I have recently started using primer pocket gauges to check the brass after decapping and before sizing. I had to"retire" a lot of Federal brass from my 224 Valkyrie for loose pockets. I never had an issue with Lapua or ADG or Peterson brass. I also do not "hot rod" my loads since I mainly shoot benchrest. Loose prime pockets are indeed dangerous both to the equipment and the shooter.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Primer Seating?

- Thread starter Lefty57

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Like a swage on military rounds?

There is a tool to remove the swage but have not seen a tool to give it the swage like some I have seen on military rounds

Fired up the 1024 lathe, modified the large primer pocket swaging spud.

Set up in the press is the same as swaging operation.

Proving the concept. It works, take a closer look you can see the circular mark around the primer. I stop at this minimal testing till I heat treat the crimping edge. The knife edge may not last long. I also do not like the way the die centers the case. Too much slop for this application. In swaging it does not matter, the primer pocket aligns the case. My plan is to modify a neck sizer with the correct length swaging rod that goes inside the die that bears against the opposite side of the primer pocket.

My thinking the application is for the brass heading to the recycle bin to give it one last hoorah before discarding.

Thoughts?

I made a similar modification to the swaging stud and it works. Unfortunately, now I'm using an Zero press and the case stripper doesn't fit over the ram. I need to make an oversized case stripper when I need to do this again.

I bet you could make small rifle and large rifle swaging rods and make some money.

Great idea going through the case instead of the primer pocket.If you make a few I will buy a large rifle swaging rod

Great idea going through the case instead of the primer pocket.If you make a few I will buy a large rifle swaging rod

Thoughts?

When brass is done, it's done. The key is to perform proper work ahead of time to ensure it's not done too early in it's life and you get the use you want out of it.

This comes in the form of proper vetting of sizing dies, processes, and load pressures.

I won't knock your ingenuity however.

-----------

Follow on Instagram

Subscribe on YouTube

Amazon Affiliate

As an Amazon Associate we earn from qualifying purchases.

View attachment 386550

What is that? Case coming apart?

It is a junk brass from a batch someone generously gave me.

Mike Matteson

Well-Known Member

That's my understanding too. I haven't tried it yet but will be.The brass does'nt HAVE to be trashed if the pockets are loose. You can always set them on a ball bearing and strike the inside of the case with a punch directly over the flash hole. This will tighten the pocket.

When brass is done, it's done. The key is to perform proper work ahead of time to ensure it's not done too early in it's life and you get the use you want out of it.

This comes in the form of proper vetting of sizing dies, processes, and load pressures.

I won't knock your ingenuity however.

-----------

Follow on Instagram

Subscribe on YouTube

Amazon Affiliate

Thank you for the input, and the kind words.

As an Amazon Associate we earn from qualifying purchases.

Citified

Well-Known Member

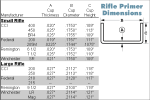

A while back, someone posted a chart that showed how primers of different brands are slightly different dimensionally. Sometimes switching to another brand of primer will solve this issue of loose fit. This assumes of course, you have a selection of various primers in lean times.

I couldn't find the post but someone can probably retrieve it.

I couldn't find the post but someone can probably retrieve it.

When I started with the 260 several years ago, I bought my buddies dies, a bunch of brass and bullets. While priming (CCI 200) I found some with loose pockets, at least looser than others. I started measuring and they were at the high end of the spec at .210". I wasn't comfortable with them, so I went through all of the brass and tossed anything that measured .210" or larger. They probably would've been fine, but not worth me taking a chance.

Justice1327

Well-Known Member

Might help

Attachments

-

5136C776-59E8-4AEB-A2D9-37949916FCB3.png71.1 KB · Views: 65

5136C776-59E8-4AEB-A2D9-37949916FCB3.png71.1 KB · Views: 65 -

A740A1EC-C273-4902-9C46-12B914941B5D.png105.5 KB · Views: 56

A740A1EC-C273-4902-9C46-12B914941B5D.png105.5 KB · Views: 56 -

0381F823-BD09-4ADB-A35D-AF6981395C6E.png117.3 KB · Views: 68

0381F823-BD09-4ADB-A35D-AF6981395C6E.png117.3 KB · Views: 68 -

A08B23A1-8F3D-4F81-BDC2-D6689F4AEF9F.png128.9 KB · Views: 62

A08B23A1-8F3D-4F81-BDC2-D6689F4AEF9F.png128.9 KB · Views: 62 -

09DA396E-A4CF-496D-9666-F088924AEB45.png113.7 KB · Views: 64

09DA396E-A4CF-496D-9666-F088924AEB45.png113.7 KB · Views: 64 -

634B50E0-BB82-405E-9CFD-632AE4EEE35A.png91.8 KB · Views: 61

634B50E0-BB82-405E-9CFD-632AE4EEE35A.png91.8 KB · Views: 61 -

915ADC31-F9DE-4513-B160-6F63CB60AB30.png7.4 KB · Views: 60

915ADC31-F9DE-4513-B160-6F63CB60AB30.png7.4 KB · Views: 60

Lenny Foffa

Well-Known Member

- Joined

- Mar 6, 2017

- Messages

- 1,686

I have had this issue from time to time. Starting withNew Winchester Brass, in 270 Win, Loaded in my Weatherby Ultralight. Using the RCBS Primer seating tool, I can really tell the difference between a properly seated Winchester LR primer, and the occasional one that just goes in Super easy . This may occur about the 4th or 5th loading of that same batch of matched Winchester cases, used in one specific rifle, with Winchester LR Primers. So I am really happy to be reading this thread, and I have sent for the Go/No-go gauges today. Loading for over 55 years , and STILL LEARNING!!!! By The way is there an Industry Spec for the Dia. of all Large Rifle/ Large Rifle Magnum Primers???Thank You all

Similar threads

- Replies

- 10

- Views

- 3K