ntsqd

Well-Known Member

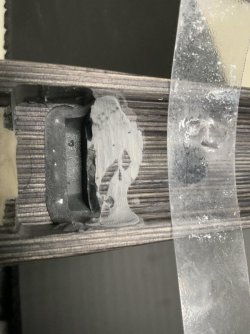

I'm very far from being an expert, but I've come to the conclusion with wood or composite stocks lacking a bedding block that bedding without pillars is a waste of time. I bed in a two step process too. I bond the pillars in place to set the height before relieving the stock for bedding material.

As to the OP's actual question, I've long felt that bedding to roughly the body to shoulder corner of the chamber is a reasonable RoT if I'm going to bed forward of the lug at all. As to when I do or don't bed forward, I don't have any RoT for that. If the barreled action looks like it should be, then I bed forward. If it doesn't, then I don't. It's not a Rule, it's an intuition.

As to the OP's actual question, I've long felt that bedding to roughly the body to shoulder corner of the chamber is a reasonable RoT if I'm going to bed forward of the lug at all. As to when I do or don't bed forward, I don't have any RoT for that. If the barreled action looks like it should be, then I bed forward. If it doesn't, then I don't. It's not a Rule, it's an intuition.