What primer? CCI400s?Well, small primers did not work out. In testing both a 120 grain Sierra SP and a 129 ABLR with H4350, I got blown primers in the same spot during ladder testing about 1 grain below max. I got excellent results with the LRP and the 120 Sierra. So, I will set those cases back for an emergency.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor Small Primer for Hunting

- Thread starter USAFRet

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Shooting pard was shooting his 6.5 Creed with Stabal. He got a LOT better accuracy with large primers vs small. It may just have been his gun's preference...you never know.

YesWhat primer? CCI400s?

Flatbow

Well-Known Member

That's a bugger.

I have never had a problem with Lapua srp using cci 400's.

And good accuracy

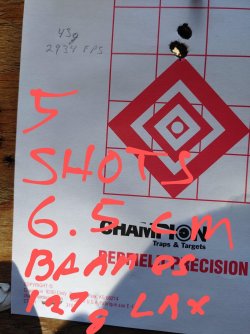

After putting 3 in the same hole I had to hold a smidgen high just to make sure that is what was happening.

This was my first five rounds with this recipe when I developed this load

I have never had a problem with Lapua srp using cci 400's.

And good accuracy

After putting 3 in the same hole I had to hold a smidgen high just to make sure that is what was happening.

This was my first five rounds with this recipe when I developed this load

Attachments

I would recommend CCI450s for using SRP brass for calibers typically using LRP.

Varmint Hunter

Well-Known Member

I'm using CCI 450 primers in Lapua SRP brass in my Creed. I have no problem keeping groups below 1/2moa at 400yds. The rifle is a pleasure to shoot compared to all the heavier stuff that I regularly shoot.

That's my answer. I figured I would try the standard SRPs and it did not work. I will give the magnum primers a try.

Grey Goast

Well-Known Member

what powder did you use?That's a bugger.

I have never had a problem with Lapua srp using cci 400's.

And good accuracy

After putting 3 in the same hole I had to hold a smidgen high just to make sure that is what was happening.

This was my first five rounds with this recipe when I developed this load

That's extremely odd. But if you have a REM 700 action and standard firing pin diameter it's possible. I sent my wife's 6.5x47 Lapua off to LRI and had the pin bushed and smaller diameter pin installed and I get zero primer flow now.Well, small primers did not work out. In testing both a 120 grain Sierra SP and a 129 ABLR with H4350, I got blown primers in the same spot during ladder testing about 1 grain below max. I got excellent results with the LRP and the 120 Sierra. So, I will set those cases back for an emergency.

Also Alpha brass uses small primers but keeps the larger flash hole diameter.

Flatbow

Well-Known Member

RL 16. Pushing a 127 gr Barnes LRX to 2935 fps in 22" barrelwhat powder did you use?

Yes, us scroungers can find them, once in a great while. I don't expect to see the Wolf/Tula primers ever imported again in my lifetime.

I've still got 3,700 of the Tula LRM and 1,000 of the SRM sitting in a closet, probably won't ever use them. If you're ever in Indiana, lmk and we'll get together...

They are great primers, just have to find the load that they like. Thank you!

Man I've had more misfires with Tula primers than any other. Both small pistol and small rifle magnum.

Hugnot

Well-Known Member

I use CCI450's & CCI 41's in SRP 6CM & 6.5 CM with extruded powders like H4350.

For ball powders I like Rem 7 1/2's

This attachment might be of interest -

Table 1 gives info - Rem 7 1/2's are real sparky - don't let stuff like kPA (kilo Pascals- unit of pressure - Pascal is 1 newton per 1 square meter) deter you from reading this. Newton is force needed to accelerate/move 1 kg mass 1 meter per second per second

My 6.5CM & 6CM run on a steady diet of Staball 6.5 & Rem 7 1/2's. The 6.5CM with max loads of R-S Hunter & 120's at 3,000 fps, approaches the famous .270 Win for practical results, like dead deers. Dependable results at temps under 30 F.

6.5 CM ammo having CCI 41's & RS Hunter exhibited wide swings of velocity and printed double groups at 300, like two 4-7 shot groups 4-5 inches apart at 300. Not to be used, especially in cold temps.

Extruded powders are no longer made in the USA - read about horrific explosions that devastated multi acres & busted windows 1/2 mile away when 10 or more tons of powder ignited during drying stage (solvents). WWI - machine gun & other stuff use - death & destruction ending with Spanish flu taking 1/2 mil more lives worldwide. A visit to the abandoned, sad, & desolate Belmont town cemetery in Montana has many graves of Spanish flu victims. One grave marks the life of a USN sailor who was "lost at sea" during the WWII battle of Okinawa. My grandparents were immigrants from France and served a strong woman who volunteered as a WWI battle field nurse then cared for Spanish flu patents, as a little kid I got to hear about this stuff - entire villages wiped out by artillery fire, then chem agents.

Only ball powders are made in the USA - part of the manufacturing process is done underwater. Rifle ball powders have heavy deterrent coatings and need sparky primers like the Rem 7 1/2 (2303 kPA). Very fyne accuracy might be obtained with CCI450's & H4350 (Australia)

For ball powders I like Rem 7 1/2's

This attachment might be of interest -

Table 1 gives info - Rem 7 1/2's are real sparky - don't let stuff like kPA (kilo Pascals- unit of pressure - Pascal is 1 newton per 1 square meter) deter you from reading this. Newton is force needed to accelerate/move 1 kg mass 1 meter per second per second

My 6.5CM & 6CM run on a steady diet of Staball 6.5 & Rem 7 1/2's. The 6.5CM with max loads of R-S Hunter & 120's at 3,000 fps, approaches the famous .270 Win for practical results, like dead deers. Dependable results at temps under 30 F.

6.5 CM ammo having CCI 41's & RS Hunter exhibited wide swings of velocity and printed double groups at 300, like two 4-7 shot groups 4-5 inches apart at 300. Not to be used, especially in cold temps.

Extruded powders are no longer made in the USA - read about horrific explosions that devastated multi acres & busted windows 1/2 mile away when 10 or more tons of powder ignited during drying stage (solvents). WWI - machine gun & other stuff use - death & destruction ending with Spanish flu taking 1/2 mil more lives worldwide. A visit to the abandoned, sad, & desolate Belmont town cemetery in Montana has many graves of Spanish flu victims. One grave marks the life of a USN sailor who was "lost at sea" during the WWII battle of Okinawa. My grandparents were immigrants from France and served a strong woman who volunteered as a WWI battle field nurse then cared for Spanish flu patents, as a little kid I got to hear about this stuff - entire villages wiped out by artillery fire, then chem agents.

Only ball powders are made in the USA - part of the manufacturing process is done underwater. Rifle ball powders have heavy deterrent coatings and need sparky primers like the Rem 7 1/2 (2303 kPA). Very fyne accuracy might be obtained with CCI450's & H4350 (Australia)