What I'm saying is it doesn't matter who is right or wrong in it. People have options and they can do what they want which is not a bad thing. As for me, I don't care if I have a 7 PRC or a 7 rem mag. The whole chest pumping thing is not for me either. Just as people chest pump about the 7 PRC or the 7 rem mag, people are gonna chest pump about being right if the 7 PRC doesn't catch on. I'm not about chest pumping anything and don't care for it.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7prc or 7mag

- Thread starter Elk Crazy

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

blksno

Well-Known Member

to me, it depends what bullet you wanna run and if you're interested in a full custom build or not.

If you wanna do a full custom...build a 7 LRM, it's the best of the 7 Rem and the PRC in one pkg. Brass adaptation being the big kick in the nuts.

As for bullet selection (assumign proper twists)

If you wanna run a 150-170 bullet, run a Nosler

If you wanna Run a 170-185, run a 7 Rem Mag with the right twist

If you wanna run a 185-195, run a PRC.

I had interest in the 7 PRC when it was first announced, and when I read the H20 capacity, I lost interest. It doesn't do anything better than a custom 7 Rem Mag with the proper twist. It's only advantage is no belt, which isn't enough for me to switch.

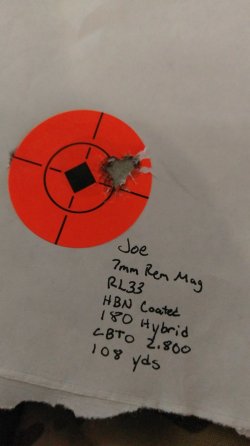

3100 FPS from HBN coated 180 Hybrids smokes anything a PRC will put out, even hand rolled... but it takes the right powder and the right barrel to do it right.

If you wanna do a full custom...build a 7 LRM, it's the best of the 7 Rem and the PRC in one pkg. Brass adaptation being the big kick in the nuts.

As for bullet selection (assumign proper twists)

If you wanna run a 150-170 bullet, run a Nosler

If you wanna Run a 170-185, run a 7 Rem Mag with the right twist

If you wanna run a 185-195, run a PRC.

I had interest in the 7 PRC when it was first announced, and when I read the H20 capacity, I lost interest. It doesn't do anything better than a custom 7 Rem Mag with the proper twist. It's only advantage is no belt, which isn't enough for me to switch.

3100 FPS from HBN coated 180 Hybrids smokes anything a PRC will put out, even hand rolled... but it takes the right powder and the right barrel to do it right.

Attachments

Personally I'd go Seekins, 7 RM (if it has the box length I'd have it punched to 7 Mashburn Super) and I wouldn't worry about the 50-60 fps diff between a 22 and a 24" barrel. Barrel length is for balance not speed (at least it is for me)

Best of luck to ya

Best of luck to ya

bballard

Well-Known Member

Please try a nosler model 21! It's a very well balanced rifle! Love mine!I'm all ears? I just want a quality rifle that shoots through the same hole. Don't say Christensen though…those are fn terrible

Good article ( show) on YouTube recently...search Ultimate Reloader 7 mag vs 7 PRC. Not enough difference for me to buy one but that's just me. Check for Brass first would be my only concern..... To sum up the difference in the show.....68fps at 1000 yards...won't light my world on fire....but 11" flatter at 1000.... again is that enough???? If you aren't competing in BR.....??? Just me...

One thing to consider are you reloading or shooting factory ammo? Most of the 7 prc factory rifles with a saami chamber will have issues after a few firings with anything but Hornady brass. It's well documented. The rear of the chamber is too small. As long as you can get the right twist in a barrel I like the 7 mag. The prc chamber design is a little better with throat angle but it's not that big a deal.

fseaman

Well-Known Member

Do you mean assuming SAMMI or CIP originally specified twist rate?As for bullet selection (assumign proper twists)

If you wanna run a 150-170 bullet, run a Nosler

If you wanna Run a 170-185, run a 7 Rem Mag with the right twist

If you wanna run a 185-195, run a PRC.

28 Nosler seems to be specified as 1:9

7 Rem Mag seems to be specified as 1:9.5

7 PRC seems to be specified as 1:8

However, not every rifle manufacturer sticks to that exactly. A builder doesn't have to use "proper" twist rate.

My Semi-Custom 260 and DTA SRS were built/bought before the 6.5 CM was created and have tighter twist than "proper".

The semi-custom 260 Rem is 1:8 like a 6.5 ManBun

Creedmoor lovers, I get it, don't be haters. The "advantage" of a 6.5 CM over a 260 is twist rate. Make the 260 with the same twist and that "advantage" goes away. Sure, you can then go to COAL and just nit pick it to death. Boring.

Weatherby Mark V uses 1:8 for 7mm PRC and 1:9 for the Nosler and Rem Mag making bullet range the same for the Nosler and Rem Mag. They offer up to 180 Berger VLD factory load for the 28 Nosler. Interesting that for the 7mm PRC, Weatherby goes to the 177 Hammer Hunter but the 28 gets the 165 Hammer Hunter. Remember Weatherby "guarantee" sub-moa with Weatherby ammo.

A Weatherby Vanguard 7 Rem Mag is going to be original spec 1:9.5. Japanese adherence to specifications?

The point of all that is that bullet weight is not as tightly coupled to chambering as "proper" suggest. Any builder, be it factory, semi-custom or full custom can choose any twist rate for any caliber+chambering as desired. I certainly do.