Thanks for all the suggestions. Also forgot to mention these load are you using Peterson brass.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Neck tension

- Thread starter OFtrash

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

slikmrc

Well-Known Member

I was loading up some Tubbs lapping bullets in some nickel 300 WSM cases this morning. I'm seeing a very slight ring where the seating stem stops on the bullet. Don't see this with non coated bullets, this is telling me I need to polish the seating stem a little more I'm thinking. 10 bullets seated to with in .0025 so happy with that. Polishing seating stems with bore polish and cleaning dies on regular basis has helped in keeping seating lengths consistent.

I looked it up on Hodgdon reload manual. 79.4 max powder WLRMP. So you are right in there on amount of powder in your case. Are you using a drop tube and tapping the side of the cases to compact the powder load? The drop tube funnel and tapping the sides of your case will help settle the powder in the case. The ogive isn't always the same from bullet to bullet. So you'll need a comparator to check the differents on where the ogive is or changes in there length. Have you done a ladder test on set back from bullet to lands to compare the grouping yet.I tried a search with no results. Im currently working up a load for a M70 SG in 300WM. Im using H1000 and 180 Accubonds. What Im seeing is inconsistent BTOG that I believe is due to a compressed load of 79.5 grains.Im seeing between .004 and .006 difference in BTOG. Im currently running about .002 of neck tension. For those that are more knowledgeable Im wondering if thats a concern or if I need to increase neck tension to hold things in check. Ive have not tried these for accuracy to see if there is actually a concern due to the current supply shortages.

Yeah, just shake your powder down in the brass. Can you an electric toothbrush as suggested above, or just shake on the benchtop with your hand. A few light vibratory taps and you can get it down 5%

A drop tube will be the next thing I try. Im getting really good ES and SDs with this load but the accuracy isn't quite where I would like it to be but I think I may be having an issue with the scope. So my next trip out I'm gonna try the drop tube for the CTOG inconsistency and try a different scope for the accuracy. The scope is a leupold factory blemished scope so I have my doubts on it.I looked it up on Hodgdon reload manual. 79.4 max powder WLRMP. So you are right in there on amount of powder in your case. Are you using a drop tube and tapping the side of the cases to compact the powder load? The drop tube funnel and tapping the sides of your case will help settle the powder in the case. The ogive isn't always the same from bullet to bullet. So you'll need a comparator to check the differents on where the ogive is or changes in there length. Have you done a ladder test on set back from bullet to lands to compare the grouping yet.

MagnumManiac

Well-Known Member

I run 81g of H1000 behind 180g Ballistic tips or Accubonds without any issues in one of my 300WM's from a compressed load. I also run 81g of RL25 behind 180g Accubonds, but these rifles are running 3.6" mag boxes. I found my Kimber (3.4" mag) could run 80g H1000 with 180g Accubonds without issue.

I don't think your slight compression is causing this.

Cheers.

I don't think your slight compression is causing this.

Cheers.

I didn't see anything on bullets to lands distance or setback. Like I say I don't have a 300WM. I would be working on that at the same time. Adjust your jump to lands, and see where that gets you. It's comes together.

I tried a search with no results. Im currently working up a load for a M70 SG in 300WM. Im using H1000 and 180 Accubonds. What Im seeing is inconsistent BTOG that I believe is due to a compressed load of 79.5 grains.Im seeing between .004 and .006 difference in BTOG. Im currently running about .002 of neck tension. For those that are more knowledgeable Im wondering if thats a concern or if I need to increase neck tension to hold things in check. Ive have not tried these for accuracy to see if there is actually a concern due to the current supply shortages.

I tried to post the link, but I got the error above. Go to YouTube and type "seating depth inconsistencies, select Q&A - Why Do Seating Depths Vary?

https://www.youtube.com/results?search_query=seating+depth+inconsistencies

Last edited:

Upsidedownjack

Well-Known Member

- Joined

- Dec 28, 2017

- Messages

- 316

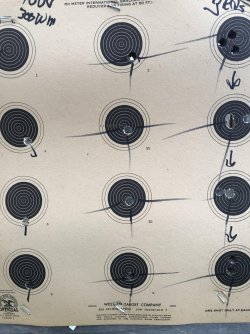

HMR-PRO. 300 WM. Small bore 50 yd reduced for shooting at 50 Feet. SHOT AT 100 yds. Just breaking in. Less than 100 rds down range! Much better NOW!I tried a search with no results. Im currently working up a load for a M70 SG in 300WM. Im using H1000 and 180 Accubonds. What Im seeing is inconsistent BTOG that I believe is due to a compressed load of 79.5 grains.Im seeing between .004 and .006 difference in BTOG. Im currently running about .002 of neck tension. For those that are more knowledgeable Im wondering if thats a concern or if I need to increase neck tension to hold things in check. Ive have not tried these for accuracy to see if there is actually a concern due to the current supply shortages.

79.5 gr H-1000, 180 gr SST! This load has Always worked for me. Not my first 300wm. But this is the Best Shooter, so far!

Attachments

I use 72@IMR4350 in mine for 180's.I tried a search with no results. Im currently working up a load for a M70 SG in 300WM. Im using H1000 and 180 Accubonds. What Im seeing is inconsistent BTOG that I believe is due to a compressed load of 79.5 grains.Im seeing between .004 and .006 difference in BTOG. Im currently running about .002 of neck tension. For those that are more knowledgeable Im wondering if thats a concern or if I need to increase neck tension to hold things in check. Ive have not tried these for accuracy to see if there is actually a concern due to the current supply shortages.

Exactly.Using a drop tube and pouring powder slow when dropping the charge helps greatly on compressed loads.

I run 81.0 gr of H1000 in my .300WM My COAL is long, 3.585 I think. It's a lot of powder to cram in there.

I use a drop tube and pour the powder in the funnel at an angle so that the powder swirls around the funnel and down the tube. The powder settles better and takes up less space. I've heard it called "swirl charging" before. Don't remember where I heard about it. I have also lightly rested a whole tray of charged cases to the top of my vibratory case cleaner and settled the powder charges, that works too.

For me it makes the difference between crunching the powder and just barely compressing it enough that if you shake the loaded round you can't hear the powder rattle. To me that's just right.

Before I knew about this method I used to crunch the powder when seating bullets, then taper crimp to keep them in place. Shot fine, but I haven't bothered crimping since I've been giving them a swirly.

Last edited: