I wanted a cartridge to be used primarily for competition, would function with moderate recoil and have efficient performance in windy conditions. My aim was to shoot 168 or greater grain bullets, initially starting with 180 grain Lapua Scenar L. At first, my selection narrowed down to the Winchester 7mm WSM and the Remington 7mm SAUM. Reviews of the Winchester WSM suggested the shorter neck length perhaps less adequate for holding heavy elongated bullets and exhibits a short barrel life. The Remington SAUM had the characteristics of what I was looking for. The issue for the SAUM is a virtual impossibility of finding either headstamp brass or 300 SAUM brass for necking down. That led me to looking at the Wildcats of which the 7mm Sherman ss fit the characteristics of what I was looking for (https://shermanwildcatcartridges.com).

Sherman 7mm SS

The Sherman ss is 0.075" shorter oal than the Remington SAUM. It is 0.095" shorter at the neck shoulder junction. It has a 0.020" longer neck than the Remington SAUM. It has a 40-degree shoulder, less body taper and a 0.331" neck. The shoulder body taper should keep case stretching to a minimum and contain the flame point within the case neck much better than the Remington SAUM or Winchester WSM. The case provides about 1-2 grains more powder capacity than the SAUM. The base on the case will not fit into a standard 308 type bolt face. The 40-degree shoulder may have an impact on feeding from a magazine.

Rifle

The rifle in this case was a Remington 40x single shot chambered in 7.82 Lazzeroni. The bolt face already was big enough for the Sherman. Since the Remington 40x is a single shot, magazine feeding is not an issue.

A Shilen select stainless pre turned match barrel 27 inches long having 1:8 twist with rachet rifling in heavy varmint contour with a muzzle break was purchased and shipped to my gunsmith. According to Sherman Wildcats website reamers are available for the Sherman cartridge, and they are set up for the Berger 180 grain VLD (personal communication with Richard Sherman). A dummy round was provided to the gunsmith for both reaming (which resulted in a COAL of 2.8575 at the lands) and head spacing. After completing the work, a 10-moa steel Picatinny base along with a 6-24x40 B&L target scope was attached using steel Warne rings. .

Components

Brass cases from Sherman Wildcats are available having the 40-degree shoulder. Figs 1-3 show the container the brass was received in, the packaging inside to protect the necks and displaying the shoulder area. The owner of Sherman Wildcats, Rich, is a great person to speak with and is very knowledgeable. Rich also has dies for the case.

All 50 pieces of brass cases were weighed and analyzed along with inside and outside diameters. The brass weights are within +/- 1.0 grain and have a coefficient of variation of 27% which is good. My tolerance is 0.75 gr and I removed 5 pieces of brass from testing and were used for barrel break-in. The diameter of outside necks before resizing was 0.312 with negligible std. dev. and 0.281 for inside diameters and negligible std. dev. I measured neck thickness and 0.14 was consistent with variation occurring in the third decimal place. The closeness of the mean, median and mode for weight indicate a normal distribution. I ran D'Agostino-Pearson p-value and was 0.1956 which is greater than the test value of 0.05 suggesting the data were normally distributed. Overall brass is very good quality.

I weighed all 100 Lapua 180 grain Scenar L bullets and all were +/- 0.1 grains. The bullets length was 1.4915 which is shorter than the popular Berger 180 hybrid which is 1.527 inches long. I used a Sinclair comparator to measure base to ogive and it was (0.771) which is 0.003 (variance of +/- 0.001) longer than the Berger which is 0.768 inches.

I typically use cast bullets for fireforming new cases. In the Lyman handbook RL-7 and N133 are listed as powders for 145 grain cast bullet for a Remington SAUM from 21.0 to 29.5 grains. I used RL-7 recipe with 25.0 grains of powder. I also had a few 150 grain Nosler jacketed bullets available and used those in reduced loads to break in the Shilen barrel.

I also use a L.E. Wilson case trimmer and found that the RSAUM new case holder will not work with the Sherman brass which I assume is because of the 40 degree shoulder. I did find the RSAUM fired case holder works with the Sherman brass and is what was used to trim resized cases.

During a conversation with Rich, he informed me that this cartridge prefers slow burning powders. On the Sherman website there is a pdf reloading data file and RL 26 and N565 were used quite a bit for 180 grain bullets. I did find one reference (https://forum.nosler.com/threads/7mm-saum-quickload-request.43221) that said Quick Load indicated N560 was the ideal powder. Unfortunately, I do not have any N560 in stock.

CCI BR2 primers were used in all testing.

In my situation I have N565, (N568 which I use in my 300 PRC along with N570), RL-19, IMR 7977, IMR 7828, RL-23 and RL 26 powders. Of those powders RL-23, RL 26 and N570 I had the least of and were dropped from testing. According to several articles N565 is close to H1000 in burn rate and on the Hodgdon web site they list 65.5 grains as a max for 175 grain bullets. I filled a Sherman case to 63 grains which came to the bottom of the neck which is very close to the QL data (https://forum.nosler.com/threads/7mm-saum-quickload-request.43221). I also used a drop tube, and it made the level move down near the bottom of the shoulder junction. Nosler provided a load for RL-19 and Sierra/Hodgdon for IMR 7977 and 7828 for the Remington SAUM. I started with N565 and RL 19 which I had the most in stock.

Powder Evaluation:

One program that is used for powder evaluation is Quick Load (https://www.neconos.com/quickload-ballistic-prediction-software/). There is another program on the market called GRT (https://grtools.de/doku.php). I was able to download this program and use it in my powder assessment. The two programs use different algorithms for determining powder influence on pressure/velocity. First thing was to open the cartridge designer module in GRT and select the Remington 7mm SAUM as a starting point. I then used the cartridge designer to change the case dimensions for the Sherman ss case and saved it to the caliber database.

I did find one comprehensive assessment with QL for the SAUM using the Berger 180 gr VLD bullet ( https://forum.nosler.com/threads/7mm-saum-quickload-request.43221) and N568 powder. I reproduced the input data for GRT and was able to come up with very similar results. For example, QL predicted 64.6 gr N568 first near maximum load and GRT predicted the same. QL overpressure value was 67.2 and GRT was 66.6 which are very close. For 64 grains N568 QL predicted 2793 fps and GRT 2776 fps, again very close. However, GRT indicated that the burn rate in the barrel was 84% for N568 which does lend itself to probably being a good powder for this cartridge (I look for near 100 or 100% burn rate).

At this point I felt confident to start an evaluation with GRT for the Sherman using RL 19, N565, IMR 7977 and IMR 7828. I did find one issue, the output from GRT for Excel seemed not to work in my Excel (365 version) but the JASON format did. Importing a JASON file into Excel is a multistep process but was able to output desired results.

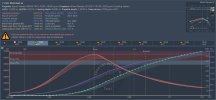

Results for IMR 7977, IMR 7828 and RL 19 were very close to the reported data for these powders. Results for N565 Table 1. An example of the data in graphic form for RL 26 is illustrated in Fig 4. The burn rate at the end of the barrel was 100% for N565 and RL 19 powders.

Testing: I did find one article that indicated an accuracy node is somewhere near 0.97 of the maximum velocity. Results for two powders N565 and RL 19, were promising providing initially a 0.7 (center-to-center) inch groups which was then retested varying the charge plus/- 0.2 and for 56.0 grains of RL 19 a 0.5 inch group was developed. For N565 a charge of 60.0 grains provided a 0.5 inch group. Initial COAL was 2.8475 which is 0.01 off the lands. Then tried seating depth at 0.01 in the lands 2.8670 COAL and at the lands 2.8575 COAL with the 2.8575 COAL producing a 0.35 inch groups (Figs 5,6) . Resulting velocities for N565 were 2924 sd 6 and for RL 19 2880 sd 8 fps.

I then ran one test with RL 26 and IMR 7828 ssc and was able to obtain 0.7 inch groups. Those could be developed further once powder supplies return. I took the N565 load and tested it on the farthest distance at our range which is 600 yards. Rifle was set on Sinclair F-Class front rest and leaf bag rear rest. Krestel 5700 Elite ballistics unit along with Kestrel Android shooting solution was used – conditions were near perfect 2mph wind, temp 55, humidity 35%, pressure 30.42 and elevation 810 feet. The results are show in Fig. 7 – they are distorted because of having to shrink the image down quite a bit to fit into an acceptable figure. I feel like my goals were accomplished.

I use Lapua bullets in most of my rifles and they all seem to like to be seated near or slightly in the lands. In this case at the lands.

The 7mm Sherman ss was not difficult to tune. I would offer that the rile/barrel combination matches well to the 180 Scenar L bullet.

Sherman 7mm SS

The Sherman ss is 0.075" shorter oal than the Remington SAUM. It is 0.095" shorter at the neck shoulder junction. It has a 0.020" longer neck than the Remington SAUM. It has a 40-degree shoulder, less body taper and a 0.331" neck. The shoulder body taper should keep case stretching to a minimum and contain the flame point within the case neck much better than the Remington SAUM or Winchester WSM. The case provides about 1-2 grains more powder capacity than the SAUM. The base on the case will not fit into a standard 308 type bolt face. The 40-degree shoulder may have an impact on feeding from a magazine.

Rifle

The rifle in this case was a Remington 40x single shot chambered in 7.82 Lazzeroni. The bolt face already was big enough for the Sherman. Since the Remington 40x is a single shot, magazine feeding is not an issue.

A Shilen select stainless pre turned match barrel 27 inches long having 1:8 twist with rachet rifling in heavy varmint contour with a muzzle break was purchased and shipped to my gunsmith. According to Sherman Wildcats website reamers are available for the Sherman cartridge, and they are set up for the Berger 180 grain VLD (personal communication with Richard Sherman). A dummy round was provided to the gunsmith for both reaming (which resulted in a COAL of 2.8575 at the lands) and head spacing. After completing the work, a 10-moa steel Picatinny base along with a 6-24x40 B&L target scope was attached using steel Warne rings. .

Components

Brass cases from Sherman Wildcats are available having the 40-degree shoulder. Figs 1-3 show the container the brass was received in, the packaging inside to protect the necks and displaying the shoulder area. The owner of Sherman Wildcats, Rich, is a great person to speak with and is very knowledgeable. Rich also has dies for the case.

All 50 pieces of brass cases were weighed and analyzed along with inside and outside diameters. The brass weights are within +/- 1.0 grain and have a coefficient of variation of 27% which is good. My tolerance is 0.75 gr and I removed 5 pieces of brass from testing and were used for barrel break-in. The diameter of outside necks before resizing was 0.312 with negligible std. dev. and 0.281 for inside diameters and negligible std. dev. I measured neck thickness and 0.14 was consistent with variation occurring in the third decimal place. The closeness of the mean, median and mode for weight indicate a normal distribution. I ran D'Agostino-Pearson p-value and was 0.1956 which is greater than the test value of 0.05 suggesting the data were normally distributed. Overall brass is very good quality.

I weighed all 100 Lapua 180 grain Scenar L bullets and all were +/- 0.1 grains. The bullets length was 1.4915 which is shorter than the popular Berger 180 hybrid which is 1.527 inches long. I used a Sinclair comparator to measure base to ogive and it was (0.771) which is 0.003 (variance of +/- 0.001) longer than the Berger which is 0.768 inches.

I typically use cast bullets for fireforming new cases. In the Lyman handbook RL-7 and N133 are listed as powders for 145 grain cast bullet for a Remington SAUM from 21.0 to 29.5 grains. I used RL-7 recipe with 25.0 grains of powder. I also had a few 150 grain Nosler jacketed bullets available and used those in reduced loads to break in the Shilen barrel.

I also use a L.E. Wilson case trimmer and found that the RSAUM new case holder will not work with the Sherman brass which I assume is because of the 40 degree shoulder. I did find the RSAUM fired case holder works with the Sherman brass and is what was used to trim resized cases.

During a conversation with Rich, he informed me that this cartridge prefers slow burning powders. On the Sherman website there is a pdf reloading data file and RL 26 and N565 were used quite a bit for 180 grain bullets. I did find one reference (https://forum.nosler.com/threads/7mm-saum-quickload-request.43221) that said Quick Load indicated N560 was the ideal powder. Unfortunately, I do not have any N560 in stock.

CCI BR2 primers were used in all testing.

In my situation I have N565, (N568 which I use in my 300 PRC along with N570), RL-19, IMR 7977, IMR 7828, RL-23 and RL 26 powders. Of those powders RL-23, RL 26 and N570 I had the least of and were dropped from testing. According to several articles N565 is close to H1000 in burn rate and on the Hodgdon web site they list 65.5 grains as a max for 175 grain bullets. I filled a Sherman case to 63 grains which came to the bottom of the neck which is very close to the QL data (https://forum.nosler.com/threads/7mm-saum-quickload-request.43221). I also used a drop tube, and it made the level move down near the bottom of the shoulder junction. Nosler provided a load for RL-19 and Sierra/Hodgdon for IMR 7977 and 7828 for the Remington SAUM. I started with N565 and RL 19 which I had the most in stock.

Powder Evaluation:

One program that is used for powder evaluation is Quick Load (https://www.neconos.com/quickload-ballistic-prediction-software/). There is another program on the market called GRT (https://grtools.de/doku.php). I was able to download this program and use it in my powder assessment. The two programs use different algorithms for determining powder influence on pressure/velocity. First thing was to open the cartridge designer module in GRT and select the Remington 7mm SAUM as a starting point. I then used the cartridge designer to change the case dimensions for the Sherman ss case and saved it to the caliber database.

I did find one comprehensive assessment with QL for the SAUM using the Berger 180 gr VLD bullet ( https://forum.nosler.com/threads/7mm-saum-quickload-request.43221) and N568 powder. I reproduced the input data for GRT and was able to come up with very similar results. For example, QL predicted 64.6 gr N568 first near maximum load and GRT predicted the same. QL overpressure value was 67.2 and GRT was 66.6 which are very close. For 64 grains N568 QL predicted 2793 fps and GRT 2776 fps, again very close. However, GRT indicated that the burn rate in the barrel was 84% for N568 which does lend itself to probably being a good powder for this cartridge (I look for near 100 or 100% burn rate).

At this point I felt confident to start an evaluation with GRT for the Sherman using RL 19, N565, IMR 7977 and IMR 7828. I did find one issue, the output from GRT for Excel seemed not to work in my Excel (365 version) but the JASON format did. Importing a JASON file into Excel is a multistep process but was able to output desired results.

Results for IMR 7977, IMR 7828 and RL 19 were very close to the reported data for these powders. Results for N565 Table 1. An example of the data in graphic form for RL 26 is illustrated in Fig 4. The burn rate at the end of the barrel was 100% for N565 and RL 19 powders.

Testing: I did find one article that indicated an accuracy node is somewhere near 0.97 of the maximum velocity. Results for two powders N565 and RL 19, were promising providing initially a 0.7 (center-to-center) inch groups which was then retested varying the charge plus/- 0.2 and for 56.0 grains of RL 19 a 0.5 inch group was developed. For N565 a charge of 60.0 grains provided a 0.5 inch group. Initial COAL was 2.8475 which is 0.01 off the lands. Then tried seating depth at 0.01 in the lands 2.8670 COAL and at the lands 2.8575 COAL with the 2.8575 COAL producing a 0.35 inch groups (Figs 5,6) . Resulting velocities for N565 were 2924 sd 6 and for RL 19 2880 sd 8 fps.

I then ran one test with RL 26 and IMR 7828 ssc and was able to obtain 0.7 inch groups. Those could be developed further once powder supplies return. I took the N565 load and tested it on the farthest distance at our range which is 600 yards. Rifle was set on Sinclair F-Class front rest and leaf bag rear rest. Krestel 5700 Elite ballistics unit along with Kestrel Android shooting solution was used – conditions were near perfect 2mph wind, temp 55, humidity 35%, pressure 30.42 and elevation 810 feet. The results are show in Fig. 7 – they are distorted because of having to shrink the image down quite a bit to fit into an acceptable figure. I feel like my goals were accomplished.

I use Lapua bullets in most of my rifles and they all seem to like to be seated near or slightly in the lands. In this case at the lands.

The 7mm Sherman ss was not difficult to tune. I would offer that the rile/barrel combination matches well to the 180 Scenar L bullet.

Attachments

-

Fig 1 packaging.jpg254.6 KB · Views: 52

Fig 1 packaging.jpg254.6 KB · Views: 52 -

Fig 2 Storage case.jpg306.4 KB · Views: 50

Fig 2 Storage case.jpg306.4 KB · Views: 50 -

Fig 3 7mm ss brass.jpg29.1 KB · Views: 48

Fig 3 7mm ss brass.jpg29.1 KB · Views: 48 -

Fig 4 Grphic View RL 26.jpg109.7 KB · Views: 56

Fig 4 Grphic View RL 26.jpg109.7 KB · Views: 56 -

Fig 5 4 shot group N565 COAL 2.8575.jpg341.9 KB · Views: 55

Fig 5 4 shot group N565 COAL 2.8575.jpg341.9 KB · Views: 55 -

Fig 6 4 shot group RL 19 COAL 2.8575.jpg548 KB · Views: 66

Fig 6 4 shot group RL 19 COAL 2.8575.jpg548 KB · Views: 66 -

Fig 7 600 yard test.jpg28.7 KB · Views: 70

Fig 7 600 yard test.jpg28.7 KB · Views: 70 -

Table 1 N565 Simulation.txt1.5 KB · Views: 83