Wanted to add that really for our type of shooting the fluting effects on barrel temp is sort of a red herring as its application is just not that significant. Barrel stiffness or how it effect barrel "whip" harmoinc can lead to some very interesting possibilities. But most peopke on hunting rifles do it to control where the mass is in the barrel or control weight and finally just for looks. You can have some very interesting discussions and designs if you have a few good long talks and idea sharing with very knowledgable structural engineers. Combine this with the capability of these cnc machines can be surprising.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone use fluted barrels?

- Thread starter 806 guns

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

So then the main benefit of fluting comes from comparing two different barrels. The advantage would be the fatter one would heat slower and cool faster compared to the thinner barrel without flutes, but with no weight penalty.That is generally correct.

Where if you have a 3.5 lb 2b contour barrel then took a rem sendero/varmint contour which starts @ just shy of 5lb and fluted it to where it weighed 3.5lbs it would nave more surface area. The amount could vary significantly based on the design profile of the fluting.

Fluting wouid be very different if naximum cool vs maximum stiffness vs combo blending the two for best compromise of both

This is the first time Ive heard of the weight savings being worth it. Its hard for a new person to custom barrels to put this all together the info comparing how much weight is removed isn't really out there. I went thru this with my first custom barrel, chose fluting by the way but only because I was hoping the build would be lighter weight. So maybe I should let go the mental conflict if I should have got the next lighter size barrel, I knew I did want to gain at least a couple more shots before heat affected POI. It sounds like with a little luck, I made the right choice.

Appreciate the reply and info.

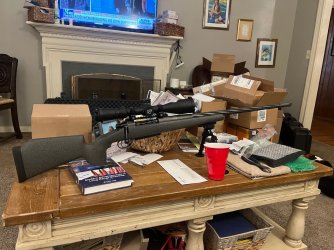

Not a UL by any means, but as an example this 300 PRC has a Rem Varmint with 6 flutes @ 22" length and 1.0 lbs was removed from it with fluting. Rifle weighs 10 lbs 2.3 oz with scope.

Barrel cost with shipping: $500

Cost of fluting (no shipping) $165

Barrel cost with shipping: $500

Cost of fluting (no shipping) $165

Sweet looking rifle!Not a UL by any means, but as an example this 300 PRC has a Rem Varmint with 6 flutes @ 22" length and 1.0 lbs was removed from it with fluting. Rifle weighs 10 lbs 2.3 oz with scope.

Barrel cost with shipping: $500

Cost of fluting (no shipping) $165

View attachment 599619

What action is that?

Have almost the exact same barrel spec and fluting Sendro spiral but chambered in 338 Mega @ 21.5" Bart 9.3T 5R, SCS Ti Pro 3, trued Sako 85 L 2lb trigger. Mine with a Trij TenMile 3.5-18x44 comes in @ 9.75lb ready to hunt. That 9-10lb is a sweet spot for me.

Last edited:

Sweet looking rifle!

What action is that?

Have almost the exact same barrel spec and fluting Sendro spiral but chambered in 338 Mega @ 21.5" Bart 9.3T 5R, SCS Ti Pro 3, trued Sako 85 L 2lb trigger. Mine with a Trij TenMile 3.5-18x44 comes in @ 9.75lb ready to hunt. That 9-10lb is a sweet spot for me.

Defiance Classic

RichCoyle

Well-Known Member

Well then the flutes arent helping keep the barrel cool. To me thats a cold bore zero not a string of fire but I know everyone has their own technique.

I guess. I would not shoot a 10-shot group with a hunting magnum.

I had a 26-in heavy barrel 223 Savage that I shot 10 shots many times without letting the barrel cool. Typical 7/16" 10 shot group at 100 yd and a 7/8 in 10-shot group at 200 yd.

Elk Hunter 338

Official LRH Sponsor

FUNNY AZZZZ!!!!I'd like to weigh my Bart #4 that's fluted 3/8x5 I think.

But the Boss Man at LPR used about a 36" pipe wrench and spot tigged it for good measure. Maybe it's cross- threaded too.

It's been good for 1.75-2.25" at 500yds, over about 2-3 different sessions though!

Snake River did the flootin'

Kampfeld Customs did the fluting.I'd like to weigh my Bart #4 that's fluted 3/8x5 I think.

But the Boss Man at LPR used about a 36" pipe wrench and spot tigged it for good measure. Maybe it's cross- threaded too.

It's been good for 1.75-2.25" at 500yds, over about 2-3 different sessions though!

Snake River did the flootin'

Not Snake River, BossMan corrected Me.

Attachments

ntsqd

Well-Known Member

A really fast surface area experiment. Total guesses at all of the dims, but these are they:

24.00 long

Ø.308 cylindrical hole.

Ø1.06 X 2.00 long Tenon

Ø1.25 max diameter at shoulder, no straight/cylindrical section, tapers from there to muzzle

Ø.875 muzzle diameter, 90° flat crown

carbon steel

R.1875 flute "cutter"

Six straight flutes with 15° lead-in angle, Ø.750 minimum diameter (at bottom of the flutes), R3.00 transition radius, Straight portion of flute starts at 5.875 from breach and ends at 2.415 from muzzle, 25° lead-out angle with R3.00 transition radius.

I mention all of this detail in case someone else wants to see if they get the same results or not.

Unfluted it "weighs" 5.55 lbs and has a surface area of 105.02 square inches.

Fluted it weighs 4.45 lbs and has a surface area of 115.53 square inches.

By my math that is only a 10% gain in surface area. From messing around with these models it is very easy to make that number far lower as these flutes are pretty deep in a barrel contour that is pretty stout.

Next I looked at bending stiffness. I held the tenon fixed and put a 100 lbs downward force on the muzzle.

Unfluted exaggerated deflection diagram:

Fluted exaggerated deflection diagram:

Comparing the two peak deflection numbers the fluted barrel deflected down ~.06" more than did the unfluted barrel. That's roughly 60% more deflection!

I have not had time to perform a reality check on these results. I trust the process, these just aren't quite the numbers that I was expecting to see. Assuming that these results are valid this says that a fluted barrel is NOT stiffer than the same profile unfluted barrel. I was expecting that unfluted would be stiffer, but not by such a large margin.

24.00 long

Ø.308 cylindrical hole.

Ø1.06 X 2.00 long Tenon

Ø1.25 max diameter at shoulder, no straight/cylindrical section, tapers from there to muzzle

Ø.875 muzzle diameter, 90° flat crown

carbon steel

R.1875 flute "cutter"

Six straight flutes with 15° lead-in angle, Ø.750 minimum diameter (at bottom of the flutes), R3.00 transition radius, Straight portion of flute starts at 5.875 from breach and ends at 2.415 from muzzle, 25° lead-out angle with R3.00 transition radius.

I mention all of this detail in case someone else wants to see if they get the same results or not.

Unfluted it "weighs" 5.55 lbs and has a surface area of 105.02 square inches.

Fluted it weighs 4.45 lbs and has a surface area of 115.53 square inches.

By my math that is only a 10% gain in surface area. From messing around with these models it is very easy to make that number far lower as these flutes are pretty deep in a barrel contour that is pretty stout.

Next I looked at bending stiffness. I held the tenon fixed and put a 100 lbs downward force on the muzzle.

Unfluted exaggerated deflection diagram:

Fluted exaggerated deflection diagram:

Comparing the two peak deflection numbers the fluted barrel deflected down ~.06" more than did the unfluted barrel. That's roughly 60% more deflection!

I have not had time to perform a reality check on these results. I trust the process, these just aren't quite the numbers that I was expecting to see. Assuming that these results are valid this says that a fluted barrel is NOT stiffer than the same profile unfluted barrel. I was expecting that unfluted would be stiffer, but not by such a large margin.

Did you use the Solidworks default material properties or did you make a custom material property from a source like matweb.com?I have not had time to perform a reality check on these results. I trust the process, these just aren't quite the numbers that I was expecting to see.

ntsqd

Well-Known Member

Used their default for Annealed 4130 steel. Wasn't happy with the annealed aspect, but didn't have time to install something else. It was a quick exercise! That alone is likely some of the unexpected numbers, but I don't think that it is the whole story.Did you use the Solidworks default material properties or did you make a custom material property from a source like matweb.com?

FWIW it is rare that I use that part of SW. I'd love it if someone more familiar with that package repeated my experiment, first with the annealed 4130 and then again with 4130 at some level of HT so that we could see how the difference in HT affects the results.

Mark, I expected that removing material from the OD would reduce the barrel stiffness since you're effectively making the barrel smaller in continuous OD. And I know how the 'I' calculation works, so I shouldn't have been as surprised as I was.

What would be the typical "flex" at the muzzle end of a 300WM during fire, with a barrel diameter like this assuming the tenon end is supported?

I'm assuming less than 100lbs hanging weight would cause?

Is the flute depth .875-.750 divided by 2?

Forgive me I'm learning'

I'm assuming less than 100lbs hanging weight would cause?

Is the flute depth .875-.750 divided by 2?

Forgive me I'm learning'