You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

is copper jacket spinning around lead core during flight

- Thread starter Professor Doolittle

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Bagpiper63

Member

With that much heat would it not cauterize the entry and exit wounds? Asking for a friend as I use barnes copper projectiles.

Having recovered a fair number of copper cup bullets from game and other media, I don't notice any signs that the lead core was molten when it hit the game. Very possibly there is a thin boundary layer between the copper and the lead that has melted, but I see no evidence the entire core is molten.

QuietTexan

Well-Known Member

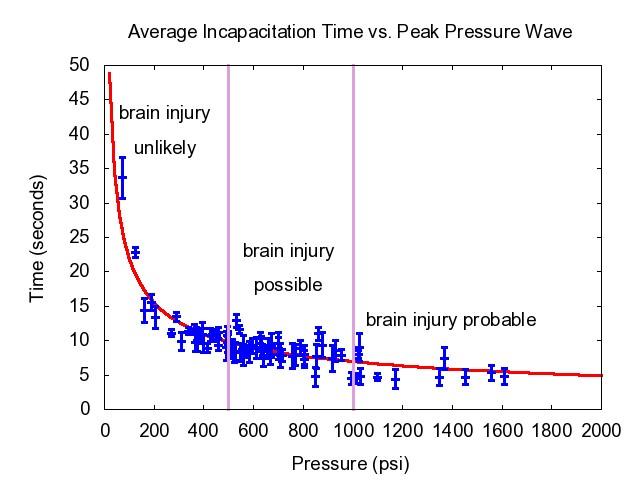

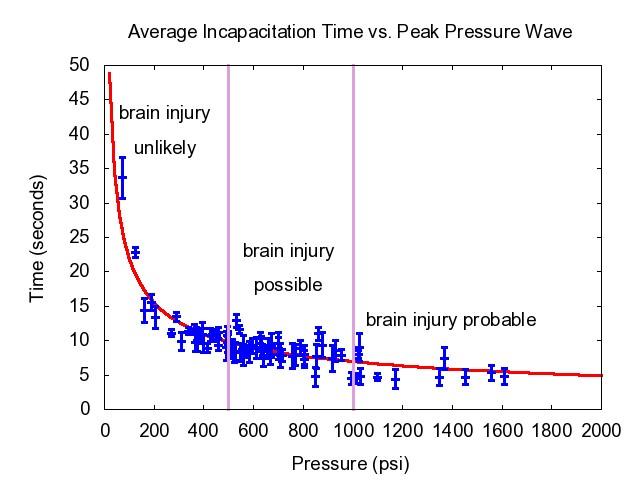

I would think the pressure wave generated from a supersonic projectile would destroy any tissue that would be cauterized - the permanent wound channel created by energy absorbtion would extend deeper into the surrounding tissue than any heat effects could.

A read on blast pressure waves inside an article on hydrostatic shock:

en.wikipedia.org

en.wikipedia.org

A read on blast pressure waves inside an article on hydrostatic shock:

Hydrostatic shock - Wikipedia

MagnumManiac

Well-Known Member

Yes, completely exempt.Is a bonded bullet exempt from this proposed phenomenon.

Cheers.

I only began thinking about this after recovering some 325 grain .45-70 bullets, (which can do weird things). The jacket was of course damaged, as was the lead. However, though the lead had contorted to the approximate shape of the jacket - it was very smooth everywhere, as if it had "flowed" to fill every void in every direction.Something I've always wondered about high power rifles shooting copper jacketed bullets with a lead core. If you had a 12 inch twist on a barrel shooting 3000fps, then at the muzzle the bullet is spinning at 3000 revs per second, times 60 which is 180,000rpm. If its a 9 inch twist then its 240,000rpm. That means this heavy mass goes from 0 to 240,000rpm in about 2 milliseconds. That's incredible moment of inertia. Now, Lead melts at 621 degrees F and is a heavy mass, yet the copper jacket is being spun around the lead which is probably either liquid or close to it, very soft. The question to be answered is does the lead core reach melting point but I think its possible that these copper jackets are spinning around the lead core which is moving at a slower rotation. Does it cool down and match speed with the copper jacket in the next 1.5 seconds before it hits the target? I doubt it. It might even be getting hotter from the air friction. Maybe they put some baffling in the empty jacket to keep this from happening even if the lead is liquid, I don't know.

Despite this, the lead slug can be easily removed from the jacket using only your fingers. (Not sure if this proves anything or not)

I began considering your theory too while shooting 4000 fps factory loaded .22-250 ammo as well. That's A LOT of heat AND some serious RPMs!

IF the initial & acquired heat does melt any lead I don't see as it would affect accuracy any because, IMO, the crazy centrifugal force would sling it out equally in all directions.

I too have seen very rare "splatter" before when shooting rifle bullets through paper splatter targets on cardboard.

I love what I believe it was Tom Beckstrand of Guns & Ammo once said: "I attribute that to weird things that guns do. Sometimes there's just no explanation!"

I like your thinking outside the box Prof.

DUSTY NOGGIN

Well-Known Member

if it got that hot .. then abruptly stopped, wouldnt you see some cooked animal parts directly around the stopped mushroomed bullet ??

i mean if were speculating that it get liquid hot in milliseconds .. does it also cool in milliseconds

i mean if were speculating that it get liquid hot in milliseconds .. does it also cool in milliseconds

Last edited:

billflangjr813

Well-Known Member

- Joined

- May 21, 2014

- Messages

- 235

I don't think So.Something I've always wondered about high power rifles shooting copper jacketed bullets with a lead core. If you had a 12 inch twist on a barrel shooting 3000fps, then at the muzzle the bullet is spinning at 3000 revs per second, times 60 which is 180,000rpm. If its a 9 inch twist then its 240,000rpm. That means this heavy mass goes from 0 to 240,000rpm in about 2 milliseconds. That's incredible moment of inertia. Now, Lead melts at 621 degrees F and is a heavy mass, yet the copper jacket is being spun around the lead which is probably either liquid or close to it, very soft. The question to be answered is does the lead core reach melting point but I think its possible that these copper jackets are spinning around the lead core which is moving at a slower rotation. Does it cool down and match speed with the copper jacket in the next 1.5 seconds before it hits the target? I doubt it. It might even be getting hotter from the air friction. Maybe they put some baffling in the empty jacket to keep this from happening even if the lead is liquid, I don't know.

Years ago, in my 223 nef I managed to toss some hornet bullets in the 30s weight class to a speed of 4100fps in a 12twist. They to stayed together. I thought they would liquified but no!It seems like there would be a convective transfer issue where the lead core is not evenly heated and would not uniformly liquify. There would be a boundary layer formed between the jacket and solid portion of the core, and as small as bullets are a shear flow layer would form and the relatively high viscosity of lead at its melting point would resist the shearing motion, so the non-uniformly liquified lead core would still rotate along with the jacket. This might be why bonded jacketed bullets perform better than straight cup and core bullets at higher impact velocities/ faster twist barrels, because the core and jacket have a chemical bond that has to be overcome, not simply a convective heat transfer from one metal to another.

I'm not convinced the core actually melts, I don't know how to calculate it but I'm sure some engineer could do the math on how much heat the core absorbs by convection over the relatively short time window of the bullet's flight. Think of the RPMs of a 36gn Varmint Grenade going 4000FPS out of a 12-twist 22-250. Those bullets hold together, and they function by having a sintered metal core that fragments when it hits the target. I'm sure the melting point of the copper-tin powder is higher than lead, but there's also significantly less mass available to absorb heat from the shot. If the core was melting it wouldn't explosively fragment the way that we see them do in ballistic gel.

DMP25-06

Well-Known Member

Something I've always wondered about high power rifles shooting copper jacketed bullets with a lead core. If you had a 12 inch twist on a barrel shooting 3000fps, then at the muzzle the bullet is spinning at 3000 revs per second, times 60 which is 180,000rpm. If its a 9 inch twist then its 240,000rpm. That means this heavy mass goes from 0 to 240,000rpm in about 2 milliseconds. That's incredible moment of inertia. Now, Lead melts at 621 degrees F and is a heavy mass, yet the copper jacket is being spun around the lead which is probably either liquid or close to it, very soft. The question to be answered is does the lead core reach melting point but I think its possible that these copper jackets are spinning around the lead core which is moving at a slower rotation. Does it cool down and match speed with the copper jacket in the next 1.5 seconds before it hits the target? I doubt it. It might even be getting hotter from the air friction. Maybe they put some baffling in the empty jacket to keep this from happening even if the lead is liquid, I don't know.

This is an interesting theory .

I happen to think along a different viewpoint about the lead cores melting inside the copper jackets .

For many years I hunted with a 7mm Remington Magnum shooting 150gr Nosler Partition bullets at a chronographed velocity of 3250 FPS average , out of a 1:9.25" twist barrel , that would mathematically achieve a rotational speed of 252,972 RPM's . THAT SHOULD GENERATE SUBSTANTIAL HEAT AND CENTRIFUGAL FORCES , according to the theory expressed above.

If you are familiar with the Nosler partition bullets , and you examine a cross-sectioned partition bullet , you will see that the copper jacket is drawn in a shape that resembles the letter H , with lead being above and below the partition , with a visibly exposed lead tip , and a visibly exposed much broader lead base with the copper jacket minimally closed around edges of the lead base to hold it in place .

I have only recovered 3 of these Partition bullets from inside animals (all others exiting) , and in all 3 recovered bullets only the jacket and rear core were found . The lead inside the rear of the Partition looked to be perfectly smooth , with no evidence of heat deformation from being exposed to the blast heat . The surface of the lead looked just as smooth and unmarked as the surface of a new Partition bullet out of a new box .

If all of this heat is generated , shouldn't the lead base have shown markings indicating the beginning of melting ?

Now , after having listed my personal experiences and observations , I will post my theory about the heat from the burning of the powder effect of heating the bullet/projectile .

I think that the bullet is being pushed/propelled out of the barrel by a pressure wave created by the burning rapidly expanding gases generated by the burning gunpowder .

When i have watched extreme slow-motion video of bullets exiting the muzzles of different firearms , the bullet is always several inches ahead of the flash/fireball of the burning powder.

THIS IS JUST MY OPINION . I am NOT trying to argue with anyone on this subject .

One final observation about the theory of the melting of the exposed soft lead tip of spitzer shaped bullets while in flight .

While hunting in the mountains of Colorado in 1984 , I once found a bullet that had fallen to earth , not having hit any animal or object , just laying on the ground . The copper jacket was scribed by the lands of the rifle barrel , and the forward tapered nose was slightly bent , flattened , and scratched on one side from falling from the sky to the earth , and the exposed soft lead tip was still there on the tip of the bullet , although bent and scratched also .

I kept this bullet as a trophy/memento from my hunting trips , and I have it stashed away somewhere .

DMP25-06

Some thoughts:

- It's less heat from the burning powder, because the bullet is being pushed by a powder column as it burns up from the bottom, and more from the friction pushing it down a barrel. Common sense dictates that you would expect this phenomena to occur more frequently in longer barrels.

- For kicks and grins, fire a shot into a shallow portion of a lake so you can fetch the otherwise untouched bullet, and then section it.

- I would suspect that your stability would go out the window because your spin rate would drop precipitously due to the internal friction created by the lead phase change, and the copper would slow to whatever the lead core was spinning at.

- Sounds like a good reason to start using monos exclusively.

ntsqd

Well-Known Member

It seems to me that the distortion of the jacket caused by the rifling would tend to "key" the core to the jacket. If the core still manages to spin relative to the jacket this keying would require that the boundary layer of molten lead to be quite thick. Which makes this possibility all that much harder to have happen. Thick bullet jackets will display less distortion on the jacket interior surface than would a thin jacket. Given which bullets tend to get thick jackets and which tend to get thick jackets this should make relative motion between the core and the jacket even less likely.

- Joined

- Jan 26, 2015

- Messages

- 1,903

You also have to account for the rifling deforming the building material into the lead which would form a mechanical lock of sorts. I know my statement has nothing to do with the heat generated, but would help eliminate the sepate rotation of the two substances.

This whole discussion unnerved me. I thought to myself "aha there's the reason for that occasional unexplained flyer out of a perfect group". I just did an experiment with three different bullets. Nosler 180gr .30cal protected tip partition, Sierra 200gr game king 30cal, Hornady 123gr interlock 30cal. I put a bullet securely in vice grips, not enough to deform or mar the copper jacket. I have a torch that, with the gas mixture in use, has a temperature of between 1,400F and 1,500F, far above the melting point of lead at 621F. Copper melts at nearly 2000F

For each bullet it required 5+ seconds of direct exposure to the flame before the lead started to deform, and 7 seconds before it liquefied and ran out of the copper jacket. Interesting to note that with the Partition it took longer for the base lead to melt suggesting to me that the lead in the base is a different alloy with a higher melting temperature. For the split second that a bullet is in a rifle barrel, it looks like it is impossible for powder ignition heat or barrel friction to act on the bullet long enough to cause anything to melt. Manufacturers proved, some time back, that friction with the air, could cause melting of tips of the early poly-tipped bullets. I've pulled freshly fired bullets out a dirt backstop that were too hot to hold in my hand. That I believe is due to the friction of the bullet coming to a dead stop in the soil. I don't think that this melting hypothesis is very likely to happen at all, but it has created some interesting discussion.

For each bullet it required 5+ seconds of direct exposure to the flame before the lead started to deform, and 7 seconds before it liquefied and ran out of the copper jacket. Interesting to note that with the Partition it took longer for the base lead to melt suggesting to me that the lead in the base is a different alloy with a higher melting temperature. For the split second that a bullet is in a rifle barrel, it looks like it is impossible for powder ignition heat or barrel friction to act on the bullet long enough to cause anything to melt. Manufacturers proved, some time back, that friction with the air, could cause melting of tips of the early poly-tipped bullets. I've pulled freshly fired bullets out a dirt backstop that were too hot to hold in my hand. That I believe is due to the friction of the bullet coming to a dead stop in the soil. I don't think that this melting hypothesis is very likely to happen at all, but it has created some interesting discussion.