The question is "why". This is an area that is known to cause problems with production firearms and ammunition. Why continue to do it the same way as a century ago when it can be easily prevented.2) Your observation of .004" case to chamber crush fit at the HS dimension is correct, not sure what the question was.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question: Reamer Dimensions vs Chamber Dimensions vs Case Dimensions

- Thread starter Batsin

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Wow!Yes, agree. Generally we have no control over how things are made. We may have to "correct" some discrepancy when we buy something.

The gunsmith was telling me I was loading them wrong (he himself did not reload) and when I showed him the necks of 2 different brass vs. the chamber, he wouldn't accept the evidence. It was simple arithmetic. It was never a "no turn" situation here. He told me I couldn't shoot a solid mono bullet because it was "impossible" to function like a cup and core (obturation).

Haven't found my new smith yet.

Because manufacturers making thousands of times more rifles per year than a good gunsmith could ever turn out, and selling them for less than the price of a cut rifled barrel, cannot continue to do so if the tolerances are tightened up. The same holds for brass companies selling brass for 1/2 the price of Lapua or less, which is barely more than the cost of the raw materials. In a bolt action with strong camming action it's a minor problem that rarely occurs. There are budget buyers, and there are quality buyers. If you don't like the fit of brass in your chamber, change manufacturers of your firearm or brass.The question is "why". This is an area that is known to cause problems with production firearms and ammunition. Why continue to do it the same way as a century ago when it can be easily prevented.

Nothing about SAAMI specs is prevent Geissele, Cooper, Kimber, or even Mossberg from making a quality product. SAAMI tolerances are a bare minimum. If someone is turning out a product that you're displeased with, then don't buy it.

Last edited:

Mike Matteson

Well-Known Member

Buy your own reamers and have the barrels re-chamber or chambe a new barrel. years have gone by and I had other smiths turnout rifles for me. A couple a years ago i changed and have a reamer built of me. $250 or so isn't out of line to one and you have the reamer for a very long time.. It's my understand the reamer needs to be reworked after 5 or 6 chamber jobs with. I wish I had done this a long time ago. That way it's set as you want it. Which I reduce the I.D. in the neck area, because I cut my necks on the brass to a thinner thickness. Don't get me wrong I am no gunsmith. Been a carpenter by trade, and dealing with 1/16" or a little less, is as close as I get. At the same time being accurate is still required. Dealing with .001-4" or less is the firearms game. I have a friend that deals in .0001" and less. There isn't a free country jet built that he doesn't have a part in.Because manufacturers making thousands of times more rifles per year than a good gunsmith could ever turn out, and selling them for less than the price of a cut rifled barrel, cannot continue to do so if the tolerances are tightened up. The same holds for brass companies selling brass for 1/2 the price of Lapua or less, which is barely more than the cost of the raw materials. In a bolt action with strong camming action it's a minor problem that rarely occurs. There are budget buyers, and there are quality buyers. If you don't like the fit of brass in your chamber, change manufacturers of your firearm or brass.

Nothing about SAAMI specs is prevent Geissele, Cooper, Kimber, or even Mossberg from making a quality product. SAAMI tolerances are a bare minimum. If someone is turning out a product that you're displeased with, then don't buy it.

I 100% agree. That's my point. We don't need SAAMI to change their tolerances. Their tolerances define the bare minimum. If you want something better you have options ranging from buying a different brand to going full custom. If you buy a $200 AR upper or a $450 bolt action rifle and find ammo that doesn't work flawlessly in it, that doesn't indicate the SAAMI needs to revisit anything. You get what you pay for, and there's a market for budget firearms and ammunition just like there's a market for the high end.Buy your own reamers and have the barrels re-chamber or chambe a new barrel. years have gone by and I had other smiths turnout rifles for me. A couple a years ago i changed and have a reamer built of me. $250 or so isn't out of line to one and you have the reamer for a very long time.. It's my understand the reamer needs to be reworked after 5 or 6 chamber jobs with. I wish I had done this a long time ago. That way it's set as you want it. Which I reduce the I.D. in the neck area, because I cut my necks on the brass to a thinner thickness. Don't get me wrong I am no gunsmith. Been a carpenter by trade, and dealing with 1/16" or a little less, is as close as I get. At the same time being accurate is still required. Dealing with .001-4" or less is the firearms game. I have a friend that deals in .0001" and less. There isn't a free country jet built that he doesn't have a part in.

It's unusual for me to own a rifle with a factory chamber. Some of my reamers are custom spec'd and some are simply SAAMI spec reamers, but the chamber job was done properly and carefully, and both have their advantages and disadvantages.

I just don't see any point is lobbying SAAMI to change anything. The budget market has its place just as much as high end production, semi-custom and custom. The best that can be had is out there if you wanna pay for it. Changing SAAMI specs won't change that, or bring up the quality to price ratio. It will just cause the low end of the budget market not to exist anymore. And actually, modern equipment is making precision cheaper, it just hasn't caught up completely yet. SAMMI isn't needed to fix that issue either.

Last edited:

It is not a matter of changing tolerances. It is a simple matter of eliminating overlap. The specs and tolerances are written on each drawing and are different for each individual cartridge. It turns out that this was done for the .30 Remington and its family as far back as 1905 to prevent the very same issues. Those cartridges were designed for the Remington Autoloading Rifle (later, the Model 8) and someone had the foresight to notice the potential problem. It seems that someone at SAAMI just forgot their own history. Heck, I had to chase down a copy of a 1992 SAAMI publication to even find the 30 Rem drawing.

Edited to add: I did not know this when this thread was started. It occurred to me to look at the 30 Rem when I was looking into early auto-loading rifles.

Edited to add: I did not know this when this thread was started. It occurred to me to look at the 30 Rem when I was looking into early auto-loading rifles.

Last edited:

Yes, but the overlap is perfectly acceptable in a number of actions, and is never dangerous to the user(okay I'm excluding self defense/LEO/military use because that's a different, albeit related issue). Excess space on the other hand is dangerous to the user, so if the company that spec'd the cartridge wants a .010" maximum tolerance between the ammo and chamber, and sets that at -.004" to +.006 because they think it's safe and functional, that's their decision. The company that brings out the cartridge is the company that submits the specs to SAAMI. The same company is usually the one who designs the initial firearms the cartridge is used in. Obviously the specs didn't bother Remington, and anyone designing a rifle based on the cartridge subsequently should know the AMMO spec, and design their rifle to function with any ammunition within the spec. It's quite simple, and it's not SAAMI's responsibility. A manufacturer can use any tolerance they desire, and if you don't like the results, you shouldn't buy from them.It is not a matter of changing tolerances. It is a simple matter of eliminating overlap. The specs and tolerances are written on each drawing and are different for each individual cartridge. It turns out that this was done for the .30 Remington and its family as far back as 1905 to prevent the very same issues. Those cartridges were designed for the Remington Autoloading Rifle (later, the Model 8) and someone had the foresight to notice the potential problem. It seems that someone at SAAMI just forgot their own history. Heck, I had to chase down a copy of a 1992 SAAMI publication to even find the 30 Rem drawing.

Edited to add: I did not know this when this thread was started. It occurred to me to look at the 30 Rem when I was looking into early auto-loading rifles.

SAAMI does not publish guidelines for a rifle manufacturer to follow and guarantee functionality. They publish dimensions and tolerances that the submitting manufacturer chooses. The primary reason is so that OTHER manufacturers CAN make products that function with in-spec ammo or with WELL DESIGNED in-spec firearms. All of the required information is there, and there is no need to change the published specs that you have mention. Any AR manufacture can make sure that their AR functions properly with any in-spec ammo. It's up to the rifle manufacturer to design and build a product that works. It's THAT simple. The manufacturer knows the ammo tolerance, and can easily make rifles that either have a chamber that accepts the ammo easily, or has a loading system that can deal with .004" crush. If they don't like it, it's their problem. Not SAAMI's, and not Remington's.

Any AR manufacturer can simply spec their chamber to be longer than the SAAMI minimum, and equal to the SAAMI maximum and the problem is solved. If a company isn't doing that, and their products have problems, it's the company that is at fault, not SAAMI.

Last edited:

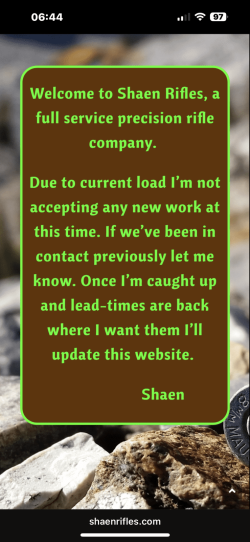

Get ahold of Shaen (pronounced Shane)Yes, agree. Generally we have no control over how things are made. We may have to "correct" some discrepancy when we buy something.

The gunsmith was telling me I was loading them wrong (he himself did not reload) and when I showed him the necks of 2 different brass vs. the chamber, he wouldn't accept the evidence. It was simple arithmetic. It was never a "no turn" situation here. He told me I couldn't shoot a solid mono bullet because it was "impossible" to function like a cup and core (obturation).

Haven't found my new smith yet.

Maegan. He builds tack drivers.

Mike Matteson

Well-Known Member

Generally over several years, when I purchase a rifle, I have in mind to change out the barrel at the start. Even if it's a new rifle. More so for the action, and that's about it. I generally hand load my ammo except 5.56, and it's a m-4 type. There isn't a caliber thatI can't reload for. I don't use it, it just put away for a rainy day. I like my rifles to have at least a 26" barrel or more. Now I have them threaded for a suppressor or muzzle break.I 100% agree. That's my point. We don't need SAAMI to change their tolerances. Their tolerances define the bare minimum. If you want something better you have options ranging from buying a different brand to going full custom. If you buy a $200 AR upper or a $450 bolt action rifle and find ammo that doesn't work flawlessly in it, that doesn't indicate the SAAMI needs to revisit anything. You get what you pay for, and there's a market for budget firearms and ammunition just like there's a market for the high end.

It's unusual for me to own a rifle with a factory chamber. Some of my reamers are custom spec'd and some are simply SAAMI spec reamers, but the chamber job was done properly and carefully, and both have their advantages and disadvantages.

I just don't see any point is lobbying SAAMI to change anything. The budget market has its place just as much as high end production, semi-custom and custom. The best that can be had is out there if you wanna pay for it. Changing SAAMI specs won't change that, or bring up the quality to price ratio. It will just cause the low end of the budget market not to exist anymore. And actually, modern equipment is making precision cheaper, it just hasn't caught up completely yet. SAMMI isn't needed to fix that issue either.

I haven't found where I need a custom action either. I don't shoot match, and generally do quite well in getting my rifles to group. I have even gotten to having a 2nd rifle action and barrels to fireform my brass on.

What does concerns me is the jump or free bore with the copper bullets. I don't have much info. It seem to me the copper bullets like the jump. The longer bullets seem to require more room to allow for the jump. The action part isn't the problem. I never like the WBY mag, because of the free bore in it. I have shot a few of them, but it seem to me they didn't group that good. Never reloaded for one. I do have several belted mag and do just fine with the grouping with them.

Not having much experience with free bore or needs for longer all copper bullets. It's my understanding that the reamers can be changed or recut to change for more free bore and require sharpening. (NOT A GUNSMITH) Aways asking question, and learning, sometime slowly.

Last edited:

Justice1327

Well-Known Member

Get ahold of Shaen (pronounced Shane)

Maegan. He builds tack drivers.

Attachments

I've done a lot of tinkering in my time. Free bore is one of the most difficult 'hard to factor' elements in a custom build. Am wondering if there are even a handful of folks in this thread who have made a study of it and might take the time to elaborate.What does concerns me is the jump or free bore

Freebore design is complicated and somewhat controversial, Chris. Throat dia goes hand in hand with the discussion along with Leade angle design.

Some gunsmiths offer a service where they will "throat" the length of the dummy rounds that the customer provides at a small charge. There are a few gunsmiths that order reamers with the shortest Freebore that any customer would want, then throat out to the desired length of the dummy rounds that the customer provides, and they may charge an hour's shop time for this procedure.

Some gunsmiths offer a service where they will "throat" the length of the dummy rounds that the customer provides at a small charge. There are a few gunsmiths that order reamers with the shortest Freebore that any customer would want, then throat out to the desired length of the dummy rounds that the customer provides, and they may charge an hour's shop time for this procedure.

Mike Matteson

Well-Known Member

With the change of bullet makeup and length of bullet. It seem hard to figure it out the length of chamber. Especially with finding a bullet you like. Being it's BC, weight, and how it does in putting down an animal. What the bullet does to the animal and blood shot areas. The older Nosler Partition bullet if I remember correctly velocity max was 2900fps. I tried some 100grs partition in my 25/06 a very long time ago. Bloodshot a deer from front shoulder to back of the ham on on side. I changed to Leed tips or now BT's and AB's and never had that problem again. Most of those are 3200 to 3300 fps muzzle veloctiy. I don't have the problem of blood shot animals any more. Very few take a 2nd shot to put down. That's generally is needed with poor shot placement.Freebore design is complicated and somewhat controversial, Chris. Throat dia goes hand in hand with the discussion along with Leade angle design.

Some gunsmiths offer a service where they will "throat" the length of the dummy rounds that the customer provides at a small charge. There are a few gunsmiths that order reamers with the shortest Freebore that any customer would want, then throat out to the desired length of the dummy rounds that the customer provides, and they may charge an hour's shop time for this procedure.

So back to freebore or throat length. I believe that not quite right. Freebore is somewhat different than chamber length. Freebore is a cone shape to reduce chamber pressures like WBY chambers, and added length in some rifles are the lands are somewhat a straight or square cut where the bullet enters into the lands. So either you have to bump the bullet back or extend it to create the jump needed for a more accurate round. Mag length comes into play at the same time. I use long action in my rifle builds to overcome some of those problems. I use my rifles to hunt with, so I don't want a single shot rifle either.

We have talked about setting up a portable reloading station to adjust things at the range. I have figured out what I am going to use. and partly how it going to incorpate it into my range time.

Take care my friend!

Hopefully a true expert like Alex Wheeler will respond, but it seems that with modern chamber designs and their tighter tolerances, getting a specific jump to the lands of the barrel is no longer seen as important as it once was. Erik Cortina, one of todays top competition shooters, made a YouTube video entitled: "Chasing the lands is STUPID! Don't to it." The current trend is to just find a combination that works well with a particular rifle/powder/bullet combination and not worry about the length of the jump.

The Weatherby Magnums (and most recent cartridges) use a tube of snug-fitting freebore before the tapered "forcing cone" into the rifling. Some cartridges like the 30-06 or 300 Win Mag just have a cone that tends to be larger at the mouth than the freebore sections for most modern cartridges. The 300 Win Mag's cone, for example starts at .315"dia. The 300 Weatherby mag, in comparison used a .361" long section of snug freebore tube ( 0.3084" dia) to allow the bullet to travel a little farther before hitting the lands and slowing down as the rifling got engraved. This resulted in higher velocity, but required pretty tight tolerances by 1940's standards. Unlike the larger cone of a 300 Win Mag, the tight tolerance on the freebore section of the Weatherby holds the bullet straight as the rifling is engraved. FWIW, the recent 6.5-300 Weatherby Magnum has about half the length of freebore as the 1940's ones, so it seems Weatherby has decided it had too much of a good thing.

The 25-06 is an interesting case, since when it was standardized by SAAMI in 1969, it had what was considered an unusually long and tight section of freebore ( 0.105" long with only 0.0005" clearance). It has the case body of the 30-06, but a freebore/throat design more related to the .257 Weatherby Magnum. The trend for the majority of cartridges released in the past 50 years has been to have a tube of freebore with a thousandth of an inch (or even half of that) clearance around the bullet. This holds the bullet in line with the center of the bore while the rifling is engraved. This had been done with "match chambers" for competition rifles long before it became common with hunting cartridges, so the term "match chamber design" is often used for the 25-06 and many newer cartridges. Today's better tooling and machining processes makes holding these tight tolerances much easier.

The older chamber designs with only an oversized cone for the throat rely on the case to align the bullet with the bore. For a number of reasons, this can allow the bullet to be angled slightly when the rifling is engraved on it. The result is that the rifling is not engraved evenly and the bullet will tend to be cocked very slightly sideways as it spins down the barrel. On some pictures of recovered bullets, it is possible to see this uneven depth of rifling on some of the grooves. When the bullet leaves the confines of the barrel, the forces from the rapid spinning of the misaligned bullet can cause it to jump slightly sideways.

The Weatherby Magnums (and most recent cartridges) use a tube of snug-fitting freebore before the tapered "forcing cone" into the rifling. Some cartridges like the 30-06 or 300 Win Mag just have a cone that tends to be larger at the mouth than the freebore sections for most modern cartridges. The 300 Win Mag's cone, for example starts at .315"dia. The 300 Weatherby mag, in comparison used a .361" long section of snug freebore tube ( 0.3084" dia) to allow the bullet to travel a little farther before hitting the lands and slowing down as the rifling got engraved. This resulted in higher velocity, but required pretty tight tolerances by 1940's standards. Unlike the larger cone of a 300 Win Mag, the tight tolerance on the freebore section of the Weatherby holds the bullet straight as the rifling is engraved. FWIW, the recent 6.5-300 Weatherby Magnum has about half the length of freebore as the 1940's ones, so it seems Weatherby has decided it had too much of a good thing.

The 25-06 is an interesting case, since when it was standardized by SAAMI in 1969, it had what was considered an unusually long and tight section of freebore ( 0.105" long with only 0.0005" clearance). It has the case body of the 30-06, but a freebore/throat design more related to the .257 Weatherby Magnum. The trend for the majority of cartridges released in the past 50 years has been to have a tube of freebore with a thousandth of an inch (or even half of that) clearance around the bullet. This holds the bullet in line with the center of the bore while the rifling is engraved. This had been done with "match chambers" for competition rifles long before it became common with hunting cartridges, so the term "match chamber design" is often used for the 25-06 and many newer cartridges. Today's better tooling and machining processes makes holding these tight tolerances much easier.

The older chamber designs with only an oversized cone for the throat rely on the case to align the bullet with the bore. For a number of reasons, this can allow the bullet to be angled slightly when the rifling is engraved on it. The result is that the rifling is not engraved evenly and the bullet will tend to be cocked very slightly sideways as it spins down the barrel. On some pictures of recovered bullets, it is possible to see this uneven depth of rifling on some of the grooves. When the bullet leaves the confines of the barrel, the forces from the rapid spinning of the misaligned bullet can cause it to jump slightly sideways.

Last edited: