lepcur1748

Well-Known Member

These are nice. Thank you!

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Just did this to estimate ANSI PSI to ANSI CUP and back. Wanted to estimate/convert Hodgdon 6.5X47 Lapua CUP load data to PSI.

Reference:

View attachment 251985View attachment 251986View attachment 251987

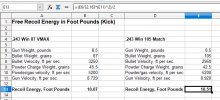

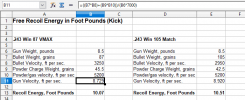

Thank you for sharing!I've built a couple of spreadsheets that I think are handy so I thought that I would share them with the reloading community here.

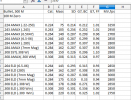

I use one for documenting my load when I use a chronograph. It calculates the following for a 1 to 10 shot group for 7 different loads:

Number of shots

Lowest velocity

Highest velocity

Average Velocity

ES

Energy in ft. lbs

SD (note- Standard Deviation is a statistical value. 10 data points is the least number recommended by most chronograph mfgs and a very small sample. Statisticians will tell you that SD is only as good as the number of samples and they generally wrinkle their nose at a sample as small as 10. If you have less than 10 data points the spreadsheet will still calculate a result but it's probably not of much value)

Just fill in the blanks that you can before you go to the range and add the velocity and atmospheric data once you get there and start shooting. I take a printed copy with me but it will load on to a PDA (I loaded it on my Dell Axim 50). Once you get home you can type in the recorded values and do file Save As and save a copy specific to a particular test.

I also use the sheet when I don't use a chronograph. It's handy for keeping track of what loads that I've tried. I also have columns to record atmospheric data as well as data about the load that I am testing (caliber, BC, powder, bullet, etc.). The spreadsheet is protected to prevent accidental over writing of a formula. If someone wants the password I will gladly give it out. For that matter, if Len wants to include it when he edits the post that's fine with me. Who knows, maybe someone will get froggy and change the calcs to handle a larger sample size

I use the other spreadsheet to give me an overview of what charges I will use for a specific cartridge. When I go to the loading bench all I take with me is one sheet of paper rather than the manual. Once the loads are built I put the printout into the cartridge box with notes on which row contains which load. This doesn't sound like it would be that handy but I list every powder that I have on hand and I have a tab for rifle and a tab for pistol. I know this is going to make some long time reloaders wince a little but we have a lot of new to reloading people out there (that's a good thing). By listing all of the rifle powders on one tab and all of the pistol powders on another the likelihood of accidentally loading a rifle powder in a pistol case or vice-versa should be diminished since the "recipe" is for a specific powder is right there. Another benefit is that I only have load info for the powders that I have on hand. I don't have to worry about weeding through all of the other data. I thought about breaking it into caliber specific tabs but decided it would be more useful to more people if I did it this way. To tweak it to your liking just remove the powders that you don't have and add the ones that you do.

If Len posts the sheets that I sent him then they will already have data points entered in a couple of columns. Just delete the blue and red colored info. BTW- I used red to indicate max or over max charges in.

Feedback is appreciated but not necessary.