oregonreloader

Well-Known Member

- Joined

- Oct 3, 2013

- Messages

- 52

Fairly Lengthy B.MAG Shooting Report

After a 3-month weather delay, I finally got around to shooting my B.MAG with both 20gn and 25gn ammo. A summary report is provided below and covers two range sessions. The first session was done using the B.MAG exactly as I received it from Savage. (Reading the threads above, you'll know that this was the 2nd B.MAG I'd had, maybe the 3rd, depending on how you count. The first B.MAG was replaced by Savage because it didn't group. The second one didn't group either and I had a lot of problems with it, so Savage took it back, said they'd fixed it and returned it to me in late December, so that might count as B.MAG #3.) I did add the Leupold Vari-X III I'd used before.

On Sunday, March 16, the weather had warmed sufficiently to warrant some accuracy testing with the B.MAG. The altitude at the range is about 4,000' and the temperature was about 55-deg F, with a 5-8mph quartering headwind wind from the left. I shot both the 25gn and the 20gn cartridges. After sighting it in, the 25gn gave me a 100-yd group size of about 2¼" and the 20gn gave a group size of about 2½" at the same distance. I tried chronographing the loads but my CED M2 couldn't see the bullets.

I still had the "gritty trigger", the "bolt falls out" and the "magazine hard to load" problems I've described previously. So I'm not sure what Savage did, other than replace the stock. But the real problem was that, while the replacement stock allowed the barrel to 'float' when I'd received it back from Savage in late December, the barrel did NOT float in March. Simply sitting upright in the corner, the stock must've cold-flowed back to contact the barrel. [This might explain why Savage maintains that it's a floating barrel (when they ship it) but when we buy it, it doesn't float. Maybe the composite stock hadn't fully cured when they assembled the rifle for shipping, and it cold flows to contact the barrel with time...?]

Problems, yes, but even worse, a good percentage of the 20gn ammo failed to extract. I had to use a cleaning rod jammed in from the muzzle to free the case from the chamber. The rifle was clean so I'm a bit mystified about why the failure-to-extract. The cartridges that failed to extract showed a 'larger-than-the-others' radius of curvature where the forward side of the rim joins the body of the cartridge. That might allow the extractor to simply ride up and over the rim without 'grabbing' it for extraction(?) I contacted Winchester and I've sent them some unfired rounds and two of the expended brass, all from the same box, for their assessment.

I needed to address the non-floating barrel issue, but I didn't want to whack away on the already-flimsy forend. So, last night (Saturday, 3/22) I inserted a screwdriver between the barrel and the forend to force the forend away from the barrel and used a 2000W heat gun and heated the forend region to 170-deg F and let it cool and removed the screwdriver. The barrel now floated.

Today, 3/23, I shot again. The temperature was in the mid-50s and the wind was about the same as last time (see above). Before shooting, I checked the forend-to-barrel clearance. Gads! It had decreased the clearance so that a dollar bill would just barely slip past the one hang-up it had before. Better than before, though, so I figured I'd go ahead and shoot. All the data described below was shot at 100-yds, with 8" targets.

I started with the 25gn ammo. For the first 5 shots, I let the barrel rest on the Lead Sled forend support pad--just to see what I'd get. What I got was about a 9" group. Terrible. Don't do that. I've got a photo of the group but I'll not post it unless someone wants to see it.

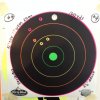

For the next five, I rested the forend on the Lead Sled forward pad. I got a good group of about 1½". I adjusted the elevation on the scope and fired 5 more rounds at the same target and got another 1½" group, as shown in the photo marked #2, below.

I then shot 5 shots at another 100-yd target, as shown in photo marked #3 below--another good group.

I then switched to the 20gn ammo and shot 5 rounds without adjusting the scope. The group was about 2½", as shown in the photo marked #4, below, and 2 of the five failed to extract.

To figure out whether it was the "indian or the arrow", I switched to my Savage 917V in .17HMR--a rifle that does a good job for me on ground squirrels. I used the Hornady 17gn ballistic tip ammo. I hadn't fired this rifle for nearly a year. The group I shot was just over 1½" and is shown in the photo marked #5, below. The flyer shown in the HMR photo was the first shot of the five and I attribute it to being the first shot and the trigger feel was distinctly different than the B.MAG's. Note also that for the B.MAG, I was using the 20x setting on the Leupold, but only 9x was available for the Simmons on the HMR. This might explain the somewhat larger group.

I conclude from these two shooting sessions that: 1) the 25gn ammo is more accurate than the 20gn (in my rifle, your mileage may differ), 2) relieving the pressure of the forend on the barrel improved accuracy, and 3) the 17HMR is still a good shooter. Not described above was that I was shooting the 3/23 data in a single-shot mode. I had tried to fix the 'hard-to-load" magazine and when I took it apart, I could never re-assemble it. Don't do that, either! (I've ordered two magazines from Savage.) And, I found, when the bolt is operated slowly, it does not fall out when ejecting a cartridge.

I was about to dump the B.MAG but today's session said to me, "...hummm...let's keep it for at least another session." I think the next effort will be to heat the forend just forward of the magazine bay--maybe to around 200deg--and attempt to open up the gap to completely float the barrel. And my gunsmith tells me he can probably smooth the trigger feel. Next weekend awaits, weather permitting. (But that 25gn ammo is very hard to get. 17HMR is plentiful.)

After a 3-month weather delay, I finally got around to shooting my B.MAG with both 20gn and 25gn ammo. A summary report is provided below and covers two range sessions. The first session was done using the B.MAG exactly as I received it from Savage. (Reading the threads above, you'll know that this was the 2nd B.MAG I'd had, maybe the 3rd, depending on how you count. The first B.MAG was replaced by Savage because it didn't group. The second one didn't group either and I had a lot of problems with it, so Savage took it back, said they'd fixed it and returned it to me in late December, so that might count as B.MAG #3.) I did add the Leupold Vari-X III I'd used before.

On Sunday, March 16, the weather had warmed sufficiently to warrant some accuracy testing with the B.MAG. The altitude at the range is about 4,000' and the temperature was about 55-deg F, with a 5-8mph quartering headwind wind from the left. I shot both the 25gn and the 20gn cartridges. After sighting it in, the 25gn gave me a 100-yd group size of about 2¼" and the 20gn gave a group size of about 2½" at the same distance. I tried chronographing the loads but my CED M2 couldn't see the bullets.

I still had the "gritty trigger", the "bolt falls out" and the "magazine hard to load" problems I've described previously. So I'm not sure what Savage did, other than replace the stock. But the real problem was that, while the replacement stock allowed the barrel to 'float' when I'd received it back from Savage in late December, the barrel did NOT float in March. Simply sitting upright in the corner, the stock must've cold-flowed back to contact the barrel. [This might explain why Savage maintains that it's a floating barrel (when they ship it) but when we buy it, it doesn't float. Maybe the composite stock hadn't fully cured when they assembled the rifle for shipping, and it cold flows to contact the barrel with time...?]

Problems, yes, but even worse, a good percentage of the 20gn ammo failed to extract. I had to use a cleaning rod jammed in from the muzzle to free the case from the chamber. The rifle was clean so I'm a bit mystified about why the failure-to-extract. The cartridges that failed to extract showed a 'larger-than-the-others' radius of curvature where the forward side of the rim joins the body of the cartridge. That might allow the extractor to simply ride up and over the rim without 'grabbing' it for extraction(?) I contacted Winchester and I've sent them some unfired rounds and two of the expended brass, all from the same box, for their assessment.

I needed to address the non-floating barrel issue, but I didn't want to whack away on the already-flimsy forend. So, last night (Saturday, 3/22) I inserted a screwdriver between the barrel and the forend to force the forend away from the barrel and used a 2000W heat gun and heated the forend region to 170-deg F and let it cool and removed the screwdriver. The barrel now floated.

Today, 3/23, I shot again. The temperature was in the mid-50s and the wind was about the same as last time (see above). Before shooting, I checked the forend-to-barrel clearance. Gads! It had decreased the clearance so that a dollar bill would just barely slip past the one hang-up it had before. Better than before, though, so I figured I'd go ahead and shoot. All the data described below was shot at 100-yds, with 8" targets.

I started with the 25gn ammo. For the first 5 shots, I let the barrel rest on the Lead Sled forend support pad--just to see what I'd get. What I got was about a 9" group. Terrible. Don't do that. I've got a photo of the group but I'll not post it unless someone wants to see it.

For the next five, I rested the forend on the Lead Sled forward pad. I got a good group of about 1½". I adjusted the elevation on the scope and fired 5 more rounds at the same target and got another 1½" group, as shown in the photo marked #2, below.

I then shot 5 shots at another 100-yd target, as shown in photo marked #3 below--another good group.

I then switched to the 20gn ammo and shot 5 rounds without adjusting the scope. The group was about 2½", as shown in the photo marked #4, below, and 2 of the five failed to extract.

To figure out whether it was the "indian or the arrow", I switched to my Savage 917V in .17HMR--a rifle that does a good job for me on ground squirrels. I used the Hornady 17gn ballistic tip ammo. I hadn't fired this rifle for nearly a year. The group I shot was just over 1½" and is shown in the photo marked #5, below. The flyer shown in the HMR photo was the first shot of the five and I attribute it to being the first shot and the trigger feel was distinctly different than the B.MAG's. Note also that for the B.MAG, I was using the 20x setting on the Leupold, but only 9x was available for the Simmons on the HMR. This might explain the somewhat larger group.

I conclude from these two shooting sessions that: 1) the 25gn ammo is more accurate than the 20gn (in my rifle, your mileage may differ), 2) relieving the pressure of the forend on the barrel improved accuracy, and 3) the 17HMR is still a good shooter. Not described above was that I was shooting the 3/23 data in a single-shot mode. I had tried to fix the 'hard-to-load" magazine and when I took it apart, I could never re-assemble it. Don't do that, either! (I've ordered two magazines from Savage.) And, I found, when the bolt is operated slowly, it does not fall out when ejecting a cartridge.

I was about to dump the B.MAG but today's session said to me, "...hummm...let's keep it for at least another session." I think the next effort will be to heat the forend just forward of the magazine bay--maybe to around 200deg--and attempt to open up the gap to completely float the barrel. And my gunsmith tells me he can probably smooth the trigger feel. Next weekend awaits, weather permitting. (But that 25gn ammo is very hard to get. 17HMR is plentiful.)