chrishatley

Well-Known Member

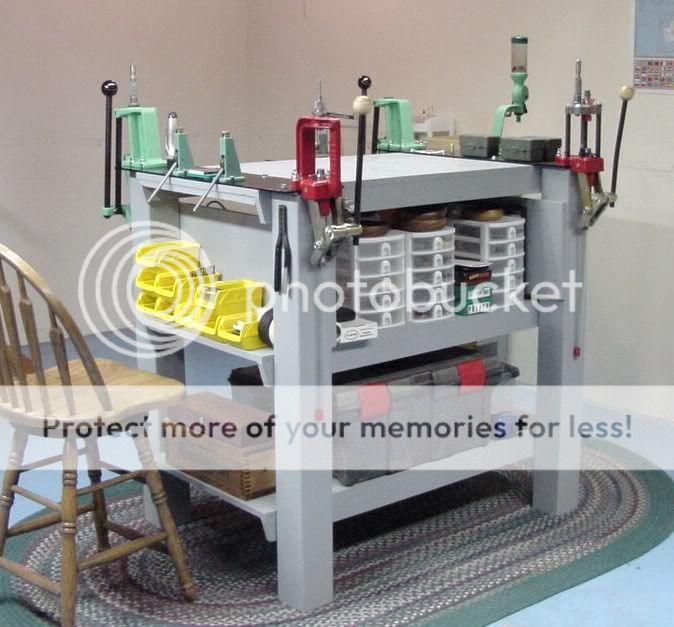

Timber, that is one hell of a nice bench man!

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

It will be epoxy coated like this, which is a matching desk for my office.

This is what I built. Free standing and hell bent for stout. The shelves measure 2' x 4' cut from a single sheet of 3/4 plywood reinforced with 5/4" boards glued and screwed. The uprights are the fake deck material 5.25" x 5.25" with a sheet of 5/16" steel plate straddling the legs. The remaining plywood sheet was cut for end braces, glued and screwed. I painted it with Stair and Floor paint (3 coats) that dried like iron. The presses are mounted directly over the legs and are rock solid.

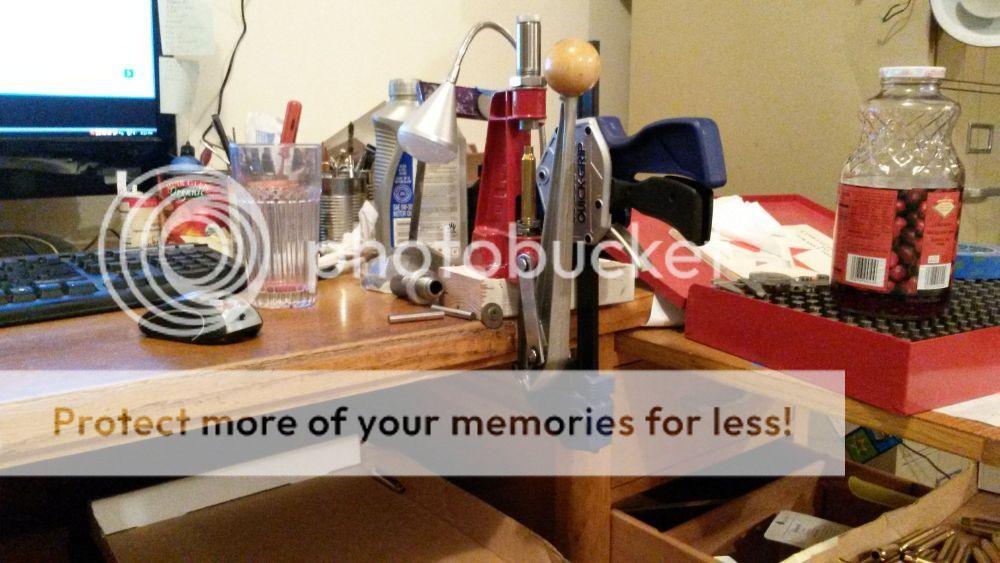

[/QUOTE]The pictures are few years old but I made mine mobile.