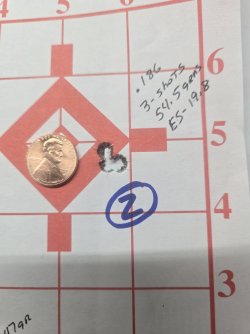

I'm probably going to hear a lot of grief, that's ok but with ADG and Lapua brass, I pull it out the box and start loading. If necks are severely bent I'll address it, but otherwise I do nothing. I just did a load test yesterday with my 6.5 PRC, 3 shots at 100 as I was testing 2 powders. This was my best group with first load test, Lapua brass right out of the box.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What process for new brass…

- Thread starter coastrange

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Revolting Peasant

Well-Known Member

^^^this^^

Thank you!

I might use a mandrel if there are neck dents.

High quality premium brass shouldn't need a lot of extra work. That's why you pay the extra money.

Just me and my opinion for my usage.

Does it make a repeatable, consistent difference on the target is the question I always ask myself.

Thank you!

I might use a mandrel if there are neck dents.

High quality premium brass shouldn't need a lot of extra work. That's why you pay the extra money.

Just me and my opinion for my usage.

Does it make a repeatable, consistent difference on the target is the question I always ask myself.

Last edited:

DLJ6

Well-Known Member

Nice work. Care to share the bullet and powder details?I'm probably going to hear a lot of grief, that's ok but with ADG and Lapua brass, I pull it out the box and start loading. If necks are severely bent I'll address it, but otherwise I do nothing. I just did a load test yesterday with my 6.5 PRC, 3 shots at 100 as I was testing 2 powders. This was my best group with first load test, Lapua brass right out of the box.

I'm probably going to hear a lot of grief, that's ok but with ADG and Lapua brass, I pull it out the box and start loading. If necks are severely bent I'll address it, but otherwise I do nothing. I just did a load test yesterday with my 6.5 PRC, 3 shots at 100 as I was testing 2 powders. This was my best group with first load test, Lapua brass right out of the box.

I do the same, just chamfer and debur

KsKevin

Well-Known Member

I neck size & mandrel, trim so all are exactly same length, chamfer in & out, debur flash holes.

I used Reloder 26 (54.5gr. that particular group) with a 147 gr. Hornady ELD-M, Lapua brass and Federal 210M primers. I was also comparing Midwest Powders MP-711 which is supposed to be similar to Reloder 26. I tested it, (first time trying it) against the same grain weight as the Reloder 26. I found it to be on average about 90 FPS slower but the extreme spread was only 8-11 on 4 tests I performed. Best group with it in that test was .400 and worst .610. It looks to be a promising powder albeit a little slower. Forgot to say barrel is 1-7.5 twist.Nice work. Care to share the bullet and powder details?

coastrange

Member

Ok lots of answers just as expected. I just listened to a podcast with adg about new case prep and they recommended doing exactly what you would do with fired brass for consistency.

I've only ever used full length dies, using it intact with expander, but a buddy swore by a Lee collet die so I picked on up.

Now I'm going down the expander mandrel rabbit hole (again) to be honest every web page or thread I read goes back and forth. It's a lot to figure out

I've only ever used full length dies, using it intact with expander, but a buddy swore by a Lee collet die so I picked on up.

Now I'm going down the expander mandrel rabbit hole (again) to be honest every web page or thread I read goes back and forth. It's a lot to figure out

Buckskinner

Well-Known Member

Use quality brass, prime, powder, seat, fire. If you have a solid rifle setup you do not need to chase the dragon with brass prep. Don't get me wrong, I've done all of it and finally figured out that trying to sew a purse from a pigs ear is more trouble than it's worth and a quality rifle pays dividends in the long run.

This target was at 410 yards with 6.5 PRC, less than 10 rounds through the barrel with new brass, mild load, middle of the road seating depth. 100 yards was target similar to Tim's so I figured I'd stretch it out a little. I have several rifles that are accommodating like or close to this and have had many that weren't, and they are gone. I don't chase dragons anymore...

This target was at 410 yards with 6.5 PRC, less than 10 rounds through the barrel with new brass, mild load, middle of the road seating depth. 100 yards was target similar to Tim's so I figured I'd stretch it out a little. I have several rifles that are accommodating like or close to this and have had many that weren't, and they are gone. I don't chase dragons anymore...

Attachments

Manufacturing brass is very rough on the case. Some do a far better job than others at taking care of them throughout production.

Leaving the annealing discoloration is a milspec requirement. Many will clean after annealing if not going to Uncle Sam. This really helps bullet seating consistency but is hard on neck geometry.

So…at a minimum run a mandrel down the neck. After that do what your process tells you what is needed.

Like others have stated, I treat every piece of brass the same.

Exception - Fireforming for Wildcats

Leaving the annealing discoloration is a milspec requirement. Many will clean after annealing if not going to Uncle Sam. This really helps bullet seating consistency but is hard on neck geometry.

So…at a minimum run a mandrel down the neck. After that do what your process tells you what is needed.

Like others have stated, I treat every piece of brass the same.

Exception - Fireforming for Wildcats

Seabeeken

Well-Known Member

If the rifle is properly headspaced as Ackley intended, there is no need for false shoulders.I have 6-8 ai chambers and never needed a false shoulderYou'll get better, more accurate, straighter brass if you mandrel the necks up to 6.5 and then create a false shoulder with a full length Ackley die. But do as you wish.

Warrenoliver

Well-Known Member

Brass needs to be fire formed to your rifle anyway so just run a sizing mandrel through the neck to straighten any dings. If you don't have a mandrel, just run your resizing die button through the neck without touching the shoulder

6.5x300 WBY

Well-Known Member

I'm pretty simple in my approach for my 3 rifles. My 6.5x300 and my 338-378 get FL sized, chamfer, debur, Prime, powder, bullet, shoot.

30-06 to - [ AI ] got chamfer, debur, prime , powder, bullet shoot. Near max load 2 grains under approximately. Brass came out beautifully. Nice consistent 30-06 AI case.

30-06 to - [ AI ] got chamfer, debur, prime , powder, bullet shoot. Near max load 2 grains under approximately. Brass came out beautifully. Nice consistent 30-06 AI case.

Sdvldog1371

Well-Known Member

Graphite lube, mandrel the necks, run everything over the Giraud to ensure all necks are trimmed, chamfered and deburred, nylon brush on the case prep station to remove shavings from the beck surface. And load them.

For me the mandrel step is just ensuring the necks are round before chamfer and debur, nothing to do with trying to set neck tension.

For me the mandrel step is just ensuring the necks are round before chamfer and debur, nothing to do with trying to set neck tension.

Similar threads

- Replies

- 14

- Views

- 4K