Huntoregon:

You are heading down a rabbit hole. Dealing with so called "neck tension" can be three things; waste of time, can improve consistency (notice I didn't say accuracy), it can get expensive and frustrating.

All the options posted above are great and I would like to expand on them a bit with some questions. Then share my thoughts and process I've learned after 50+ years loading.

First, what rifle do you have, is it a factory chamber? What brass are you using? And prob the most important question is do you anneal?

Trying to adjust neck tension (inside neck diameter) is a moot point if you don't know the neck ID of your chamber, not using quality brass, and not annealing.

If you are not using quality brass typically neck wall thickness is not consistent, you will never get consistent neck tension from one case to the next.

Brass hardens with each firing, if you don't anneal, a case that has been fired 3 times will have less spring back than a case that has been fired 6 times. I have never figured out a way to keep a lot of brass separated by the number of firings. When you size those to cases with the same bushing or expand with a mandrel, the net result will be different IDs with each case do to the spring back of the brass.

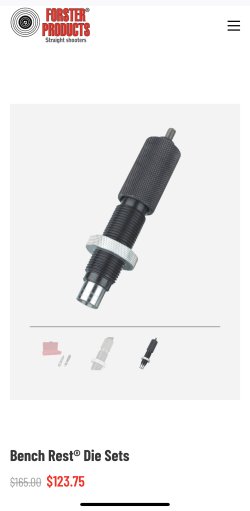

Let's start with bushing dies. A bushing die allows you to change the neck bushing to different sizes to adjust the neck diameter to desired size. I keep on my bench Redding cases for each caliber with different size bushings.

https://www.midwayusa.com/product/1012586433?pid=665599

Each brand of brass has different neck thicknesses, so a bushing you use with Lapua Brass will not be the same one needed for Peterson brass to get the same inside neck diameter.

Mandrel die. Unless you buy multiply precision mandrels, you still are not "adjusting" the so called neck tension. All you are doing is sizing the neck with the FL or neck Die without the expander ball, then expanding it back out with the mandrel. Same process, just now doing it in two steps.

Using a quality bushing die with the correct size bushing, in conjunction with a expanding mandrel about the only thing you gain is less work hardening of the brass unless you get lucky and find the right combo.

The other option is a Collet type die like Lee makes. This is a great option. I personally don't use them, but know plenty that do with great results. For a factory hunting rifle and occasional LR target work, that is prob all you will ever need.

I follow this guy, he really dives into neck tension in the following video, watch it, he is a wealth of knowledge for LR shooting.

The following is how I load and deal with neck tension. All this is just the way I do it, not saying it is the right way, just how I do it.

Cases are always cleaned, then annealed without exception every firing. Then I choose a bushing for my Redding or Custom die that is between .003" to .005" smaller than desired outside diameter of finished round. Then using a mandrel, the necks are opened back up .002 to .003". The the goal is to get a .002" to .003" grip on the bullet.

Once you have worked up a load, you can go back and change "tension" with different size mandrels. In a hunting rifle, you will prob never see the difference. But I have seen changing the ID of a neck by .001" will change the way a match rifle will shoot. What works for one cartridge rifle combo may not work on the next. I have two different F Class rifles chambered in 6mmDasher, both have the same barrels, chambered by the same smith at the same time with the same reamer, they like different neck tensions. Go figure.

With all that is said above and by others, if you are not using top notch components, equipment, with good shooting techniques, you will never see the benefit.

JMHO

Randy

PM sent