whitetail predator

Member

- Joined

- Jan 22, 2011

- Messages

- 6

what is the actual purpose and benefit of crowning a barrel

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

what is the actual purpose and benefit of crowning a barrel

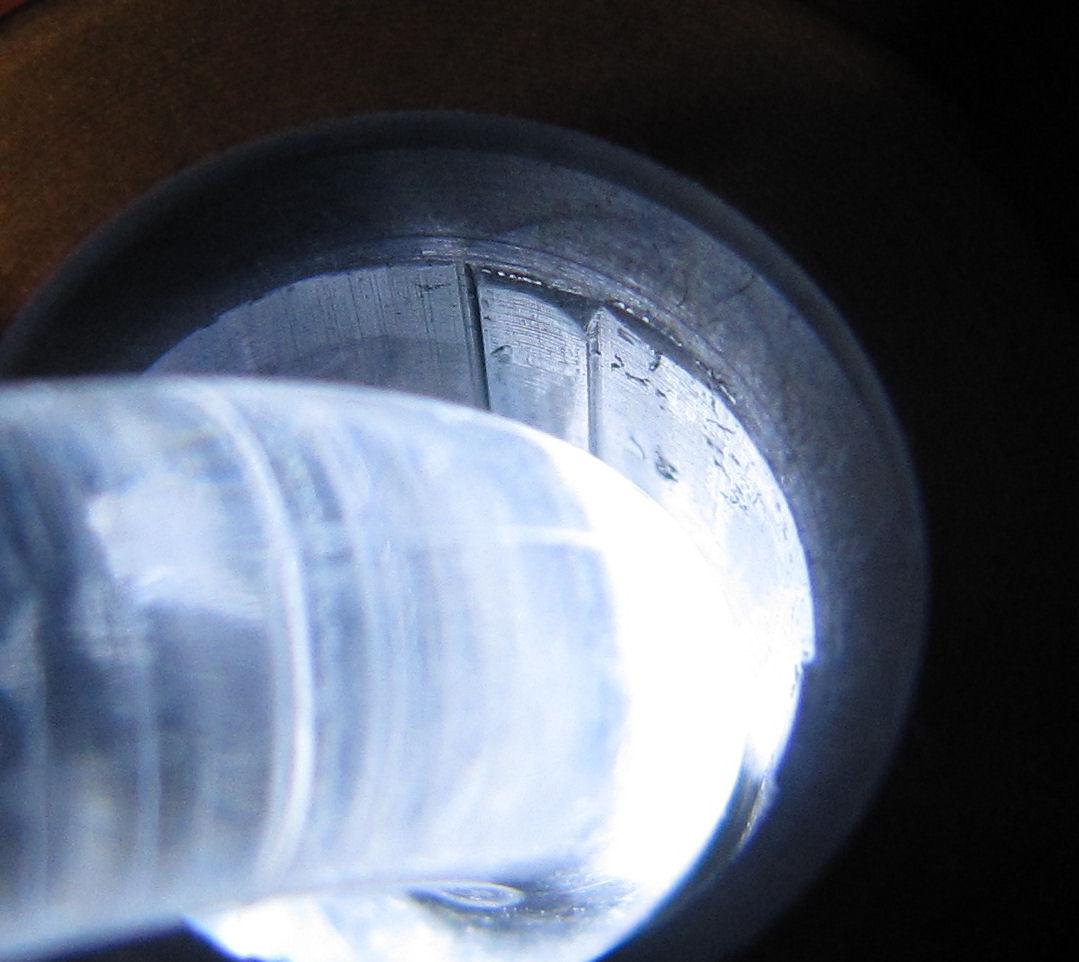

It aids in the bullet and gasses leaving the barrel cleanly and uniformly.

Improving accuracy.

The bullet is under complete control of the barrel until it exits and any unevenness in

the gas escaping can push the bullet off course.

When a proper crown is used It is sharp and square to the bore. This is the reason it is best

not to clean from the muzzle end of the barrel if possible because you can damage the crown

and hurt the accuracy.

J E CUSTOM

I don't know if that's a true statement.Then when gunsmiths put a brake on the muzzle, gas goes every-which-way. So most agree that crowning is not critical and just make a 90 degree cut. Strange.

I don't know if that's a true statement.

(1) You still need a decent crown even if it's not recessed, although I prefer recessed even though you're installing a brake. Simply making a 90 degree cut would leave burrs.

(2) Gas doesn't "go everywhere" until the bullet is free of the barrel. The brake should be about .020" over sized. If the bullet touches the brake, you're screwed.

-- richard

Someplace over 30 years ago, I recall reading that the military did exhaustive testing which showed that 11 degrees was the optimum crown angle for best accuracy. Not by a huge margin, but still significant enough to be the recommended angle of choice.

However, I also recall that this assumed a perfectly perpendicular cut.