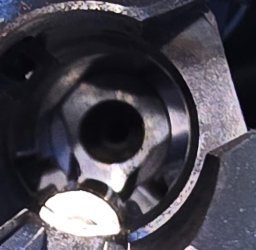

I agree! The simplest fix is to use tipped bullets. I've used 2 rotary mags for 6.5 and my current one is the 308 magazine. You can see where it spearheads into the end of the barrel making a copper mark in this picture. The position the bolt face shoves the live round is too steep. I'll send this box of Hammers back and order the 125 tipped.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ruger American cycling problems

- Thread starter Raudy707

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Oh I agree! They are disposable rifles in my opinion. This was my sons first rifle purchase. I wanted him to go Tikka, but he liked the green mamba color and matte black heavier barrel look. It shoots really good for a $400 rifle. But the finish sucks, it rusts in fog, trigger creeps like a sloth, stock is flimsy and it's never fed ammo without tips! Ha ha!Don't take this the wrong way, but some of those Ruger Americans are garbage. A guy had one threaded from the factory and ended up having a baffle strike with a new can in a local gun shop. You get what you pay for.

It's a shame they haven't fixed the mag issues. These rifles generally shoot well. I'm sure with a little R&D on the follower and feeds lips they could function better.

As for the trigger get a $12 mcarbo spring at 2lbs, helps a lot.

As for the trigger get a $12 mcarbo spring at 2lbs, helps a lot.

I would think that where the barrel threads into the receiver and stops at the face that their shouldn't be any step for the tip of a bullet to hang up on going into the chamber. I've never looked at a Ruger American so I could be wrong.

At the front of were the magazine stops their should be a slight ramp to guide the bullet into the chamber and then just a continuous line of travel with zero step from receiver to barrel chamber. It would help everyone if you could take a picture of where the tip of bullet is catching up on.

At the front of were the magazine stops their should be a slight ramp to guide the bullet into the chamber and then just a continuous line of travel with zero step from receiver to barrel chamber. It would help everyone if you could take a picture of where the tip of bullet is catching up on.

Sorry I didn't see the pictures before my previous comment. To me that is a very how do I say, Inexpensive way to build a rifle. Could you possibly grind the bottom corner at a angle . Maybe just .50 thousands at a 45° angle?

You might try to file or sand material off the feed lips a little bit at a time to get the case to ride higher in the mag. You can use a dremel but a micro file would be better to keep the feed lips uniform and straight. Just a thought

Also do not go deeper than the web base of the cartridge case. Hence the 45° or so. If their is nothing supporting the thin case wall you most likely bulge the case if not blow out the case wall. All very bad things. Just put a small chamfer on the bottom of barrel.

Nimrodmar10

Well-Known Member

Is the bullet tip hitting below the chamber, or above? If it's hitting below, open the feed lips on the magazine. If it's hitting above the chamber bend the feed lips down slightly.

Is the magazine you're using plastic or metal?

Is the magazine you're using plastic or metal?

Similar threads

- Replies

- 87

- Views

- 68K

- Replies

- 38

- Views

- 10K