Justice1327

Well-Known Member

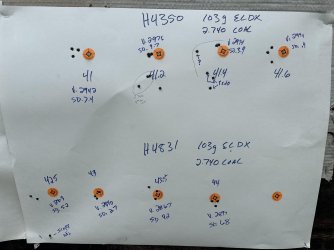

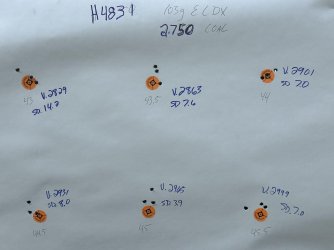

Gonna try a powder change to H4831 then do a primer change… but I've never had a primer change my grouping that muchAt some point you gotta cut losses. It's not worth the headache or components. Even if you did find a load that would work for this barrel it would probably be finicky as heck. I think I'd pull the barrel and move on.

I went through this with a barrel. I was much happier when I just pulled it and put on a new one.

Last edited: