I was asking Taylorbok's set-up.30 inch barrel and 107grn capacity

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Curious question

- Thread starter darrindlh

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

32" tube. IIRC it's 100gr of H2O but i'd have to check my note bookWhat's the barrel length and case capacity?

darrindlh

Well-Known Member

i hope they have significantly tightened up their actual time to completion and shipping, for You.

The results of this case modification ought to be impressive!

The results of this case modification ought to be impressive!

darrindlh

Well-Known Member

I hope so. I truly am learning alot. This is my first time journeying down this path of case modification. Im nervous but know what I want to achieve.i hope they have significantly tightened up their actual time to completion and shipping, for You.

The results of this case modification ought to be impressive!

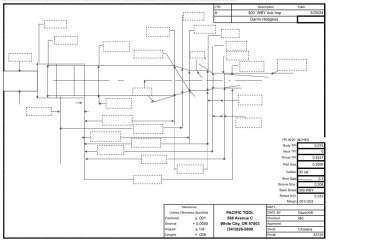

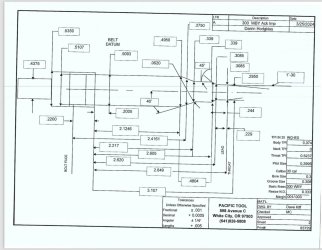

I'm not sure why they would send you an incomplete reamer print form. That's a red flag.Here is the chamber sketch . Nothing special but just waiting on my reamer. Its ordered, 6-8 weeks out!

Darrin

I'd avoid PTG, maybe they've changed but from my personal experience and all the horror stories you hear it's surprising they are still in business.

JGS or Manson should be able to help you out with a reamer if this fails.

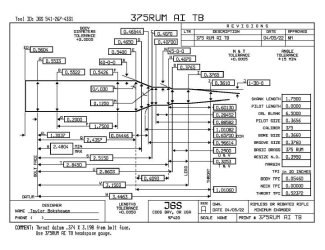

FWIW this is what a reamer print should look like

Attachments

darrindlh

Well-Known Member

I called JGS, they told me they could not help me. I was a little shocked cause I need a custom reamer made. But the were hell bent because my parent case was a Weatherby case . I'll call PTG againI'm not sure why they would send you an incomplete reamer print form. That's a red flag.

I'd avoid PTG, maybe they've changed but from my personal experience and all the horror stories you hear it's surprising they are still in business.

JGS or Manson should be able to help you out with a reamer if this fails.

FWIW this is what a reamer print should look like

darrindlh

Well-Known Member

Taylor just called PTG they were confused The print I had had no values. They are re sending the print now. I'll post itI'm not sure why they would send you an incomplete reamer print form. That's a red flag.

I'd avoid PTG, maybe they've changed but from my personal experience and all the horror stories you hear it's surprising they are still in business.

JGS or Manson should be able to help you out with a reamer if this fails.

FWIW this is what a reamer print should look like

darrindlh

Well-Known Member

darrindlh

Well-Known Member

Can someone help me understand the difference with a chamber reamer print and cartridge print. The reason is, I'm looking at the reamer print and I was hoping to see more straightening f the case taper . But I'm not sure what I'm seeing . I'm just really trying to learn. Sorry for all the questions

Darrin

Darrin

Last edited:

From what I can see you've got .018" per inch of body taper. Usually .010" is the recommended minimum for bottleneck cartridges, that drawing I posted above has .0055" tpi and it's working well.Can someone help me understand the difference with a chamber reamer print and cartridge print. The reason is, I'm looking at the reamer print and I was hoping to see more straightening f the case taper . But I'm not sure what I'm seeing . I'm just really trying to learn. Sorry for all the questions

Darrin

darrindlh

Well-Known Member

So this is to much taper then is what your saying. It will not blow out the case as much. My Tpi is .074.From what I can see you've got .018" per inch of body taper. Usually .010" is the recommended minimum for bottleneck cartridges, that drawing I posted above has .0055" tpi and it's working well.

Last edited:

MagnumManiac

Well-Known Member

I designed my wildcats on the 416 Rigby case to have .005" per inch taper, which is absolute minimum for a bottlenecked case, but using steep shoulder angle and 20% over calibre for neck length, it is doable.

This is why I wondered what you meant when you originally said increasing shoulder angle without any other dimension listed. You should gain 5-8g powder without decreasing case taper as is now, but you could gain more removing case taper to .010" per inch.

Cheers.

This is why I wondered what you meant when you originally said increasing shoulder angle without any other dimension listed. You should gain 5-8g powder without decreasing case taper as is now, but you could gain more removing case taper to .010" per inch.

Cheers.

I saw that on the print but I can't make sense of it. The case never had that much taper, it says TPI over 20" but that doesn't add up either. I came up with .018 after comparing 2 datums and reducing by their distance apart. To maximize volume I'd ask them to give it .010 case taperSo this is to much taper then is what your saying. It will not blow out the case as much. My Tpi is .074.