doing this at the range you don't waste any and you can repeat the same depth to double check your results. Number your targets so you can correlate them to the seating depth used. Cut out your targets and tape them in your log book, noting the seating depth of each target.

SteveBurton

Formerly 'Jackmonkey'

There is lots of good info in this post and you can find a ton more if you search these forums. I will add this...

-Only have one powder on the bench when you are reloading for a particular cartridge and double check that it is correct.

When I first started out, I had all my powder lined up at the back of my bench. I was loading for my 270WSM and instead of grabbing the H4350, I grabbed the H4198. I was just looking for the color of the label and they were very similar 25 years ago. Loaded some ammo and went to the range. My Winchester M70 exploded on the first shot. Split the front of the receiver, blew the barrel off, shattered the stock and broke the Leupold scope in half. God was looking over me that day because the only injury I sustained was a fiberglass splinter in my hand. Since then, I double and triple check every component that goes on my bench when reloading to verify it is correct. I may be slower than others but it's worth it to me.

-Only have one powder on the bench when you are reloading for a particular cartridge and double check that it is correct.

When I first started out, I had all my powder lined up at the back of my bench. I was loading for my 270WSM and instead of grabbing the H4350, I grabbed the H4198. I was just looking for the color of the label and they were very similar 25 years ago. Loaded some ammo and went to the range. My Winchester M70 exploded on the first shot. Split the front of the receiver, blew the barrel off, shattered the stock and broke the Leupold scope in half. God was looking over me that day because the only injury I sustained was a fiberglass splinter in my hand. Since then, I double and triple check every component that goes on my bench when reloading to verify it is correct. I may be slower than others but it's worth it to me.

fta0303

Well-Known Member

I apologize for the long windedness. I've tried to distill what I've learned in a lifetime of reloading, so it's bit lengthy. I haven't included anything that isn't in my view of some importance. I'd say good luck, but if you do it properly, there shouldn't be any room for luck. Do have some enjoyment out of it, and be proud that you can make high quality ammo.

CONSCIOUSLY DESIGN YOUR RELOADING PROCESS. This should include where each tool and component sits on your bench, to facilitate a safe process and an efficient one. Write down your process in your log, including each loading step and each inspection step. Criticize it for safety. If you've done this properly, you'll have high confidence that you will load safe ammunition. In performing your process, you should not find yourelf fumbling for something or confused about what you are doing. Map it out as though you are going to teach it to a small child.

TIPS:

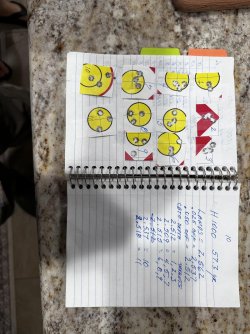

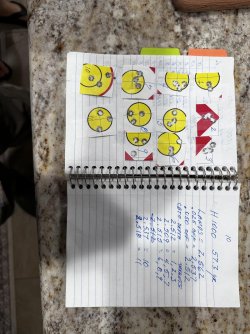

Get a bound notebook and use it to log your reloading: date, bullets, brass, primers, case and cartridge measurements, comment and observations, the process you follow, and range records.

Keep your bench neat and orderly.

Wear safety glasses when priming.

Only 1 can of powder and 1 box of primers and one box of bullets on the bench.

Never force anything - if it sticks, stop and find out what's going on.

Don't be in a hurry - learn to enjoy executing each step in your process.

Don't admit distractions to your reloading area: no radio, no TV, no telephone, no other people. If interrupted, as you inevitably will be, deliberately recover your place in the process efore resuming.

Use loading blocks and perform one process step at a time* on all your cases.

Get some plastic boxes for your loaded ammo and label them with the powder and amount, primer, bullet, date. This info will tie back to your reloading log.

Avoid using fluorescent lighting; it can set up a variable magnetic field that precludes your balance from settling to a stable reading.

Pick a load having a power charge large enough to spill our of the case if you double-charge it. (May not be able to do this with a pistol cartridge).

THE CHARGING STEP IS WHERE DANGEROUS MISTAKES CAN OCCUR, BY OVERCHARGING OR UNDERCHARGING. I do it as follows:

Set up with a loading block left of your scale, for empty cases, and a loading block right of your scale for charged cases. Remove a case from the left charging block. Turn it upside down and tap it on the bench. Place it at left front of scale. Weigh your charge, LOOK INTO YOUR EMPTY CASE TO CONFIRM IT'S EMPTY, then load your charge into it. Transfer the charged case to the right loading block. Don't try to load more cartridges than your loading block will hold.

Use a flashlight and a magnifying glass to inspect the charge in each case in your loading block when it's full. I do it once by row, once by column. Be deliberate. You can then seat your bullets. It wouldn't be stupid to visually inspect each charged case before placing the bullet in it, to insure that there is a full charge in the case. UNDERLOADING OR MISSING A CHARGE CAN LEAD TO A DISASTER AT THE RANGE, may be as dangerous as double charging.

I weigh out my charge to slightly below desired weight on a balance, transfer it to my electronic scale and use a small pharmacist's spoon to trickle the charge to desired amount. I always zero both balance and scale using known reference weights prior to starting, then don't move either. I don't use a powder measure, as they typically are only marginally accurate. It's my thought that the extra time put into assuring an as accurate as possible charge weight is well worth it. Each piece of ammo that you produce is an example of your craftsmanship - do it justice. At the range, you are practising to achieve something, not just spraying bullets. Each shot should be a shot that counts: you really don't need a high volume production.

I'm 72, have been reloading since I was ten. I'm a safer reloader today than I was when i started, than I was 20 years ago. I'm not an expert, but I'm not afraid to shoot the ammo I've loaded. Reloading is potentially dangerous, but people work with dangerous materials and processes all the time by designing safe processes.

*I used to load one cartridge at a time. I found it was easy to miss charging a case. If you use blocks and charge 20 to 50 at a time, you can consciously include a separate inspection step, rather than trying to inspect each cartridge as you go.

CONSCIOUSLY DESIGN YOUR RELOADING PROCESS. This should include where each tool and component sits on your bench, to facilitate a safe process and an efficient one. Write down your process in your log, including each loading step and each inspection step. Criticize it for safety. If you've done this properly, you'll have high confidence that you will load safe ammunition. In performing your process, you should not find yourelf fumbling for something or confused about what you are doing. Map it out as though you are going to teach it to a small child.

TIPS:

Get a bound notebook and use it to log your reloading: date, bullets, brass, primers, case and cartridge measurements, comment and observations, the process you follow, and range records.

Keep your bench neat and orderly.

Wear safety glasses when priming.

Only 1 can of powder and 1 box of primers and one box of bullets on the bench.

Never force anything - if it sticks, stop and find out what's going on.

Don't be in a hurry - learn to enjoy executing each step in your process.

Don't admit distractions to your reloading area: no radio, no TV, no telephone, no other people. If interrupted, as you inevitably will be, deliberately recover your place in the process efore resuming.

Use loading blocks and perform one process step at a time* on all your cases.

Get some plastic boxes for your loaded ammo and label them with the powder and amount, primer, bullet, date. This info will tie back to your reloading log.

Avoid using fluorescent lighting; it can set up a variable magnetic field that precludes your balance from settling to a stable reading.

Pick a load having a power charge large enough to spill our of the case if you double-charge it. (May not be able to do this with a pistol cartridge).

THE CHARGING STEP IS WHERE DANGEROUS MISTAKES CAN OCCUR, BY OVERCHARGING OR UNDERCHARGING. I do it as follows:

Set up with a loading block left of your scale, for empty cases, and a loading block right of your scale for charged cases. Remove a case from the left charging block. Turn it upside down and tap it on the bench. Place it at left front of scale. Weigh your charge, LOOK INTO YOUR EMPTY CASE TO CONFIRM IT'S EMPTY, then load your charge into it. Transfer the charged case to the right loading block. Don't try to load more cartridges than your loading block will hold.

Use a flashlight and a magnifying glass to inspect the charge in each case in your loading block when it's full. I do it once by row, once by column. Be deliberate. You can then seat your bullets. It wouldn't be stupid to visually inspect each charged case before placing the bullet in it, to insure that there is a full charge in the case. UNDERLOADING OR MISSING A CHARGE CAN LEAD TO A DISASTER AT THE RANGE, may be as dangerous as double charging.

I weigh out my charge to slightly below desired weight on a balance, transfer it to my electronic scale and use a small pharmacist's spoon to trickle the charge to desired amount. I always zero both balance and scale using known reference weights prior to starting, then don't move either. I don't use a powder measure, as they typically are only marginally accurate. It's my thought that the extra time put into assuring an as accurate as possible charge weight is well worth it. Each piece of ammo that you produce is an example of your craftsmanship - do it justice. At the range, you are practising to achieve something, not just spraying bullets. Each shot should be a shot that counts: you really don't need a high volume production.

I'm 72, have been reloading since I was ten. I'm a safer reloader today than I was when i started, than I was 20 years ago. I'm not an expert, but I'm not afraid to shoot the ammo I've loaded. Reloading is potentially dangerous, but people work with dangerous materials and processes all the time by designing safe processes.

*I used to load one cartridge at a time. I found it was easy to miss charging a case. If you use blocks and charge 20 to 50 at a time, you can consciously include a separate inspection step, rather than trying to inspect each cartridge as you go.

Lots of good advice here. I'll add that I found it best/safest to only do one step at a time. Some people might seat bullets while powder is dispensing in another casing. I like to do one step on all rounds to stay focused on one particular task. And I recommend using loading blocks to hold your cartridges. So I use two loading blocks, place all my cartridges in one block and have one block empty. Dispense powder in one case, move it to the new block. When done all are moved to the second block. I concentrate on the task at hand (measured powder dispensing), do all cartridges then move to the next step (bullet seating). I personally find this to be a more careful and focused approach.

Something to keep in mind, everyone's rifle is different. Just because some guy can stuff x amount of grains into a cartridge doesn't necessarily mean you can. I have seen a lot of questionable loads on the internet. Be cautious. Any cartridge in particular you are going to reload?

Jim’s Hunt

Well-Known Member

Looks as though guys have covered about all safety items. I like a clean orderly non cluttered bench. I keep the powder container that I'm using on the bench until I'm done and emptied the hopper back into container it came from. I also stick the bullet point down in the case after I put the powder in. I double weigh my powder. I use an auto thrower (Lyman Gen 5) then check it on an Ohaus 10/10 balance beam.

the big greasy

Well-Known Member

Get a couple different load manuals and see what they are calling for. Don't just go by one. And start low. One load manual for 2 of my rifles now I was at max pressure and I was in middle of load data.