I have noticed that they tend to be in pockets and that for a few years most of the coyotes in an area will be close to the same color faze, I think that if they were checked they would all be related to each other, with the area spreading out like if you were to pour water on a flat cement floor. It's pretty interesting how the coyotes are, some of them have strong dominate personalities and they will pass that on to their young along with their color faze. Then over a few to several years those traits will get diluted with other genes from surrounding areas and you will see other traits become more dominate in that area. I have also found that when I thin an area out that the remaining coyotes will be more cautious, maybe they were and that has kept them alive or maybe they are just a little more on edge because they are by themselves, like when they are during fall dispersal or at the beginning of breeding season and looking for a mate so are trespassing and exploring new territories.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ramblings and Such From Hunting Coyote

- Thread starter DSheetz

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

We have both but the deep reddish color is most prevelant. Back in the early 80's my relatives in this area that were probably some of the most accomplished hunters, trappers and fisherman in the county killed several what they said were red wolves. They had killed and trapped hundreds of coyotes and this was no coyote. Of course the DNR had nothing to say on the matter which is normal for IL. It stands to reason that this is possibly where this color phase came from. I've seen many pictures from back in the day and the coyotes were not that color back then. Genetics can be a very interesting AND confusing subject lol. Dominant and recessive traits on both parents play big roles, ie, breed any color bovine to another that's angus or high percentage of angus and the calf will be black, almost always. Black is the dominant gene. All this brings back memories of high school biology class and making up punnent squares lol.

It was in the late 70's and early 80's that the red wolves were introduced in that part of the world, mainly on the east coast, but having four paw drive and new to that area they soon dispersed to other areas. If a person believes the DNA studies that have been done on coyotes and Illinois was one of the states that did a large study, most of the coyotes have a large percentage of their population that does indeed have wolf genes in them. Only about 3 percent of them have domestic dog genes in them. The ones in Illinois do tend to have more red wolf in the lower part of the state with the northern areas having timber wolf being more prevalent due to the closeness to Canada and other areas that have them. Genetics is indeed an interesting field and then after several generations a trait that has laid dormant for several generations will surface seemingly out of thin air. In the 50's and 60's a lot of studies were done involving coyotes and their breeding patterns as well as their dispersal patterns. Some of them moved up to 400 miles from where they were born while others stayed within a few miles of where they were born wolves tend to be the same from the studies that I have read. I don't know if the studies from the earlier years done by the USDA, Texas State and Souther California State, are still available now, but there are several newer studies that are at this time. To me it was and is about knowing my opponent, they aren't my enemy I don't have a hatred of them I tend to kind have a lot of respect for them, especially in that they both or often three of them will take part in keeping the pups alive and teaching them, but I also know very well that when they come into conflict with humans doing the same for their family they are the ones that need to be taken out of the equation. I am seeing in my area that the pups are dispersing about a month and half later than normal this year, they are just now starting to move around on their own and in small groups of this year's pups. I think that the lack of prey is a large contributing factor.

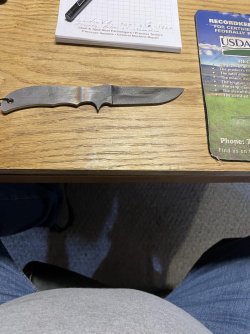

The heating and quenching then crio treating is completed, three heats to 1450F then quenched in my 125-f quenching oil, with three 24-hour crio cycles after the heats and quenches, it will be heated to 350F and held for 2 hours now that I am finished with the rough grinding. Then after the drawing it back from brittle to hard and tough but not brittle the finish hand work starts. At this time, I have less then 5 hours total time in this one. If I were going to put scales on the handle, I would have another hour or hour and a half in roughing them out drilling the rivet holes and cutting the brass rivets and the brass lanyard tubing. It gets a choil cut in the blade and more polishing and hand grinding to refine the shape. The blade will get some tape applied to it so that I don't end up needing stiches while the finishing is being done. Into the oven now for the draw back heating. One of the good things is that once you get the grain structure of the steel refined it doesn't care how long you take to get around to finishing it. So, for three or four days I have been doing other things, I put a new blade in a folding knife for a friend, showed some younger guys a few tips on their snares and line and helping around the house just your normal everyday things that need getting done before the snow and cold set in for a couple of months.

Attachments

Straight Shooter

Well-Known Member

I want that one.

Sorry guys that one goes on my pistol belt, for when I'm hunting, trapping, fishing, or just out and about. I do like the look and feel of it. It's just a fixed blade version of my folding knife without scales on the handle. Several years back I found a spring assist opening knife, that was a good fit and feel to me with good looks, but the blade material wasn't quite what I wanted, so I made a new blade for it. It's a Kershaw Volt II. Over the years I've made several blades for them and did some heat treating of the blades they come with. There are probably 20 or 30 of the ones I've played with floating around the United States, a couple of them even deployed overseas and one or two of them are in first responder's kits, so I thought that I would make myself a fixed blade version for my pistol belt.

Yes, they are and when you find one that is just an extension of you it makes it so much better to use. And that is why I make changes to my pistols and rifles, so they just become another part of my anatomy when I use them, accuracy is one thing and precision is another thing. Precision is better achieved by tools that fit and feel good to you, not things that are awkward, clumsy and ill fitting, but that's just me.

EXACTLY!!!Yes, they are and when you find one that is just an extension of you it makes it so much better to use. And that is why I make changes to my pistols and rifles, so they just become another part of my anatomy when I use them, accuracy is one thing and precision is another thing. Precision is better achieved by tools that fit and feel good to you, not things that are awkward, clumsy and ill fitting, but that's just me.

Laid out drilled and pinned for the rough grinding on a couple of material removal knives made out of 52-100 bearing steel. Of the last 8 coyotes I have taken 6 have been males. That tells me that any available female that cycles this season won't have a problem finding a mate. Walt and I went out north this morning to look around and found some good sign, a lot of tracking and found some good tracks, from the size of them it was a pair of males traveling together in one area and a pair with one male and female in another pasture. we will get out into some other pastures later this week. I have an AR15 in 223 Wylde to put a free-floating hand guard on and time the adaptor for a suppressor on. It's a side charging smooth side upper receiver I think he wants it cera coated in flat dark earth to match his new hand guard I will ask him to make sure. I had him testing a knife for me he said that it didn't hold an edge as well as the 52-100 blade I had him try out that didn't work as a pry bar but held a good edge. I told him that I would make one of the 52-100 blades for him, but it would be a while before I got around to it, he will just have to sharpen the other one more often till that happens. I made one for one of my brothers-in-laws he thought he should be able to use it as a pry bar also I told him you're a mechanic you know better than that. I have given you pry bars, and you have boughten some and I have told you that screw drivers aren't prybars either. I don't have time to get the right tool for the job till after I break the wrong tool and mess things up so it takes me longer than it would have to get the correct tools. I have to smile shake my head and walk away. I used to be annal retentive about things like that, but people are people and that is just the way life is.

Attachments

Brother Buckwheat

Well-Known Member

- Joined

- Jan 9, 2014

- Messages

- 67

That's the way I feel about tools when working, if they are used for a specific job, use that tool for that job. Just rebuilt 2 hydraulic cylinders for a buddies forklift, rebuild job took 4 hours for both, waited on the tool to disassemble the cylinders for 5 days. I've seen "mechanics" uncap the cylinders with a drift punch and a 3-lb'er, I cringe. Job done right.Laid out drilled and pinned for the rough grinding on a couple of material removal knives made out of 52-100 bearing steel. Of the last 8 coyotes I have taken 6 have been males. That tells me that any available female that cycles this season won't have a problem finding a mate. Walt and I went out north this morning to look around and found some good sign, a lot of tracking and found some good tracks, from the size of them it was a pair of males traveling together in one area and a pair with one male and female in another pasture. we will get out into some other pastures later this week. I have an AR15 in 223 Wylde to put a free-floating hand guard on and time the adaptor for a suppressor on. It's a side charging smooth side upper receiver I think he wants it cera coated in flat dark earth to match his new hand guard I will ask him to make sure. I had him testing a knife for me he said that it didn't hold an edge as well as the 52-100 blade I had him try out that didn't work as a pry bar but held a good edge. I told him that I would make one of the 52-100 blades for him, but it would be a while before I got around to it, he will just have to sharpen the other one more often till that happens. I made one for one of my brothers-in-laws he thought he should be able to use it as a pry bar also I told him you're a mechanic you know better than that. I have given you pry bars, and you have boughten some and I have told you that screw drivers aren't prybars either. I don't have time to get the right tool for the job till after I break the wrong tool and mess things up so it takes me longer than it would have to get the correct tools. I have to smile shake my head and walk away. I used to be annal retentive about things like that, but people are people and that is just the way life is.

Heading to the cabin tomorrow since I haven't been there since before the beginning of deer season in July. Just built a 6.5 Grendel so going to break in the barrel tomorrow and perhaps go to the back of the property and see if we can find any furry dogs to poke on Thursday and Friday.

I miss the Wyoming country and my friends in Casper.