Leaf Litter

Well-Known Member

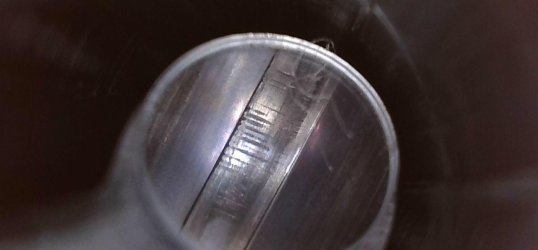

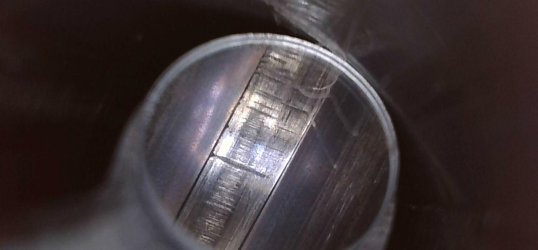

I purchased a used barrel and recently bore scoped it. What would cause these marks?

My only guesses were issues with the reamer at the factory or something being pushed in there to clear a squib?

My only guesses were issues with the reamer at the factory or something being pushed in there to clear a squib?

Attachments

Last edited: