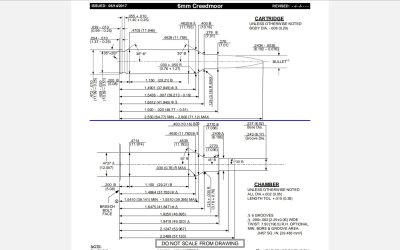

I purchased a Seekins Havak PH2-NRL in 6 Creedmoor and recently finished firing my first 100 rounds through virgin Petersen brass. Sizing the 1x fired brass was difficult, so I took some measurements of the sized vs fired brass.

The outside neck diameter of the sized brass is .266. The outside diameter of the fired brass is .278, for a .012 difference.

The diameter of the brass body just before the shoulder is .462 on sized brass and .467 on fired brass for a .005 difference.

The FL die is from Short Action Customs and was used to neck size the virgin brass prior to initial firing. All measurements I've taken of the sized brass appear to be in spec with where they should be.

I am trying to determine if the chambering may be too large in the action. I suppose I could measure some sized vs fired brass in other cartridges to compare the variances, but I was curious if anyone knew what the bore chamber specifications should be compared to the brass. Hopefully this question makes sense!

The outside neck diameter of the sized brass is .266. The outside diameter of the fired brass is .278, for a .012 difference.

The diameter of the brass body just before the shoulder is .462 on sized brass and .467 on fired brass for a .005 difference.

The FL die is from Short Action Customs and was used to neck size the virgin brass prior to initial firing. All measurements I've taken of the sized brass appear to be in spec with where they should be.

I am trying to determine if the chambering may be too large in the action. I suppose I could measure some sized vs fired brass in other cartridges to compare the variances, but I was curious if anyone knew what the bore chamber specifications should be compared to the brass. Hopefully this question makes sense!