Haven't had a rifle or scope failure in 50+ years of hunting(KNOCK WOOD!!!)

I have shot various forms of rifle competition for about the same length of time. The combination of my own experience as well as observing other shooters gives a good sense of the "watch-outs", avoidances, and preventive maintenance aspects with certain designs and products….And applied them to my hunting rifles. Some have been addressed/changed over time by the manufactures, others have not, and are inherent.

Surely don't want to knock any design or manufacturer…Some of the things that come to mind:

-Beware of "used: scopes, and scopes that have lower competitive price points , "and a reputation for superb, fast-turnaround service".

-Routinely check the magazine/follower spring tension and proper placement on push-feed bolt action designs, particularly with heavier weight cartridges. If the spring tension is off, it will cause a feeding/timing issue. If all else seems fine, try a new spring…Also, check the tension "under firing" of the floor plate latch(if present).

-If a Savage AccuTrigger is set too lightly, or the improper spring is used(target vs standard) the spring can dis-lodge during use and render the trigger in-operable. The same goes for "lightly adjusted" original design Model 70 triggers. Either design, when properly set up have been quite reliable for me. .

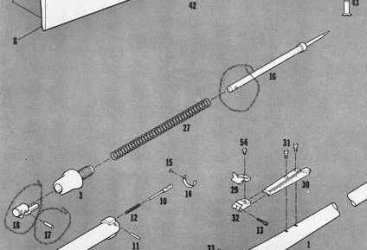

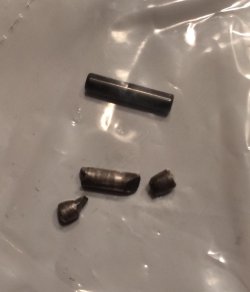

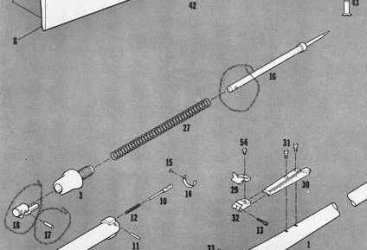

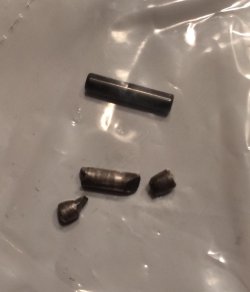

-Mentioned by MagnumMania….The pin that attaches the bolt head to the firing pin on the Remington 700/clones is prone to breakage, particularly with high volume use, heavy recoiling cartridges, or high volume dry firing. I have experienced this myself and observed it with other shooters quite a few times(during competition). It might look OK by simply observing the cocking/firing pin assembly, but the pin can be "cracked" while in the assembled state…but rendering the bolt inoperable. It's easy to check/inspect, and the pin can be easily replaced for a few dollars. I keep a couple on hand for my high volume rifles and change them every thousand rounds or so. Shown new and damaged pins. Diagram #17.