Thanks easy to use…

I wonder why it doesn't require barrel length or have a minimum length ? I'm

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Thanks easy to use…

Because barrel length doesn't have anything to do with stability.Thanks easy to use…

I wonder why it doesn't require barrel length or have a minimum length ? I'm

Barrel length is a factor in muzzle velocity.Thanks easy to use…

I wonder why it doesn't require barrel length or have a minimum length ? I'm

Correct, but MV does.Because barrel length doesn't have anything to do with stability.

Regardless of the bullet stability calculator used, i.e., as provided in #11, factors affecting SG are already provided. Any changes in one of those attributes will affect the SG. Don't overcomplicate it unnecessarily.If I have a bullet that is close to stabilizing, say it needs 9" twist and I have a 9&1/2 twist barrel would increasing the velocity (bullet rpm) help stabilize it? I realize that the bullet will still have the same rotation to distance ratio but can it be fooled?

What do you mean [exactly] by 'marginally stable' for that scenario?I ran this very scenario last night for a hammer bullet on Bergers stability calculator.The 51 gr AH in a 10 twist is marginally stable at 3000 fps and stable at 3300 fps

I know this is technically right on. On the other hand we see long for caliber bullets holding sub half moa but then swapping ends at 1300y. Speed still well away from transonic with stability technically getting higher the farther out the bullet travels but then hitting a point the heavier end of the bullet passes the lighter front end. Which is where it wants to be and we stop it from happening by spinning the bullet. There comes a point where dynamic stability trumps ballistic stability and then it is all thrown out on its ear. It is most definitely a head scratcher.The Miller stability or Sg calculator is only an estimator providing a ratio, like over 1.0 having neutral stability & 1.5 having adequate stability.

The Miller method is widely accepted and is used by Berger & JBM. Berger uses an altitude pressure table vs. actual barometric pressures. It (Miller) does not consider large cavities in bullets like the 107 grain 6.5 Sierra hpbt that appears to have close to 20% void at tip (material density). Plastic tips are factored in by an operation like (H25 - H26 / H23) ^2, as shown in the calculation spread sheet.

Sg values increase down range as bullet velocity decreases rapidly and effects such as yawing & pitching decrease while bullet revs decrease very slowly with TOF being short (spinning like crazy, lots of RPM's like over 300K in some cases)

From Hornady;

"The pitch and yaw angle is continually getting smaller because the bullet is dynamically stable."

This makes Sg values increase as velocity decreases.

Velocity only has a minor effect on Sg values, like:

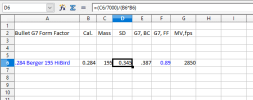

View attachment 464841

Note the Sg value creeps up from 1.65 to 1.68 with a 150 fps velocity increase - no big deal.

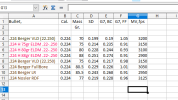

Form factor is another important consideration giving rise to lighter bullets that can be driven faster, like:

View attachment 464843

I like the .224 75 grain ELDM in my 7.7 twist .22-.250's because it provides good ballistics at low cost, like under $30 for 100 & powder charges in the mid 30 grain range. The .224 80 grain ELDM has higher G7 BC values but cannot be driven as fast, however the 80's give slightly better numbers using Hornady's 4DOF program with ranges up to 1000 with 100 fps slower MV's.

I have no plans to shoot some real big beast with my little .22-.250 with 75 grain ELDM bullets but I have plans for some programming compiler on my computer so I can quit messing with spread sheets like (H25 - H26 / H23) ^2