-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ChargeMaster scale inconsistent

- Thread starter DanMan

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Do you measure the inside diameter of the chargemaster drop tube to find the correct tube to buy. Calipers work?FORGET THE GOOFY STRAW and buy these. My Chargemaster throws my charges spot on every time.

BiggBeans

Well-Known Member

Just buy one of these and be done with that ****

Rockbottom

Active Member

For the two cartridges I load often, I use a B&M but a different electronic check scale. I can leave my two B&M tubes set for those two cartridges. I have two Redding throwers for stuff I don't load often or when I want to try different components. I never went down the automatic charge rabbit hole.Temperature, static, electronic interference, whether or not your let it "warm up", day of the week, whether your dog was nearby or not -- so many things seem to affect these. If you're in the path of the air register blowing air on it, add that to the list.

My RCBS (gen 1) grew more inconsistent with time. On mine, you could program the weight below final setting where it would slow to trickle. Made a world of difference on long stick powders. Still, it kept becoming more inconsistent. Gave it away.

I replaced it with a Hornady LnL You could customize the dispense settings on the Hornady too, but it would lose them and return to default when you powered it off. It wasn't much better.What I absolutely *hated* about the Hornady is if it threw over, it would beep, then within a second, switch the display to the target weight. Problem was, sometimes the beep meant .3gr over, sometimes 1gr over.

I got sick of it and sold it.

Now I throw manually with an antique Belding & Mull powder drop and check it with a US Solid electronic check scale -- exact every time and with bottleneck cases, easily 2-3x faster.

Last edited:

That's the ****.

Mikecr

Well-Known Member

I believe the people developing this for RCBS pulled a slick one there.even though it stops and beeps at the programmed 68.0 grains, after flashing the round count the weight returns at something like 68.2 or so.

Somewhere in the programming there must be a routine to set the charge display equal to desired, when the program decides that the charge is close enough to stop jogging (the charge is dispensed). This making it seem like dispensing is always right on the money.

But when you disturb the pan, or otherwise allow it to read in simple scale mode, you see that an extra kernel or two might have fallen & put the charge over desired.

It would have been better for us if the scale reading always stayed real, so that at the end of dispensing we would see how much error we might have. Then we could adjust the program settings for better if needed, with that particular powder.

That less than ethical move of theirs messed us up, and it messed them up as well.

How could they assume that reloaders are so dumb, that we would not check and see this going on?

Now the CM is famously inaccurate, and everyone is modifying their units, opening the door for competition.

I'm good with my RCBS CM, as I've modified.

But I'm watching them fail to fix their product. Still sure that we are dumb..

Rum River

Well-Known Member

- Joined

- Mar 31, 2009

- Messages

- 172

For years I've been using the RCBS powder metering system where the Powder Pro scale and the metering are two separate units. It still works so I'm happy.

A couple weeks back I screwed up and got the two power supplys mixed up. Didn't damage anything but was getting an 'Err1' message when calibrating the scale. Until then I didn't know there was a way to do a 'factory calibration'. Once I went through all those steps everything works again - and now I make sure I keep the power supply correct!

I plug my scale in for at least 15-20 minutes to warm up, watch out for drafts, etc.

***One other thing to remember is that the LCD readout on the scale takes time to respond. On my system the motor will stop dispensing powder but the scale still reads light - I have to wait maybe 3 seconds for the scale to catch up.***

If you're taking the pan off an LCD-readout scale immediately after the motor stops there's a chance you don't have the powder charge you think you have.

For those interested, below are the steps to do the factory calibration.

I know lots of shooters on this forum have much newer equipment, but you never know.

Tedious steps, but I can say it worked out perfect for me.

*************************************************************************************

If you have the Powder Pro Powder Scale:

1. Remove the Scale Pan from the Platen

2. The scale must be turned off. (If the "On/Off" button does not work, unplug the scale and depress each of the four buttons five times. Plug the scale back in and proceed.

3. Press the "On/Off" button to turn the scale on. The display will read "test" for about 1 or 2 seconds.

4. While the word "test" is showing on the display, you must simultaneously press and hold for 5 seconds the "Gms/Grains", the "Zero" and the "On/Off" buttons. Do not press the "Cal" button. The display will now read "- -0-". Id the display reads "00.0", either you were not fast enough, or the buttons did not go down simultaneously. Turn the scale off and try again beginning with #3 above.

5. When you get the "- -0-" press the "Cal" button, the display will read "hold" and then"- -20-". Place the 20 weight on platen. Wait about 5 seconds to allow the scale to stabilize, then press "Cal", "hold" will appear and then "- -50-". Place the 50 weight on the platen. Wait for about 5 seconds to allow the scale to stabilize and press hold. The scale will ask for the "- -70-" weight. Place the small weight on top of the large one. Wait for about 5 seconds to allow the scale to stabilize. Press "Cal", the scale will read "hold" then "- -0-". Place the weights back in the storage wells and press "Cal". The display will now read "hold" followed by "00.0". To be absolutely safe, the scale should now be calibrated following the Calibration procedure found in the instruction booklet.

If you have the Partner Powder Scale:

1. Remove the Scale Pan from the Platen.

2. The scale must be turned off. (If the "On/Off" button does not work, disconnect the battery and depress each of the four buttons five times. Re-attach the battery and proceed.

3. Press the "On/Off" button to turn the scale on. The display will read "test" for about 1 or 2 seconds.

4. While the word "test" is showing on the display, you must simultaneously press and hold for 5 seconds the "Gms/Grains", the "Zero" and the "On/Off" buttons. Do not press the "Cal" button. The display will now read "- -0-". If the display reads "00.0", either you were not fast enough, or the buttons did not go down simultaneously. Turn the scale off and try again beginning with #3 above.

5. When you get the "- -0-" press the "Cal" button, the display will read "hold" and then"- -20-". Place the 20 weight on platen. Wait about 5 seconds to allow the scale to stabilize, then press "Cal", "hold" will appear and then "- -30-". Place the 30 weight on the platen. Wait for about 5 seconds to allow the scale to stabilize and press hold. The scale will ask for the "- -50-" weight. Place the small weight on top of the large one. Wait for about 5 seconds to allow the scale to stabilize. Press "Cal", the scale will read "hold" then "- -0-". Place the weights back in the storage wells and press "Cal". The display will now read "hold" followed by "00.0". To be absolutely safe, the scale should now be calibrated following the Calibration procedure found in the instruction booklet.

NOTE: The display may build "8's and 0's" after you release the three buttons in step 4. Press "cal" to get out of this. It will then give you an arbitrary number. Ignore this by pressing "cal" again. Then you will get the --0- reading. Continue with the calibration.

A couple weeks back I screwed up and got the two power supplys mixed up. Didn't damage anything but was getting an 'Err1' message when calibrating the scale. Until then I didn't know there was a way to do a 'factory calibration'. Once I went through all those steps everything works again - and now I make sure I keep the power supply correct!

I plug my scale in for at least 15-20 minutes to warm up, watch out for drafts, etc.

***One other thing to remember is that the LCD readout on the scale takes time to respond. On my system the motor will stop dispensing powder but the scale still reads light - I have to wait maybe 3 seconds for the scale to catch up.***

If you're taking the pan off an LCD-readout scale immediately after the motor stops there's a chance you don't have the powder charge you think you have.

For those interested, below are the steps to do the factory calibration.

I know lots of shooters on this forum have much newer equipment, but you never know.

Tedious steps, but I can say it worked out perfect for me.

*************************************************************************************

If you have the Powder Pro Powder Scale:

1. Remove the Scale Pan from the Platen

2. The scale must be turned off. (If the "On/Off" button does not work, unplug the scale and depress each of the four buttons five times. Plug the scale back in and proceed.

3. Press the "On/Off" button to turn the scale on. The display will read "test" for about 1 or 2 seconds.

4. While the word "test" is showing on the display, you must simultaneously press and hold for 5 seconds the "Gms/Grains", the "Zero" and the "On/Off" buttons. Do not press the "Cal" button. The display will now read "- -0-". Id the display reads "00.0", either you were not fast enough, or the buttons did not go down simultaneously. Turn the scale off and try again beginning with #3 above.

5. When you get the "- -0-" press the "Cal" button, the display will read "hold" and then"- -20-". Place the 20 weight on platen. Wait about 5 seconds to allow the scale to stabilize, then press "Cal", "hold" will appear and then "- -50-". Place the 50 weight on the platen. Wait for about 5 seconds to allow the scale to stabilize and press hold. The scale will ask for the "- -70-" weight. Place the small weight on top of the large one. Wait for about 5 seconds to allow the scale to stabilize. Press "Cal", the scale will read "hold" then "- -0-". Place the weights back in the storage wells and press "Cal". The display will now read "hold" followed by "00.0". To be absolutely safe, the scale should now be calibrated following the Calibration procedure found in the instruction booklet.

If you have the Partner Powder Scale:

1. Remove the Scale Pan from the Platen.

2. The scale must be turned off. (If the "On/Off" button does not work, disconnect the battery and depress each of the four buttons five times. Re-attach the battery and proceed.

3. Press the "On/Off" button to turn the scale on. The display will read "test" for about 1 or 2 seconds.

4. While the word "test" is showing on the display, you must simultaneously press and hold for 5 seconds the "Gms/Grains", the "Zero" and the "On/Off" buttons. Do not press the "Cal" button. The display will now read "- -0-". If the display reads "00.0", either you were not fast enough, or the buttons did not go down simultaneously. Turn the scale off and try again beginning with #3 above.

5. When you get the "- -0-" press the "Cal" button, the display will read "hold" and then"- -20-". Place the 20 weight on platen. Wait about 5 seconds to allow the scale to stabilize, then press "Cal", "hold" will appear and then "- -30-". Place the 30 weight on the platen. Wait for about 5 seconds to allow the scale to stabilize and press hold. The scale will ask for the "- -50-" weight. Place the small weight on top of the large one. Wait for about 5 seconds to allow the scale to stabilize. Press "Cal", the scale will read "hold" then "- -0-". Place the weights back in the storage wells and press "Cal". The display will now read "hold" followed by "00.0". To be absolutely safe, the scale should now be calibrated following the Calibration procedure found in the instruction booklet.

NOTE: The display may build "8's and 0's" after you release the three buttons in step 4. Press "cal" to get out of this. It will then give you an arbitrary number. Ignore this by pressing "cal" again. Then you will get the --0- reading. Continue with the calibration.

I don't use an automatic powder dispenser simply because while they do help with volume reloading their accuracy leaves something to be desired. It's not the fault of the powder dispenser it has more to do with the powders used. Extruded powders are notorious for inaccurate powder measuring. Doesn't matter if it's an automatic or the Uniflow that I use. While flake and ball powders are much more consistent I still prefer the old fashioned method of throwing a charge, weighing and trickling to the exact charge weight I want. Over the years I have modernized, I now use an electronic scale instead of a beam. I do have the beam and do check the electronic to beam scale readings and have found that 99%of the time they agree.My ChargeMaster electronic powder measure and scale has been a little inconsistent lately. For example a load that I use 68 grains frequently ends up 68.2 or so. I closely watch as it trickles out the last few kernels of powder and even though it stops and beeps at the programmed 68.0 grains, after flashing the round count the weight returns at something like 68.2 or so. It seems like this happens about 2 or 3 times out of 10.

Any suggestions?

Thanks.

Dan

Electronic scales need to warm up and stabilize. I have found that no matter whether is an RCBS or Hornady scale they need at least 5 minutes warm up before use. Always watch the tare weight when you take whatever you are using to capture the powder off. It should return to the same value each time. If not, this can cause an error of .2 to ,4 grains.

Speed does not always work for the best accuracy.

I agree 100%I don't use an automatic powder dispenser simply because while they do help with volume reloading their accuracy leaves something to be desired. It's not the fault of the powder dispenser it has more to do with the powders used. Extruded powders are notorious for inaccurate powder measuring. Doesn't matter if it's an automatic or the Uniflow that I use. While flake and ball powders are much more consistent I still prefer the old fashioned method of throwing a charge, weighing and trickling to the exact charge weight I want. Over the years I have modernized, I now use an electronic scale instead of a beam. I do have the beam and do check the electronic to beam scale readings and have found that 99%of the time they agree.

Electronic scales need to warm up and stabilize. I have found that no matter whether is an RCBS or Hornady scale they need at least 5 minutes warm up before use. Always watch the tare weight when you take whatever you are using to capture the powder off. It should return to the same value each time. If not, this can cause an error of .2 to ,4 grains.

Speed does not always work for the best accuracy.

Buzzsaw

Well-Known Member

I believe it comes with 3 inserts but I didn't have any trouble with mine.Do you measure the inside diameter of the chargemaster drop tube to find the correct tube to buy. Calipers work?

Critter Picker

Well-Known Member

I was going to stay out of this one, but when I saw Teri Anne's post I just had to chime in. Been using a uni- flow measure,redding trickler, and ohaus 10-10 scale for 50 years. Went to electronic scale about 10 years ago,but kept checking against balance beam. It was dead on 95% of the time, but if I have to check against balance beam why not just use balance beam? I do zero out the balance beam with proper weights. So if I'm weighing 49.8 gr. of powder I zero scale with 49.8 gr. weights.

Wildstreak

Well-Known Member

I feel your pain. I have similar post on this page and a couple other forums. My chargemaster has been the biggest *** I have ever owned. I have tried the straw trick, I have bought the MK machine insert. I let it warm up, I calibrate it before every use, it's not near fluorescent lighting, there are no vents anywhere near it. Any jack you can think of, any trick, I have done it. If I want a charge weight of any kind of powder I have to set it to .3 and sometimes .4 under and it will still over charge. I will literally throw 100+ charges to get 20 correct. It's ridiculous.My ChargeMaster electronic powder measure and scale has been a little inconsistent lately. For example a load that I use 68 grains frequently ends up 68.2 or so. I closely watch as it trickles out the last few kernels of powder and even though it stops and beeps at the programmed 68.0 grains, after flashing the round count the weight returns at something like 68.2 or so. It seems like this happens about 2 or 3 times out of 10.

Any suggestions?

Thanks.

Dan

Mikecr

Well-Known Member

Regardless of your scale type, it's important to learn it.

This is a dynamic measure (not static), so you need to watch it's operation.

Beam scales like any other have dampening -that can be tuned. Electronic scales can be tuned for more than just dampening.

But in the end, the scale operator needs to be able to detect a good result -vs- suspect.

If you watch carefully with the ChargeMaster, you can detect a suspect dispense, and you can detect when it's right on the money (to the kernel). If you seen a clump drop just before the beep, it's and overcharge. If you see it jogging at it's slowest prior to beeping, like it wants one more kernel to fall but it just doesn't happen, and eventually it beeps anyway,, then you know it's an undercharge. If that last kernel had dropped and it immediately beeped, it's on the money right there.

Before long you can get really good at knowing a perfect dispense.

To aid myself in getting there, I purchased a far more accurate Acculab scale to watch the dispensing, the scale response, and then read the real results. Once I had learned the scale, I sold off the Acculab, as the CM scale is a far better general reloading scale.

This learning did not actually me cost that much.

Having done the standard CM mods, I also learned that there was an attribute needed that was not among standard mods.

The overall motor speed needs to be tuned to the particular powder, to get that last kernel drop w/beep.

You can't do this with the programming. But again, this measure is dynamic, and so it can be tuned one way or another.

I put a potentiometer in-line with the motor, with access to it's adjustment, so that I could quickly tune motor speed for optimum with a given powder. With that I was able to better the accuracy of dispensing, to the kernel, which can be higher resolution than the CM scale.

I usually end up slowing overall dispense time 2-5seconds, which is less that programming offers. But this is different. A very fine tune.

I can leave the program in default settings with this.

What RCBS should have done is further deveop the product with a second purpose-built trickler tube, operating in parallel.

A smaller tube and externally adjustable for the particular powder. Stop the big tube under charge, at trickle phase.

This is a dynamic measure (not static), so you need to watch it's operation.

Beam scales like any other have dampening -that can be tuned. Electronic scales can be tuned for more than just dampening.

But in the end, the scale operator needs to be able to detect a good result -vs- suspect.

If you watch carefully with the ChargeMaster, you can detect a suspect dispense, and you can detect when it's right on the money (to the kernel). If you seen a clump drop just before the beep, it's and overcharge. If you see it jogging at it's slowest prior to beeping, like it wants one more kernel to fall but it just doesn't happen, and eventually it beeps anyway,, then you know it's an undercharge. If that last kernel had dropped and it immediately beeped, it's on the money right there.

Before long you can get really good at knowing a perfect dispense.

To aid myself in getting there, I purchased a far more accurate Acculab scale to watch the dispensing, the scale response, and then read the real results. Once I had learned the scale, I sold off the Acculab, as the CM scale is a far better general reloading scale.

This learning did not actually me cost that much.

Having done the standard CM mods, I also learned that there was an attribute needed that was not among standard mods.

The overall motor speed needs to be tuned to the particular powder, to get that last kernel drop w/beep.

You can't do this with the programming. But again, this measure is dynamic, and so it can be tuned one way or another.

I put a potentiometer in-line with the motor, with access to it's adjustment, so that I could quickly tune motor speed for optimum with a given powder. With that I was able to better the accuracy of dispensing, to the kernel, which can be higher resolution than the CM scale.

I usually end up slowing overall dispense time 2-5seconds, which is less that programming offers. But this is different. A very fine tune.

I can leave the program in default settings with this.

What RCBS should have done is further deveop the product with a second purpose-built trickler tube, operating in parallel.

A smaller tube and externally adjustable for the particular powder. Stop the big tube under charge, at trickle phase.

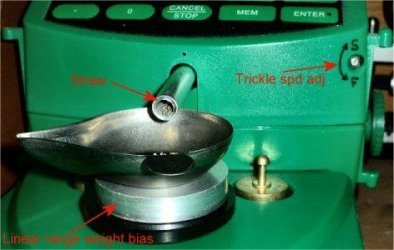

Attachments

fnlights

Well-Known Member

Literally exactly what I do with the same components. I want to buy a more reliable scale than the Frankford to test the chargemaster on, but I have not yet.I've got the Chargemaster Lite, and it does fluctuate a bit. I also have a Frankford electronic scale which is also somewhat accurate, but not perfect. So when I'm doing load development or hunting rounds, I use the Chargemaster to load the pan, then I place the pan on the Frankford scale to verify.

I don't trust either scale completely, but the odds of them both being off the exact same on one load is pretty rare. If it's off more than 0.1 grain, I dump the powder back into the hopper and redo. If it's off twice in a row, I re-calibrate the Chargemaster. Works well for me, just takes a few seconds to measure the charge twice.