Black Tail Hunter

Well-Known Member

Hey Fellas,

When I try to remove my muzzle brake to clean it and my barrel it is a huge pain in the rear. I built a strap type wrench but it wont grip tight enough most of the time to remove. I usually end up wrapping it with a piece of material and using channel locks which has left some marks on it.

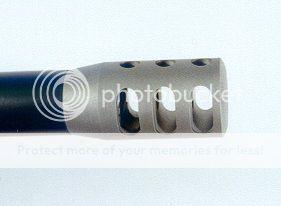

Is there a better way to do this, also is anyone familliar with this type of brake as far as who may have manufactured it? Sorry for the low res photo.

When I try to remove my muzzle brake to clean it and my barrel it is a huge pain in the rear. I built a strap type wrench but it wont grip tight enough most of the time to remove. I usually end up wrapping it with a piece of material and using channel locks which has left some marks on it.

Is there a better way to do this, also is anyone familliar with this type of brake as far as who may have manufactured it? Sorry for the low res photo.