-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

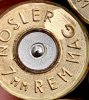

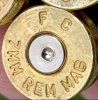

Look at the Difference in Brass Softness!

- Thread starter Ingwe

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

25WSM

Well-Known Member

Can't go by that test. The 2 cases have different internal volume. I agree that Nosler and Norma have softer brass but used at the correct pressure they are fine.

Shep

Shep

Ingwe

Well-Known Member

- Joined

- Jul 3, 2011

- Messages

- 1,041

Can't go by that test. The 2 cases have different internal volume. I agree that Nosler and Norma have softer brass but used at the correct pressure they are fine.

Shep

I'm not insinuating that there is anything wrong with the Nosler brass...I just posted what was a surprising result for me.

I forgot to add that the markings on the Norma brass that I fired was not as pronounced as what you see here on the Nosler, but was more than what I saw on the Federal's

Elk Hunter 338

Official LRH Sponsor

25wsm on this one..

i actually love norma brass and have found it to be my go to in many cartridges

also the surrounding the F on the federal case has a pretty dam good ejector mark also

i actually love norma brass and have found it to be my go to in many cartridges

also the surrounding the F on the federal case has a pretty dam good ejector mark also

In my experience Norma brass is significantly better than Federal. Currently loading for a buddy's 7mm Rem Mag and he has Federal brass. The primer pockets are loose after a few mild loads. My Dad uses Norma brass in his 7mmRM. With the same bullet and powder but 40fps faster, his Norma brass pockets are as tight at 10 firings as they were when new.

25WSM

Well-Known Member

Just saying if you shoot the exact same powder charge in brass with different volumes the one with less volume is going to have more pressure. That's why reloading manuals give you exact components used. I shoot Lapua brass in my Creed and if I used the Hornady load I worked up in my lapua case it's close to blowing a primer and very stiff bolt lift. But a few grains less powder in the lapua is good to go and the same speed. Adg brass is also very heavy and has less capacity.

Shep

Shep

Ingwe

Well-Known Member

- Joined

- Jul 3, 2011

- Messages

- 1,041

That load is about 150 fps too hot for anyones brass.

Besides ejector mark on Nosler brass there are no other signs of pressure....bolt lift is normal and rifle puts 3 rounds into a cluster at 200 yards

MagnumManiac

Well-Known Member

I am just about to dabble in my first 7mm as soon as this CORONA crap dies down.

Have acquired a Rem 700 Sendero II in 7RM.

Of all the brass out there, what do you guys recommend and use?

Is Remington brass ok?

Cheers.

Have acquired a Rem 700 Sendero II in 7RM.

Of all the brass out there, what do you guys recommend and use?

Is Remington brass ok?

Cheers.

bigedp51

Well-Known Member

- Joined

- Dec 10, 2010

- Messages

- 1,022

Brass hardness can vary between brands, and ejector marks and base diameter increase means you are pushing the brass beyond its elastic limits. Reduce the load 1 or 2 grains and you will not see the ejector marks.

Below Lake City brass is harder than Lapua so it makes me wonder what the hardness is on your cases.

X-Ray Spectrometry of Cartridge Brass

X-Ray Spectrometers Reveal Metal Content of Major Cartridge Brass Brands

https://www.accurateshooter.com/technical-articles/x-ray-spectrometry-of-cartridge-brass/

1. The range of Copper/Zinc ratios suitable for use in cartridge making by typical processes is 85/15 to 65/35 (% by weight or mass).

2. The range of Copper/Zinc ratios suitable for use in cartridges intended for reloading is 80/20 to 70/30. Above 80% copper, the resulting case would tend to be too soft and difficult to attain the distribution of hardness desired (harder at the base and softer at the neck). Below 70% copper the resulting case would tend to be too hard, would work harden too quickly and require frequent annealing. [Editor: That said, the 'brown box' 6mmBR Lapua brass, with 62% copper/36% zinc content, enjoys an unrivaled reputation for both accuracy and its ability to perform well after a dozen or more reloading cycles. We know 30BR shooters who have shot the same old-style Lapua brass (6mmBR parent case) more than 50 times. So maybe the "expert" view needs re-thinking.]

3. As the percentage of zinc increases, the tensile strength, yield strength and hardness tend to increase. However, above 35% zinc, while tensile strength will continue to tend to increase, both yield strength and hardness will tend to begin to decrease.

4. The trace additives of iron and/or silicon are used to control the processing characteristics of the alloy. Trace additions of chromium will improve corrosion resistance and give a shinier surface (both largely cosmetic).

5. Selection of the alloy and additives is a trade off among: end use desired properties; processing time and yield; and cost of materials. For example, the classic 70/30 cartridge brass was considered an optimum combination of corrosion resistance and hardness for single use by the military with good process yield at acceptable material cost.

6. All of my responding experts were surprised by the brown box Lapua alloy except for the oldest. He remembered using an almost identical alloy late in WWII when copper was in very short supply for military small arms ammunition.

Below Lake City brass is harder than Lapua so it makes me wonder what the hardness is on your cases.

X-Ray Spectrometry of Cartridge Brass

X-Ray Spectrometers Reveal Metal Content of Major Cartridge Brass Brands

https://www.accurateshooter.com/technical-articles/x-ray-spectrometry-of-cartridge-brass/

1. The range of Copper/Zinc ratios suitable for use in cartridge making by typical processes is 85/15 to 65/35 (% by weight or mass).

2. The range of Copper/Zinc ratios suitable for use in cartridges intended for reloading is 80/20 to 70/30. Above 80% copper, the resulting case would tend to be too soft and difficult to attain the distribution of hardness desired (harder at the base and softer at the neck). Below 70% copper the resulting case would tend to be too hard, would work harden too quickly and require frequent annealing. [Editor: That said, the 'brown box' 6mmBR Lapua brass, with 62% copper/36% zinc content, enjoys an unrivaled reputation for both accuracy and its ability to perform well after a dozen or more reloading cycles. We know 30BR shooters who have shot the same old-style Lapua brass (6mmBR parent case) more than 50 times. So maybe the "expert" view needs re-thinking.]

3. As the percentage of zinc increases, the tensile strength, yield strength and hardness tend to increase. However, above 35% zinc, while tensile strength will continue to tend to increase, both yield strength and hardness will tend to begin to decrease.

4. The trace additives of iron and/or silicon are used to control the processing characteristics of the alloy. Trace additions of chromium will improve corrosion resistance and give a shinier surface (both largely cosmetic).

5. Selection of the alloy and additives is a trade off among: end use desired properties; processing time and yield; and cost of materials. For example, the classic 70/30 cartridge brass was considered an optimum combination of corrosion resistance and hardness for single use by the military with good process yield at acceptable material cost.

6. All of my responding experts were surprised by the brown box Lapua alloy except for the oldest. He remembered using an almost identical alloy late in WWII when copper was in very short supply for military small arms ammunition.

I personally use Norma with good results, for all my .284 cartridges. The only issue I ever had with it was shallow primer pockets on about 50 of 100 cases in a single box for my 280Rem. ADG has 7RM brass too.I am just about to dabble in my first 7mm as soon as this CORONA crap dies down.

Have acquired a Rem 700 Sendero II in 7RM.

Of all the brass out there, what do you guys recommend and use?

Is Remington brass ok?

Cheers.

naja302

Well-Known Member

- Joined

- Jun 28, 2013

- Messages

- 160

I had pressure signs in my 7mm Rem Mag at a much lower speed with Norma Brass...like 2800 FPS VS 3000 with Rem brass. Of course accuracy sucked with the Remington brass so I use the slow load. I understand that the brass volumes are different and therefore loads need to be worked up to separately but I would've thought that by doing so you'd be in the same general velocity range.

snox801

Well-Known Member

As said different capacity in case. Even then you can see the primer is a bit more flat with less showing on brass. So I agree those are a bit to hot.

I look for 3 things. Primer, brass flow, and bolt lift.

mid I see two of either I know I'm two high and back off. Can live with some brass flow or flat primer as they can be different depending on which products you use. Also helps looking for two out of three when using titanium action as you can get a false sense of bolt stick with gulling of ti on ti.

I look for 3 things. Primer, brass flow, and bolt lift.

mid I see two of either I know I'm two high and back off. Can live with some brass flow or flat primer as they can be different depending on which products you use. Also helps looking for two out of three when using titanium action as you can get a false sense of bolt stick with gulling of ti on ti.