I do not have a 6.5 PRC, but I have a .264 WM, and the IMR 4831 is one of the recommended powders that Hornady recommends. It would not be my first choice of powder or bullet, but it is no slouch. While we can recommend different powders, the OP is in Canada and might not have the same powder accessibility (or cost-effectiveness) as in the US.I could be wrong but IMR 4831 is likely a little fast of a powder for the 143. Check out the Hodgdon reloading data center, see what they recommend. With the 143 in a 6.5 PRC you're in the H1000 to Retumbo range for powder. Other comparables would be Vihtavouri N570 or N568, Alliant RL26, letc. This would get you closer to case fill and hopefully get the speed up, those velocities are pedestrian for 6.5 PRC with a 143. I'd suggest searching this site for load data on the 6.5 PRC and 143, you might get a head start and save yourself a bunch of time.

If you're set on the powder, go to a lighter bullet, something in the 120 to 130 class is probably more appropriate for that powder.

With this being your first load ever, thought I'd share what I normally do. Others may disagree, hopefully this helps.

After I've selected the powder, start on the low end. Seating 0.020 off the lands run a test to find pressure, going up 0.5 grains at a time. Monitor velocity on all of these looking for a node, but also shoot all of these rounds at the same spot, looking for consistency in poi and note any changes. Stop when you hit the max load, or find pressure, whichever comes first.

Then I pick a charge weight to start developing from that data (based on consistency of poi and velocity), and start testing seating depths, backing away from the lands 0.005 or 0.010 at a time, 3 shot groups. I've not spent a lot of time with the ELD's, but most bullets have a range of jump from the lands that they prefer. See if you can find that info to save yourself some time and components.

When I find the best seating depth, I come back to the powder, do an OCW test at a minimum of 200 yards. Loading in 0.3 grain increments over a 1.5 to 2 grain range around the node to find the right powder charge. This usually gets me well under MOA.

However, sometimes a barrel doesn't like a powder/bullet combo. Learning how to identify this early on and move on to other options can be a challenge.

I'd also add that consistent neck tension is very important in getting your es down and improving your groups. Make sure your cases are chamfered and deburred. Lube the inside of the necks. Some bullets have a sweet spot for neck tension, I'm usually running 0.025 or 0.003 for best results. Hard to believe that 0.005 in NT could make a difference, but it definitely can. Time spent on these details pays off

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extreme spread and standard deviation vs accuracy

- Thread starter southernfella

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Doom2

Well-Known Member

You are shooting a hunting rifle not a bench rest rifle so you will seldom if ever shoot more than three rounds so trying to shoot 5 shot groups is something the rifle isn't designed to do with a light barrel. But I would speculate that the lower load is just that, too low to get a good standard deviation. Looking at your higher loads show your loading good ammunition. You need to run a ladder or an OCW test to find a charge that looks good on target.

southernfella

Member

I was thinking of trying 4831scI think it's important to know that 3 shot and 5 shot groups can give you just a small peak at total dispersion.

Small sample sizes.

There's a video by Hornady, called "Your groups are too small." It's a bit controversial, but I think there's some truth to it.

Also, I've had similar issues and I find that I usually avoid the hottest loads, for various reasons. At the end of the day never adjust more than one variable at a time and maybe try 10 shot groups.

My 6.5 prc will stack twenty shots into a 1.5" groups at 200yds. It will also shoot 1.5inch 5 shot groups at 100yds. And finally it will consistently shoot 3" groups out to 600yds. Reload for your purpose.

But my sd/es are always low and I think that plays a very important role in my longer range work.

Never used imr4831... But have had great results with h4831sc,n165,and n170. Also, went away from magnum primers due to availability, and I don't think I'll go back. My numbers are better without them.

Make small tweaks and shoot more. Or change a component.

Good luck. LMK if you want my pet loads.

I do have 4831sc available, I think it's the same burn rate. What are your loads and velocities? I feel like mine are slow but I started to get pressure signs before I even touched 2900fpsI think it's important to know that 3 shot and 5 shot groups can give you just a small peak at total dispersion.

Small sample sizes.

There's a video by Hornady, called "Your groups are too small." It's a bit controversial, but I think there's some truth to it.

Also, I've had similar issues and I find that I usually avoid the hottest loads, for various reasons. At the end of the day never adjust more than one variable at a time and maybe try 10 shot groups.

My 6.5 prc will stack twenty shots into a 1.5" groups at 200yds. It will also shoot 1.5inch 5 shot groups at 100yds. And finally it will consistently shoot 3" groups out to 600yds. Reload for your purpose.

But my sd/es are always low and I think that plays a very important role in my longer range work.

Never used imr4831... But have had great results with h4831sc,n165,and n170. Also, went away from magnum primers due to availability, and I don't think I'll go back. My numbers are better without them.

Make small tweaks and shoot more. Or change a component.

Good luck. LMK if you want my pet loads.

southernfella

Member

There is an incredible shortage right now, primers are selling close to a dollar from scalpers and powder is $100/lb in the store. I've been looking for retumbo but it's pretty scarce even from scalpersI do not have a 6.5 PRC, but I have a .264 WM, and the IMR 4831 is one of the recommended powders that Hornady recommends. It would not be my first choice of powder or bullet, but it is no slouch. While we can recommend different powders, the OP is in Canada and might not have the same powder accessibility (or cost-effectiveness) as in the US.

Yep, that's crazy!There is an incredible shortage right now, primers are selling close to a dollar from scalpers and powder is $100/lb in the store. I've been looking for retumbo but it's pretty scarce even from scalpers

IIRC, I paid $50/lb for Retumbo. I started this thread 3 years ago just for fun,

"My" never leave the local gun store empty-handed rule ...

That is what I am shooting and only have 10 left. But my coworker has 100 that he will sell. Got lucky.

and it's amazing how much I have accumulated with incremental investments.

StumpyJohnson

Well-Known Member

I'll get some data when I get back to the house. But I push hammer hunters and the cx120 around 3150. And 130 grain Bergers around 3050. 2900 is fine for sure but I think 4831sc and vv n165 are slower than imr4831 by a fair amount respectively. You should get a bit more speed with a bit less pressure with those powders.I was thinking of trying 4831sc

I do have 4831sc available, I think it's the same burn rate. What are your loads and velocities? I feel like mine are slow but I started to get pressure signs before I even touched 2900fps

StumpyJohnson

Well-Known Member

For my hunting loads I use a timer to wait 2-4minutes between shots, depending on ambient temp. Then I shoot 5 or 10 shot groups. This helps me dial the load to cold bore conditions. My initial ocw 5 end groups and usually .7 grain increments or higher. Then 10 shot groups at . 3 grain increments based on the previous round. Always with a timer between shots. It seems like I'd be shooting a ton of rounds that way but I actually seem to shoot less. Because my data seems to be more accurate and proven. From break in to developed load I average about 75 rounds.You are shooting a hunting rifle not a bench rest rifle so you will seldom if ever shoot more than three rounds so trying to shoot 5 shot groups is something the rifle isn't designed to do with a light barrel. But I would speculate that the lower load is just that, too low to get a good standard deviation. Looking at your higher loads show your loading good ammunition. You need to run a ladder or an OCW test to find a charge that looks good on target.

Personal experience with the 6.5 Prc, h4831 great powder, h1000, Retumbo, n550, n560. Don't see the advantage in running a 215 primer. Fed 210 primers seem to run a better es and sd in the powder column. Personally I don't see a reason to run a magnum primer in cartridges that are less than 70-75 grains of powder. The powder column is not very long, and the burn rate of powder is faster in short magnum cartridges. The only time I run H1000 or Retumbo is on finicky barrels. H4831 is like hitting the staples easy button.

Last edited:

Run the 210 primer in the PRC not the 215.

You should be able to find a very accurate load with the 143's in the 2900-3000 range and, most likely, a bit faster. I run mine around 2930-2950.

I've had great luck with H4831SC, N560 and N565 with that combination. In shot, try other powders.

You should be able to find a very accurate load with the 143's in the 2900-3000 range and, most likely, a bit faster. I run mine around 2930-2950.

I've had great luck with H4831SC, N560 and N565 with that combination. In shot, try other powders.

Hugnot

Well-Known Member

This is of some interest to me as a will be shooting a 6.5PRC soon. I expect better velocities than the 6.5-06 using 140 grain bullets. There must be a good reason to spend more money and time looking for brass. I also have a good supply of CCI 34 primers that provide good results with ball powders. Extruded powders are not made in the USA and periodic shortages of extruded powders occur.

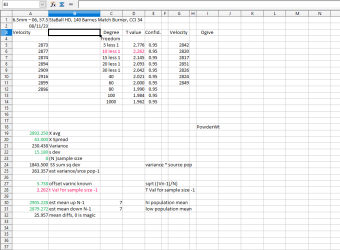

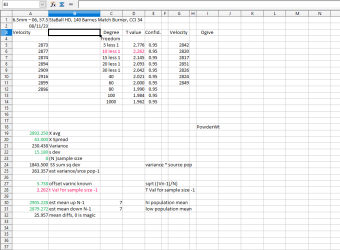

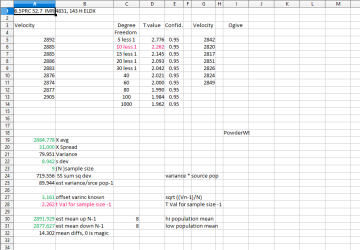

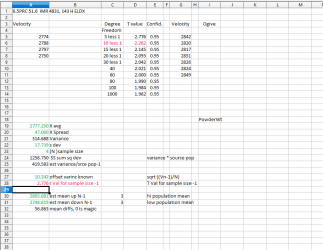

Playing with the data:

This is the data for my 6.5-06 loads using Staball HD. I can buy SBHD at 2 LGS for about $40 / pound. Accuracy is real good, like 4 in same hole & 1 about 3/8 out. Extreme spread needs more work. My LGS has lots of CCI 34's selling for about $85 / 1,000. Periodic shoots have produced equal accuracy. I plan shooting at 1,000 and at long range rodents next spring with the 6,5 PRC. Running the Hornady 4DOF number stuff shows the 6.5 140 ELDM outperforming other lighter 6.5 ELDM bullets at ranges greater than 400-500 yards.

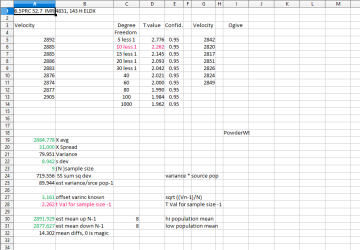

OP's data.

This shows promise. Toss out the last value of 2905 and that difference of 14 fps between average hi-low would be less. I combined data for both groups as the same 52.7 grain powder charge was used for both. Velocities are similar to cheap to shoot 6.5-06.

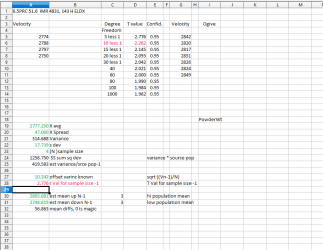

OP's Data

This is data from the 51.6 grain IMR 4831 load with 143 HELDX bullets. Appears to group good but not enough data to provide consistency as shown by hi Tval & big diffs between hi-low averages. This is because only 4 samples were used.

My humble suggestion would be to migrate to another powder like VN 165, H1000, Staball HD- whatever can be had. Double base powders would provide higher velocities per weight.

My plans for my new 6.5 PRC are to buy whatever is the cheapest & most available to provide optimum velocities, accuracy & narrow average velocity differences. The goal being production of a batch of 200-300 rounds with minimum extreme spreads and acceptable accuracy. If velocities are not greater than 100 fps with more accuracy and consistency than the 6.5-06 there would not be any logical reason to spend more money on 6.5 PRC brass & a new rifle build. I plan to start my 6.5 PRC ammo production with SBHD, 140 ELDM bullets, CCI 34 primers & Hornady 6.5 PRC brass. My LGS has all of this.

I like the way SBHD goes thru my powder measure.

Playing with the data:

This is the data for my 6.5-06 loads using Staball HD. I can buy SBHD at 2 LGS for about $40 / pound. Accuracy is real good, like 4 in same hole & 1 about 3/8 out. Extreme spread needs more work. My LGS has lots of CCI 34's selling for about $85 / 1,000. Periodic shoots have produced equal accuracy. I plan shooting at 1,000 and at long range rodents next spring with the 6,5 PRC. Running the Hornady 4DOF number stuff shows the 6.5 140 ELDM outperforming other lighter 6.5 ELDM bullets at ranges greater than 400-500 yards.

OP's data.

This shows promise. Toss out the last value of 2905 and that difference of 14 fps between average hi-low would be less. I combined data for both groups as the same 52.7 grain powder charge was used for both. Velocities are similar to cheap to shoot 6.5-06.

OP's Data

This is data from the 51.6 grain IMR 4831 load with 143 HELDX bullets. Appears to group good but not enough data to provide consistency as shown by hi Tval & big diffs between hi-low averages. This is because only 4 samples were used.

My humble suggestion would be to migrate to another powder like VN 165, H1000, Staball HD- whatever can be had. Double base powders would provide higher velocities per weight.

My plans for my new 6.5 PRC are to buy whatever is the cheapest & most available to provide optimum velocities, accuracy & narrow average velocity differences. The goal being production of a batch of 200-300 rounds with minimum extreme spreads and acceptable accuracy. If velocities are not greater than 100 fps with more accuracy and consistency than the 6.5-06 there would not be any logical reason to spend more money on 6.5 PRC brass & a new rifle build. I plan to start my 6.5 PRC ammo production with SBHD, 140 ELDM bullets, CCI 34 primers & Hornady 6.5 PRC brass. My LGS has all of this.

I like the way SBHD goes thru my powder measure.

ResearchinStuff

Well-Known Member

Lots of confusion about what hornady actually said.

Load up 1 combo somewhere below max, shoot 10 in that group. If it hits your accuracy goals load the rest and go practice. If it doesn't, change powder or bullet and try again. Seating depth, minute powder charge differences, ladder tests etc do not produce statistically valid or repeatable results.

Load up 1 combo somewhere below max, shoot 10 in that group. If it hits your accuracy goals load the rest and go practice. If it doesn't, change powder or bullet and try again. Seating depth, minute powder charge differences, ladder tests etc do not produce statistically valid or repeatable results.

ResearchinStuff

Well-Known Member

It's not enough data to say. I've had some pretty horrible groups that managed to throw 3 into a similar part of the cone. It really takes about 10 shots for the group size to become even kind of repeatable.

From the podcast.

From the podcast.