I have a 10 twist 6mm AI and shoot the 87 Vmax at just under 3,500 fps using 50.5 grains of VN165. Accuracy is more than acceptable with 90% hits on pop can size rodents at ranges up to 400.

Going to to Ackey design fixed the slopey body 6mm Rem. I fire form cases using dried up coffey grounds & pistol powder. Despite its modest G1 BC of .4 the 87 Vmax does well up to 600 yards. An old 8 twist 6mm AI did well with the 95 grain Berger VLD at 3250 plus. The 6mm 95 Berger VLD has a low form factor (SD/G7BC) compared to other 6mm bullets and can be driven faster than 105's.

The latest & greatest 6mm bullet for rodents & such might be the Hornady 6mm 80 grain ELDVT. Running the Miller Sg calcs indicate marginal stability with a 10 twist but the bullet holes in paper indicate inadequate stability. The twist rate printed on the 80 grain ELDVT bullet box is 8 twist. The 80 ELDVT has a real low form factor compared to other & VLD type 6mm bullets.

Planned is a side by side ballistics contest between the 10 twist 6mm AL, 87 Vmax @ just under 3,500 fps & an 8 twist 6mm CM, 80 ELDVT at some 50-75 fps less velocity. Ranges will be up to 1,000.

The 6mm & 6.5 CM cases are similar to Ackley improved in regard to body taper & shoulder angle with very minor differences. A real big advantage with the 6 & 6.5 CM brass is availability & use of small rifle primers. Presently, I am buying once fired Federal 6.5 CM, small rifle primer brass for both 6 & 6.5 CM chambers with neck down for the 6mm & neck turning for both. Cheap $18 OTC Lee F/L dies, no expander/decap, are used for both 6 & 6.5 CM's, final neck sizing is done with Lee collet dies. Necks are turned to .268 OD for the 6mm & .289 for the 6.5mm.

Finding brass for the 6mm AI is a challenge. I have used PPU 7X57 brass with good results but with considerable effort including fire forming.

I might give up on the 6mm AI and re-barrel to a 6.5-06. I once had a 6.5-06 AI that shot 140's close to 3,000 & got hits on 1/2 gallon size rodents across an entire half section (880 yards). I used H1000 & the old 140 Sierra 6.5 GK bullet, 9 twist. The 6.5-06 AI might be a wasted effort as I now have a 8 twist 6.5 PRC but 6.5 PRC brass is pricy and velocity gains over the 6.5-06 are marginal.

Some 6mm AI pics

Shown is a 300 yard hit on mild steel (2.5 inch diameter) with the 6mm AI, 87 Vmax & finished round with anneal. It feeds perfectly thru a long action Ruger M77 MKII.

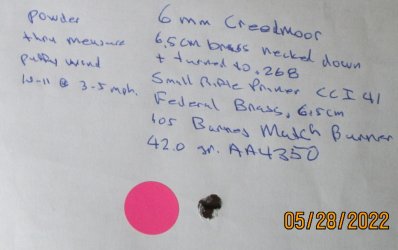

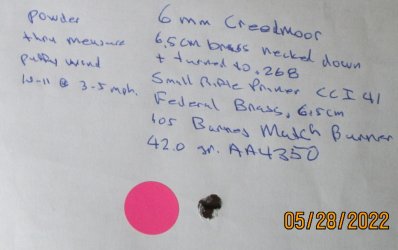

The competing 6mm CM is an accurate shooter and might be just as effective with less work & expense (5 shot group with easy & cheap components). I need to see this with the 80 ELDVT.