Cartridge makes difference, Mitch at 2 miles was correcting 110-120 min, elevation, where the closest competitor was over 150 min.

Hello,

Elevation in its' simplest form as you referring to is the easiest controlled variable in the entire formula though. It is easily controlled, accounted for and offset mechanically. MV speed is useless without consistentcy. And there are lots that affect that consistentcy.

Where elevation gets swirly and complicated is the external factors that affect it such as internal pressure deviations due to case design, internal pressure deviations due to ammunition temperature, internal pressure deviations due to chamber temperature, internal pressure deviations due to powder location in the case, yada yada yada.

It is NOT as simple as running a cartridge from your brass, its just NOT.

So lets discuss some of these external factors

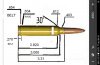

1. Case design affecting internal pressure deviations which affects MV deviations, which affects POI being different than the accounted for elevation requirements. Several design features account for this, such as web thickness, primer pocket, body taper, neck angle. The original CT brass had this design problem in regards to web thickness being too thin. MV deviations were close to 75fps due to that. The BMG primed CT cases had close to 100fps MV deviations due to case being weakened to fit the larger primer.

2. Ammunition temperatures affecting internal pressure deviations which affects MV deviations, which affects POI being different that the accounted for elevation requirements. A 15 degree external brass temperature on the 375CT gives about a 25fps MV deviation and we already know that just a 5fps MV deviation puts us under/over the KO2M target size.

3. Powder location affecting internal pressure deviations which affects MV deviations, which affects POI being different that the accounted for elevation requirements. Do you store your ammunition with projectile up or down before loading into chamber and are you consistent no matter which direction you take.

And this is just the tip of the iceberg in regards to external variables affecting an internal ballistic formula, that in turn affects the external ballistic solution. There is NO cartridge case design that is going to be more valuable and make more of a difference than the shooter/spotters themselves.

THEIS