I know AR barrels are different but they recommend between 30 to 80lb ft. I personally don't like to torque a barrel nut on an AR past 50 and would rather shim it than go over that. For my Remage barrel the recommended torque was 50 ft lbs. I was reading just the other day about shouldered prefits in a switch barrel setup and the recommendation was just past hand tight for a barrel with right hand twist. The theory was that with right hand twist the torque from firing will actually snug the barrel with each shot. Not quite sure I subscribe to that theory so don't shoot the messenger. Just repeating what I read.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel torque and headspace

- Thread starter hemiford

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

dfanonymous

Well-Known Member

- Joined

- Jul 16, 2016

- Messages

- 2,321

That's the thing about "torque specs." They are generally issued at a point where there is a safe yield point.did you only move it .00173 inches ? (1/36 of a rotation) Or did you just stretch the threads ?

You could tighten it with torque, mark it with a sharpie, and then take it off, lubricate it, hand tighten it, then torque it to where your lines match up.

Being consistent is the key if you plan to take the barrel on and off, which is why I'm assuming you want to lubricate it in the first place. As long as the barrel is cut square and you line your lines up, you should be ok.

I personally just burn out the barrel and switch to the next one. I'm never worried about swapping barrels or taking them on or off.

dfanonymous

Well-Known Member

- Joined

- Jul 16, 2016

- Messages

- 2,321

"Bench rest shooters" also use to hand tighten barrels. I would take what they say with a grain of salt. Over tightening is a thing, so is under tightening.Utah state Benchrest shooter, Steve Hendrey was a tooling engineer at the Jet aircraft repair facility in Ogden Utah. Steve was a master machinist. They found that some barrels resonate to a point where they loosen. Tightening the barrels to 100 fixed a lot of accuracy issues on the custom BR guns. I suspect that 60-75 maybe plenty. Some of the best benchrest gunsmiths torque to 100, and they do put a little lube on the shoulder face which will make many heads explode...these are some of the best benchrest gunsmiths in the world.

There is also much talk on a loose thread for a remington barrel tenon vs one that leans between a class 2 and 3 where Steve was a firm believer in a looser fit for Remingtons.

Changing Barrels

If I want to change barrels on, say, a BAT action do I need to worry about headspace or how tight to torque the barrel -- assuming the new barrel is/was chambered and threaded by a competent gunsmith? If so, what do I need to do? Would it matter if the old and new barrels were...

I have been at a benchrest match, used a strap wrench to unscrew a barrel, screwed on a new barrel. I put the butt stock between my two feet, and snapped the barrel in place by hand. Then, I went back to shooting. The way the barrels were indicated in during chambering got the point of impact within 3" of the previous barrel or closer.

Having said this, it does not mean that the barrel would not shoot loose.

Having said this, it does not mean that the barrel would not shoot loose.

I think that the actual point here is that the at least this way the barrel wants to tighten - not loosen - with firing.I know AR barrels are different but they recommend between 30 to 80lb ft. I personally don't like to torque a barrel nut on an AR past 50 and would rather shim it than go over that. For my Remage barrel the recommended torque was 50 ft lbs. I was reading just the other day about shouldered prefits in a switch barrel setup and the recommendation was just past hand tight for a barrel with right hand twist. The theory was that with right hand twist the torque from firing will actually snug the barrel with each shot. Not quite sure I subscribe to that theory so don't shoot the messenger. Just repeating what I read.

MagnumManiac

Well-Known Member

On the subject of torque in other areas of tec I'm always surprised how many people don't stop to ask if it's a wet or dry torque or even understand the difference.

As a qualified engine builder, where I learnt machining, I know there is a real difference to not only wet or dry torque, but also WHERE the lube goes and WHAT type it is also makes a difference.

I only use nickel ant-seize on my barrel threads, but seeing that the barrel torque doesn't have a lot of stress on it it anyway, torque rating doesn't really matter.

The factories use such high torque, and often a thread locker, because they don't want Bubba tinkering…

Cheers.

This is what I use for engine bolts/nuts.

Attachments

I am interested in what you know about this

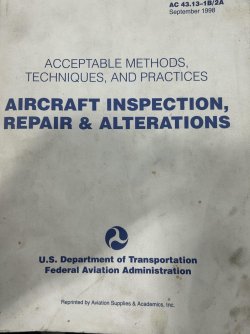

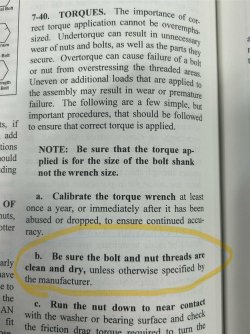

Here's what I was talking about. Keep in mind this is from the small world of aircraft I don't claim to be any type of expert on anything.I don't know about torquing barrels, but on screws and nuts, always suggested to use lubricant before torquing, I do this on ring to base and ring to ring screws

The first attachment is standard aircraft practices. It says that threads should be clean and dry unless manufacture recommends otherwise.

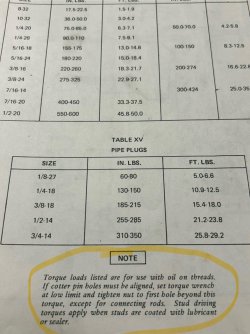

The third is an aircraft engine overhaul manual and in the note at bottom of pages says these specs are wet threads with oil.

Some other manufacturers give two specs both wet and dry and they are quite different.

I personally don't think for barrels it's really that critical what exact number I only mentioned there being a difference definitely wasn't trying to claim any knowledge as it pertains to barrels.

Attachments

- Joined

- Jan 26, 2015

- Messages

- 1,821

A barrel shoulder may "crush" .001-.002" on initial torque, depending on value. It can be accounted for in the chambering, but in practical application, .001"will rarely make a difference in the chambering (though it's more critical in an AI chambering).

Stainless on Stainless...use lube or get galling....even on muzzle breaks. Some lubes will dry out with barrel heat, consider that. I stopped using some popular anti-seize years ago after shooting hot barrels on p. dog towns, the anti-seize turned to what looked like dried cornflakes.

Shell 33MS is an excellent, aircraft application, so, using on barrels is a superb application.

2AtacticalNH.com has this product and 12 oz will last you a lifetime

Another is Molykote from Dow Corning, P37 Antiseize paste

Both of these products are good for 1400* and prevent seizures after long exposure to heat.

Shell 33MS is an excellent, aircraft application, so, using on barrels is a superb application.

2AtacticalNH.com has this product and 12 oz will last you a lifetime

Another is Molykote from Dow Corning, P37 Antiseize paste

Both of these products are good for 1400* and prevent seizures after long exposure to heat.

AeroShell 33ms Barrel & Nut Lithium Moly Synthetic Grease-Mil Spec (Select Qty) | eBay

Find many great new & used options and get the best deals for AeroShell 33ms Barrel & Nut Lithium Moly Synthetic Grease-Mil Spec (Select Qty) at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Aeroshell 33 33ms grease expired | eBay

These are being sold for nostalgia only-I believe they are expired and it is not to be used for anything but your man cave-

www.ebay.com

Last edited:

Hugnot

Well-Known Member

I am guessing that applying 100 ft/lbs of torque on a 1.2 inch diameter unlubricated threaded bolt would result in about 5,000 lbs of force/tension/compression. Lubrication might increase it to over 8,000 pounds. All this compression could affect any contact surfaces

Last edited:

Thank you for the informationHere's what I was talking about. Keep in mind this is from the small world of aircraft I don't claim to be any type of expert on anything.

The first attachment is standard aircraft practices. It says that threads should be clean and dry unless manufacture recommends otherwise.

The third is an aircraft engine overhaul manual and in the note at bottom of pages says these specs are wet threads with oil.

Some other manufacturers give two specs both wet and dry and they are quite different.

I personally don't think for barrels it's really that critical what exact number I only mentioned there being a difference definitely wasn't trying to claim any knowledge as it pertains to barrels.

As the Rockwell hardness between two mating metals becomes very close or the same, hauling will happen. Lube frequently is critical, and the same applies to bolt lugs.

Useful temperature operating range of Aeroshell 33 is -73C to +121C, good stuff too. Aircraft Spruce and Specialty has the Aeroshell 64 for $24.50 for a 14 oz tube. Those expiration dates are mainly if a guy's greasing up the Airbus or Boeing stuff.Stainless on Stainless...use lube or get galling....even on muzzle breaks. Some lubes will dry out with barrel heat, consider that. I stopped using some popular anti-seize years ago after shooting hot barrels on p. dog towns, the anti-seize turned to what looked like dried cornflakes.

Shell 33MS is an excellent, aircraft application, so, using on barrels is a superb application.

2AtacticalNH.com has this product and 12 oz will last you a lifetime

Another is Molykote from Dow Corning, P37 Antiseize paste

Both of these products are good for 1400* and prevent seizures after long exposure to heat.

AeroShell 33ms Barrel & Nut Lithium Moly Synthetic Grease-Mil Spec (Select Qty) | eBay

Find many great new & used options and get the best deals for AeroShell 33ms Barrel & Nut Lithium Moly Synthetic Grease-Mil Spec (Select Qty) at the best online prices at eBay! Free shipping for many products!www.ebay.com

Aeroshell 33 33ms grease expired | eBay

These are being sold for nostalgia only-I believe they are expired and it is not to be used for anything but your man cave-www.ebay.com

Last edited: