JE Custom - Your reply prompted a memory flash. Don't have those very often anymore...... so I cherish them when they do!

My recollection suggests that you are correct. Thats how this whole 11 degree thing got started.

But I also remember now that a group of benchrest shooters reviewed the military data and then wore out a few barrels testing the angles further to see how the military photo results affected accuracy. They found that an 11 degree crown also seemed to produce the most consistent accuracy.

I don't remember where I saw this. It may have been in the Rifle Magazine, in Precision Shooting Magazine, or in Handloader Magazine. I suppose it could have been in one of the many books I had too - "The Accurate Rifle" comes first to mind. It sure as heck wasn't the internet. Contrary to popular belief, the internet did exist back then but a multitude of BBSs and Compuserve was about as good as it got - and they were pretty poor.

I threw out all my old magazines when my self appointed management threatened to divorce me. So I tried to find something on the net to corroborate my memory. I could only find the short description in the following link:

Barrel crowning (Bart Bobbitt)

Accuracy back then wasn't what it is now - although still **** good. So maybe recent improvements have shown this to be a flawed conclusion. In any event, I think that even if the precise angle does make a difference, it isn't likely important for anything but the finest competition rifle and probably couldn't be detected on the finest long range hunting rifle.

That said, I know of no evidence to suggest that any other angle is better than the 11 degree crown, so as they say "In the absence of any compelling information to the contrary", I'll stick with what I currently know won't hurt - 11 degrees.

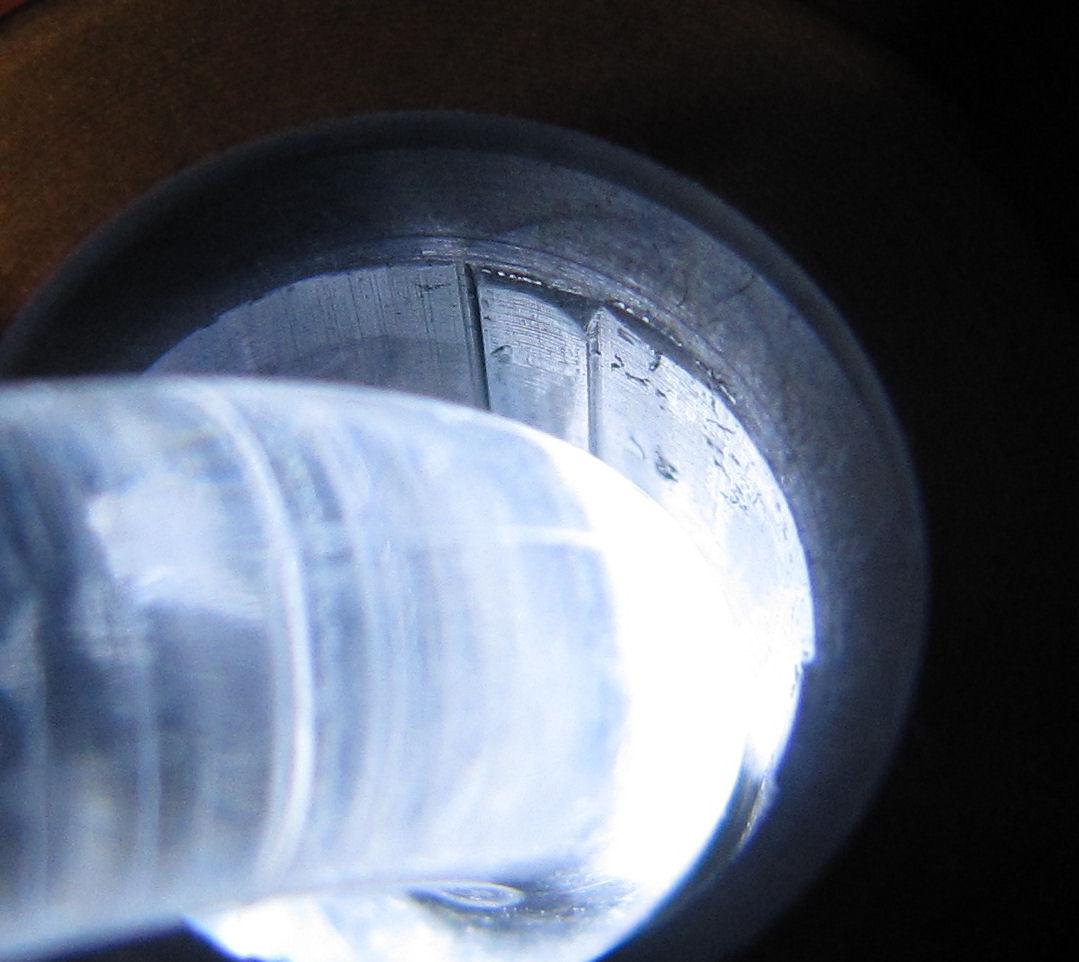

BTW, I found this forum because I was looking for info on how the OEMs make their crowns. I recently purchased a Browning X-Bolt White Gold. Its never been fired. But it appears to have some crown damage in it that is hard to explain. Other damage I have seen is easy to explain by poor tooling and the like. But this is very different. The metal actually appears to have been melted at the crown edge and there are little tiny beads of metal welded to the edge.

Here is a photo taken with a digital camera in Macro mode using a bore light. The loose stuff in the barrel is just dust.

Does anyone know how this happened? My best theory is a lathe centering tool that came loose and spun in the barrel. But its hard to imagine how that could have happened at the factory. I'm contemplating either re-crowning the rifle or re-barrelling it.

Cheers!