Justice1327

Well-Known Member

6MM Creed—- Need some help with this barrel. This is a Preferred Barrel blanks barrel. I'm using short action Customs modular dies , Nexus press/Co-Ax, mandrel for a 2.5thou neck interference fit, Alpha virgin brass, CPS at 5thou crush, CCI450, H4350, V4 pwdr dispenser, 103gELDX, Defiance Classic in bedded McMillian , (I have put it in a chassis, and it shoots the same) weather: 75d, humidity85%, 2-5mph wind. Group was shot and then I used an air cooler to cool the barrel to where it is just warm to the touch. It is a .810 diameter barrel w/ a 7.5tw. SRS 3 port brake. Breathing was good and I had a good trigger press except for 2 or 3 shots. 12pwr SS scope. I've checked the scope screws, muzzle brake, action screws, and all our tight. Shooting off a rest. Any help to tightened up the groups is appreciated.

I am thinking about changing the bullet first. But the guy who has this Rifle really wanted to use the 103 ELDX

Also, I'm thinking about switching powders to superperformance or RL 17/19

100Rds

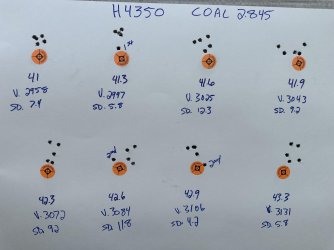

Slightly heavy bolt lift at 43.3

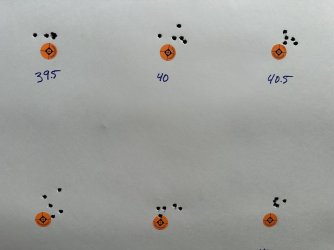

First pic with a COAL of 2.795

Bottom row is 41/41.5/42g

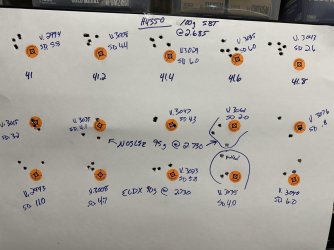

Added third pic with various bullets

I am thinking about changing the bullet first. But the guy who has this Rifle really wanted to use the 103 ELDX

Also, I'm thinking about switching powders to superperformance or RL 17/19

100Rds

Slightly heavy bolt lift at 43.3

First pic with a COAL of 2.795

Bottom row is 41/41.5/42g

Added third pic with various bullets

Attachments

Last edited: