Thank you, I must admit I did run it through a planer to get the bulk of the material off of the sides but all the rest was rasps, files and sand paper. It took me 40 hr. to completely get it fitted and finished. I have been working on firearms most of my life but only started making them in 2015, I have built 14 firearms completely from scratch since then, the last one in January of this year was a 9mm semi auto pistol, and all without any formal training all self taught skills. Thanks again for all the complements.You have every right to be proud, Ray! It's a project not many could or would complete. Time consuming set-ups and then hand fitting. And, there is no "drop-in" stock for that metal. Had to be made from a blank, not 'turned' on a duplicator and then fit.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More info about my 45-70 Home Build.

- Thread starter Ray Fryar

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

It's great to see someone build for themselves, I grew up with the american rifleman being full of advice for sporterizing all the old military bol;t guns and how to make your Garand shoot for highpower and many other things to build instead of buy. Now the new shooters can't put scope bases on without a gunsmith

wwbrown

Well-Known Member

Beautiful work thanks for sharing your masterpieces.

Thank you all, you are making my head swell. I have just made them for me and haven't shared them much except with family. Here are a couple more that I have built, the dark stock is my 224 Valkyrie I made for long range target shooting and the blond stock is a 17 Hornet. They are of the Chicopee design in the De Hass book but heavily modified for strength and to fit in a 1 piece stock. thanks to all and everyone have a Merry Christmas.Beautiful work thanks for sharing your masterpieces.

Attachments

Last edited:

Backwoods towny

Well-Known Member

Wow. Thank you for sharing

Merry Christmas

Merry Christmas

Amazing. That's pretty cool.

I would try that but the people that live in my town would complain about the shortage of duct tape and super glue in stores.

I would try that but the people that live in my town would complain about the shortage of duct tape and super glue in stores.

Harry Knutz

Well-Known Member

Wow Ray! That is awesome, Even more awesome that you were able to accomplish these on a Smithy. Smithy should give you their top model for letting them show your project and what can be done on one. I am sure the setups took hours longer due to blocking up for the right heights of the workpieces and work arounds that aren't necessary on individual units. I have conventional lathes and a Bridgeport clone and have never used a Smithy. That looks like one of their earlier models too! Quite impressive!

I don't have the talent you do either, Great job on that single shot and engraving! Thanks for sharing! HK

I don't have the talent you do either, Great job on that single shot and engraving! Thanks for sharing! HK

Wow!!! Very impressive!

wvbearhunter

Well-Known Member

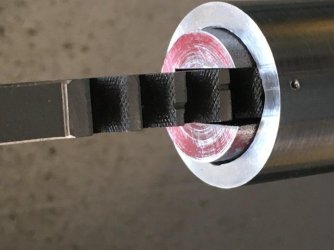

I have never seen a lock up like that, pretty cool

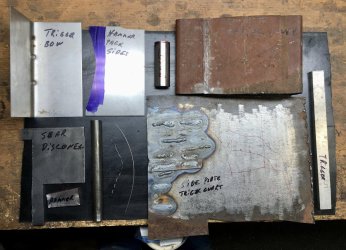

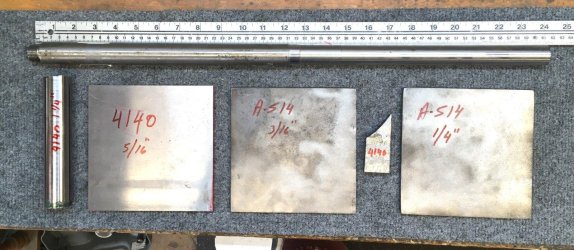

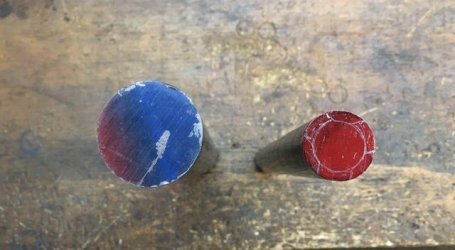

They are all DeHaas designs that I have modified heavily. Here is one more of a different design. The first picture is 2 12" pieces of 4140 pre-hard round stock 1" round and the other 1 1/2" round. The barrel was a 1 1/2" x 28" cylinder blank and I contoured it to a straight taper from 1 1/16" to .768 at the muzzle. The stock is a Boyd's un-inletted blank.

Attachments

-

A5A257DF-475F-4A01-A458-3289EE4600DF.jpeg51.6 KB · Views: 45

A5A257DF-475F-4A01-A458-3289EE4600DF.jpeg51.6 KB · Views: 45 -

D221CC48-8382-4477-A3D1-96E2FFC567DD.jpeg33.1 KB · Views: 44

D221CC48-8382-4477-A3D1-96E2FFC567DD.jpeg33.1 KB · Views: 44 -

68F6A6A1-7CDA-4152-8997-66712E13817F.jpeg29.5 KB · Views: 46

68F6A6A1-7CDA-4152-8997-66712E13817F.jpeg29.5 KB · Views: 46 -

1CDAD332-01B8-47CA-BCD4-17EAF6BF5842.jpeg42.2 KB · Views: 45

1CDAD332-01B8-47CA-BCD4-17EAF6BF5842.jpeg42.2 KB · Views: 45 -

D1D2AB97-4F8A-48FE-886F-6FE93448435A.jpeg27.4 KB · Views: 41

D1D2AB97-4F8A-48FE-886F-6FE93448435A.jpeg27.4 KB · Views: 41 -

2E58CB93-F9EF-4B97-912C-D9ED9623803C.jpeg12.7 KB · Views: 48

2E58CB93-F9EF-4B97-912C-D9ED9623803C.jpeg12.7 KB · Views: 48

I am always in awe of anyone with the craftsmanship skills like this. It's a gift that just keeps giving with such beautiful "works of art"! Heck I am not allowed to pick up a hammer!!!

Did you have any of the components heat treated?More Pictures.

Primarily the receiver, I'm curious I'm a 50 year toolmaker getting ready to retire but I want one more project to do before I leave my company

I have all the equipment to do it

Also you did a fine job very impressive

shortgrass

Well-Known Member

In his first post, that started this thread, Ray says he used pre-hardened 4140.Did you have any of the components heat treated?

Primarily the receiver, I'm curious I'm a 50 year toolmaker getting ready to retire but I want one more project to do before I leave my company

I have all the equipment to do it

Also you did a fine job very impressive

Similar threads

Recent Posts

-

-

-

-

-

Interesting video on what we all know is going on with automobiles

- Latest: comfisherman