Update and questions on the 250 Savage build. I now plan to build two rifles.

First up will be a basic hunting rifle for my grandson capable of taking whitetails and hogs out to 200 yards. I picked the 250 Savage based on nostalgia, and very mild recoil and report relative to performance. I went with the Axis action due to cost versus the 110. For this gun I have in hand a Shaw barrel with a 10 twist in sporter profile, and a new Axis youth model with a 7mm-08 barrel that we'll keep for future steps up the performance ladder.

Second gun will be a heavier bench/hunting gun for me and the boys to play with and learn with. I have in hand a 26" Shilen barrel with a 10 twist in a heavy varmint profile. I also have a new Axis II with wood stock in .243 Win. This is a really nice little rifle right now, and it's gonna hurt to take it apart, but I can put it all back together if I want.

First observation/potential problem: The chambers on the two barrels are obviously different, and I'm having concerns about head space on the Shaw barrel. With the two barrels laying on my bench and a box of factory 100g Hornady in hand, I decided to just see how the ammo felt in each chamber.

With the Shilen barrel a new round slips in smoothly and bottoms out with a nice snug fit, and there is .138 of brass sticking out. I can barely feel a tiny amount of movement when I wiggle the base. The round slips out just as smoothly with zero resistance.

With the Shaw barrel a new round slips in smoothly, but doesn't fit as snugly. I can feel slightly more movement when I wiggle the base of the round. When I first measured, I got .137 of brass sticking out, but I can push the brass in to about .134 with my thumb. When I pull it out, it has some initial resistance as if the bullet is slightly stuck, especially if I've pushed it in harder with my thumb.

When I installed the Shaw barrel on the action, I first set the headspace with a new go-gauge and used one layer of tape to check no-go. When I chambered a new round, there was some resistance on closing the bolt. I had the ejector and extractor removed from the bolt, and the round stayed in the barrel. I had to use a cleaning rod with a slight bump to remove it. I installed the extractor and used a marker on the bullet and neck, then I cycled the round. It extracted but with a bit of force needed to lift the bolt. I found a clean ring all the way around the bullet a few thousandths above the neck. I wasn't sure if the bullet was touching the entry to the free bore, or the leading edge of the lands. I was able to reset the headspace with one layer of tape for the go setting, and two layers for the no-go. This resolved the issue and a new round chambers and extracts smoothly.

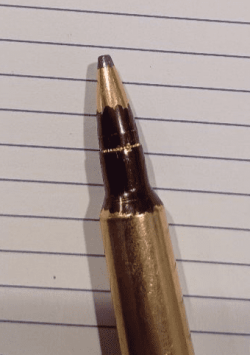

This morning with the barrel removed I marked up another bullet and chambered it with thumb pressure. In the attached photo you can hopefully see the faint contact ring around the bullet ogive.

I decided to see if this group has thoughts on what's going on and if I need to make changes before finishing this rifle.? Do I set it up with one layer of tape for the go and two layers for no-go?

Also, I'm thinking interchangeability of reloaded ammo between these two rifles may be a problem.?