You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Neck turning for a hunting rifle

- Thread starter Firearrow

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Firearrow

Well-Known Member

+1 on bullet concentricity and sorting brass for neck thickness, which is a major factor in a bullet seating straight. Keep brass with a neck variation of .001" or less. Strive to keep bullet runout at .005" and less with factory rifles

This is something that I can do. Now that I have some tolerences to work with, I know what look for. Thanks.

boomtube

Well-Known Member

" So the question goes, is neck turning a waist of time for a factory chambered hunting rilfe?:

Mostly it's fanning the wind. Few factory sporters are sufficently accurate for it do do much good. I do it anyway but.....??

"what is the distance you should be shooting, with what kinid of grouping, before neck turning will show any improvements?"

IF it's going to do any good you will see basically the same percentage of improvement at any range or group size.

Mostly it's fanning the wind. Few factory sporters are sufficently accurate for it do do much good. I do it anyway but.....??

"what is the distance you should be shooting, with what kinid of grouping, before neck turning will show any improvements?"

IF it's going to do any good you will see basically the same percentage of improvement at any range or group size.

Firearrow

Well-Known Member

" So the question goes, is neck turning a waist of time for a factory chambered hunting rilfe?:

Mostly it's fanning the wind. Few factory sporters are sufficently accurate for it do do much good. I do it anyway but.....??

"what is the distance you should be shooting, with what kinid of grouping, before neck turning will show any improvements?"

IF it's going to do any good you will see basically the same percentage of improvement at any range or group size.

Thanks for the help. Was not sure about the distance, and grouping.

paphil

Well-Known Member

First, you must think about the mechanics of what happens when you fire the bullet, then what happens when you resize the fired brass. Firing expands the brass to the full size of your chamber, not only the neck, but the entire case. If the neck were to thick, the shell wouldn't have chambered in the first place. Sizing down a case for wildcat sizes results in extra brass in the neck which usually must be removed in an amount that will give two to three thousandeths clearance on the finished cartridge. Sizing up to a larger size will thin the brass and usually won't require turning unless it is a custom chamber with tight tolerances, usually done for that very reason, to have enough brass to turn and still fit within that two to three thousandths tolerance on the completed shell. Turning will result in better concentricity but must not be done at the cost of making the finished neck fit loosley in the chamber. After firing , these loose necks will once again fireform and fit the chamber , but may not have enough neck tension to hold the bullet after resizing. Once I have my brass set for a certain gun, I necksize only and always check trim to length. A case that is too long is very bad for long range accuracy. Good luck!!

trailrider121

Well-Known Member

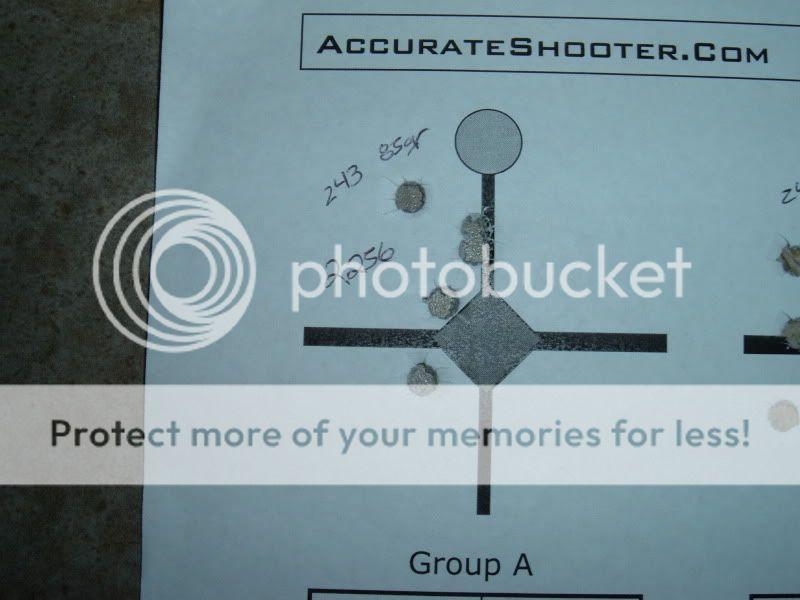

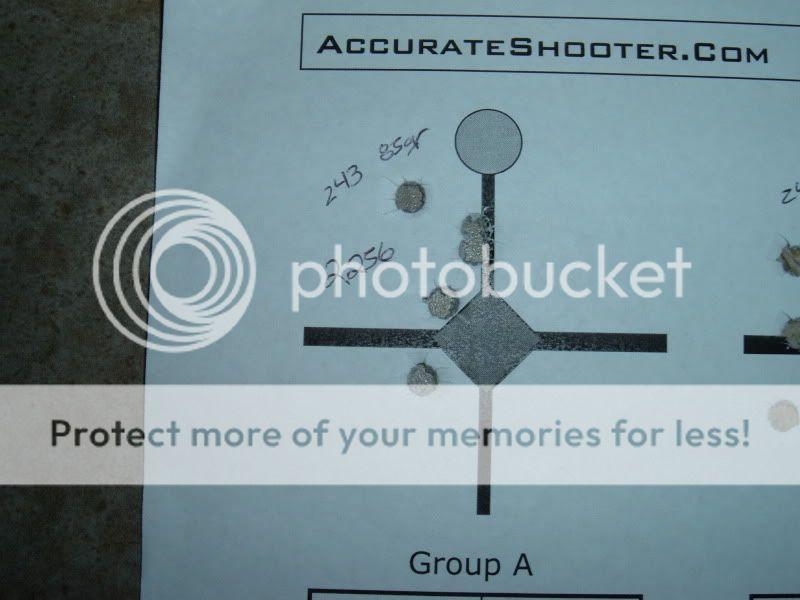

Factory barrel on Stevens 243 win 22" barrel 85 gr HPBT load. Bot targets 5 shot groups. It decreased group size by 25%.

Collet case / No neck turn.

same as above, but neck turned,just cleaned up high spots.

Collet case / No neck turn.

same as above, but neck turned,just cleaned up high spots.

Using Lapua or Norma brass, I don't feel the need to turn the necks.

Using Rem, Win or others I feel cleaning up the necks is needed to obtain the utmost accuracy. Neck thickness on this brass can vary significantly with thick and thin spots the norm. After you turn your first batch of this brass you will understand.

It will tighten up groups in an off the shelf hunting rifle.

Using Rem, Win or others I feel cleaning up the necks is needed to obtain the utmost accuracy. Neck thickness on this brass can vary significantly with thick and thin spots the norm. After you turn your first batch of this brass you will understand.

It will tighten up groups in an off the shelf hunting rifle.