kiwi3006

Well-Known Member

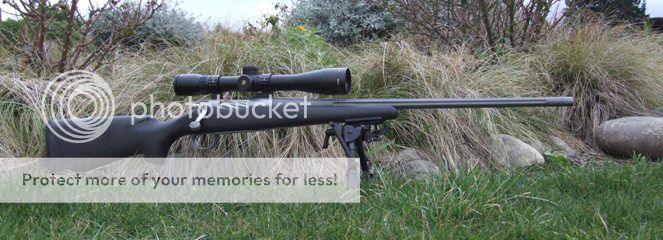

Nice going! I'm putting together a 7 SAUM as well. Slightly different path though. Mine is going to be a lightweight carrying rifle. Based off a Model 7 7 SAUM it should go under 7 lb with a scope.

Factory Model 7 barrel fluted, lightweight firing pin and fluted bolt. Will have a radial muzzle brake. Bushnell 6500 2.5-16x42 scope in Talley lightweight rings.

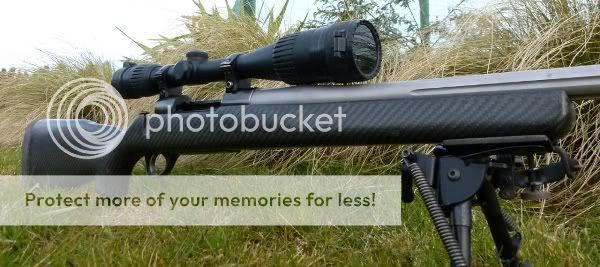

I've nearly finished the carbon fibre stock, should come in at 16-17oz. The stock is a copy of the factory Model 7 stock.

Stu.

Factory Model 7 barrel fluted, lightweight firing pin and fluted bolt. Will have a radial muzzle brake. Bushnell 6500 2.5-16x42 scope in Talley lightweight rings.

I've nearly finished the carbon fibre stock, should come in at 16-17oz. The stock is a copy of the factory Model 7 stock.

Stu.