Virgin brass is always smaller than a go-gauge, for what that's worth. You shouldn't have anything to worry about with CHS on the new brass. Keep in mind that ADG brass is on the thicker side so reduce your load and work up to safe pressure.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New 6.5 Creedmoor brass headspace seems a little short

- Thread starter Carey Farmer

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Starlite

Well-Known Member

Here are some photos of my alpha brass (same lot). New, fired, resized and in the COAL gauge perhaps not in the right order as I'm posting and viewing from my iPhone.Thank you Starlight. I don't really trust the absolute values I'm getting from my caliper, but I think the differences between fired brass and the new brass are probably good. Do you have a difference between your fired brass and your unfired brass?

Fired

Fired New

New gauge with fires brass

gauge with fires brass full length resize with 2 thou shoulder bumped back

full length resize with 2 thou shoulder bumped backStarlite

Well-Known Member

Forgot to mention. Not that it's super important as long as you're measuring from same POR but C.375 is the stated gauge for 6/6.5 (et al) creedmoor brass

Carey Farmer

Well-Known Member

Yep, looks like your new brass is 0.0055" shorter than your fired brass. That's pretty close to my 0.007".Here are some photos of my alpha brass (same lot). New, fired, resized and in the COAL gauge perhaps not in the right order as I'm posting and viewing from my iPhone. View attachment 372355FiredView attachment 372354NewView attachment 372353gauge with fires brassView attachment 372352full length resize with 2 thou shoulder bumped back

Carey Farmer

Well-Known Member

I got the .400 headspace reference diameter from SAAMI's website. Page 51 at this link: https://saami.org/wp-content/upload...99.4-CFR-Approved-2015-12-14-Posting-Copy.pdfForgot to mention. Not that it's super important as long as you're measuring from same POR but C.375 is the stated gauge for 6/6.5 (et al) creedmoor brass

Lefty G-gear

Well-Known Member

6.5 Creedmoor case gaugesPrepping to load some practice rounds in my 6.5 Creedmoor target rifle with brand new brass. Checked brass length with a .400" comparator, and was surprised at how short the new brass is - about 0.007" shorter than fired brass from that same rifle. Checked my "go" gauge and the new brass is .005" shorter than a "go" gauge. Pulled a bullet from a Hornady factory round and the new brass is .006" shorter than the unfired Hornady case.

Should I be worried about this much extra chamber headspace compared to new brass length causing case - head separation?

Usually new, non-belted brass is at most a couple thousandths shorter than my fired brass.

6.5 Creedmoor Rifle Gauges| Midsouth Shooters

XLR Industries

Well-Known Member

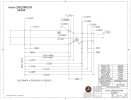

Here is a 6-creed reamer print. Everything should be the same as 6.5 except the neck diameter. The datum line should be in the same location which is the headspace line. Check the internal diameter of your gauge also if you compare the numbers directly!

Attachments

Lefty G-gear

Well-Known Member

Prepping to load some practice rounds in my 6.5 Creedmoor target rifle with brand new brass. Checked brass length with a .400" comparator, and was surprised at how short the new brass is - about 0.007" shorter than fired brass from that same rifle. Checked my "go" gauge and the new brass is .005" shorter than a "go" gauge. Pulled a bullet from a Hornady factory round and the new brass is .006" shorter than the unfired Hornady case.

Should I be worried about this much extra chamber headspace compared to new brass length causing case - head separation?

Usually new, non-belted brass is at most a couple thousandths shorter than my fired brass.

Three 5-rd. groups, at 1/2 -grain increments, or so.

Lefty G-gear

Well-Known Member

Oh. let us know if you sized the cases thru the die first, or not.Prepping to load some practice rounds in my 6.5 Creedmoor target rifle with brand new brass. Checked brass length with a .400" comparator, and was surprised at how short the new brass is - about 0.007" shorter than fired brass from that same rifle. Checked my "go" gauge and the new brass is .005" shorter than a "go" gauge. Pulled a bullet from a Hornady factory round and the new brass is .006" shorter than the unfired Hornady case.

Should I be worried about this much extra chamber headspace compared to new brass length causing case - head separation?

Usually new, non-belted brass is at most a couple thousandths shorter than my fired brass.

Some don't.

I'd size the new brass.

Measure EVERYTHING before n after with a caliper n case gauge.

Last edited:

I've been loading since'77, shot some benchrest back then and LE sniper work and still strive to be as precise as possible in my shooting / loading. A friend told me that he fireforms using a paper wad stuffed into the neck with whatever fast powder he has the most of and his results work for him. I have a 6.5-55 AI that I plan on trying his method. Still have to consume a primer and powder but no bullet. Just a possibility

Carey Farmer

Well-Known Member

Good point kgunz, a go-gauge wouldn't be very useful if manufacturers made their brass longer than the go-gauge. Starting to sound like most folks with more experience hand loading don't think .005" shorter than a go-gauge is a problem. Sure appreciate everyone's comments.Virgin brass is always smaller than a go-gauge, for what that's worth. You shouldn't have anything to worry about with CHS on the new brass. Keep in mind that ADG brass is on the thicker side so reduce your load and work up to safe pressure.

Still trying to reach someone at ADG. I'll let everyone know what they say.

Lefty, the dimensions I gave in the previous post were unsized cases right out of the box. I did subsequently full-length size them (to make sure the necks were straight and the bodies not oversize) but the die bottomed out against the shell holder before it hit the case shoulders.Oh. let us know if you sized the cases thru the die first, or not.

Some don't.

I'd size the new brass.

Measure EVERYTHING before n after with a caliper n case gauge.

Carey Farmer

Well-Known Member

Thanks osok. I guess I would have to neck up and then partially neck back down to create a false shoulder to make sure the case stayed snug against the bolt face? Hadn't really thought of going that route. But the fastest powder I have is the H4350 I bought for this chambering. I use H4831sc, H1000, or Retumbo in all of my other rifles.I've been loading since'77, shot some benchrest back then and LE sniper work and still strive to be as precise as possible in my shooting / loading. A friend told me that he fireforms using a paper wad stuffed into the neck with whatever fast powder he has the most of and his results work for him. I have a 6.5-55 AI that I plan on trying his method. Still have to consume a primer and powder but no bullet. Just a possibility

QuietTexan

Well-Known Member

I form cases with the false shoulder like you just described, but we're talking AI level of case movement there, not just the shoulders moving to fill the chamber. I shoot them, don't mess with COW. I shot a .300" group at 100 yards with fireforming loads, if it holds sub-MOA out to a reasonable distance there's no need to COW, the fireforming loads are more than accurate enough for me.I guess I would have to neck up and then partially neck back down to create a false shoulder to make sure the case stayed snug against the bolt face? Hadn't really thought of going that route

Carey Farmer

Well-Known Member

Thanks QT. I'm thinking I'll probably load these cases with a slight jam into the lands, and just go about my business.I form cases with the false shoulder like you just described, but we're talking AI level of case movement there, not just the shoulders moving to fill the chamber. I shoot them, don't mess with COW. I shot a .300" group at 100 yards with fireforming loads, if it holds sub-MOA out to a reasonable distance there's no need to COW, the fireforming loads are more than accurate enough for me.

Similar threads

- Replies

- 35

- Views

- 4K