Rifleman97

Well-Known Member

- Joined

- Dec 28, 2017

- Messages

- 402

I'm a woodworker by profession, I've got access through my work to just about any tool you can imagine for woodworking. I've decided I want to make a stock similar-ish to the manners EH1A. Fully adjustable wood stock, and I want to put mercury recoil tubes in it to counter balance and reduce recoil for the heavy magnum it'll eventually be used on. This is a long term project as I can't afford a whole gun build at the moment, but I do have plenty of wood to choose from.

Questions:

1. Does anyone know where I can find a good 3D model of a Remington 700 inlet? If I can find one I can potentially cut the inlet with a CNC.

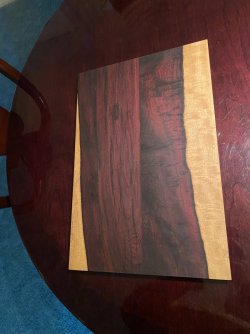

2. What wood species should I use? I don't have any French walnut or anything but I have some highly figured walnut, maple, or what I was thinking… Katalox heartwood for a gorgeous dark purple (Katalox cutting board I made pictured below) which extremely heavy but more durable than anything else you could reasonably buy.

3. Make the stock for my length of pull? Or make it short and have adjustable length of pull in case I ever decide to sell it?

4. Where would I find good hardware for the adjustment mechanisms in the stock?

I was inspired by the turnbull AR-15 and AR-10's with the really nice wood stocks.

Questions:

1. Does anyone know where I can find a good 3D model of a Remington 700 inlet? If I can find one I can potentially cut the inlet with a CNC.

2. What wood species should I use? I don't have any French walnut or anything but I have some highly figured walnut, maple, or what I was thinking… Katalox heartwood for a gorgeous dark purple (Katalox cutting board I made pictured below) which extremely heavy but more durable than anything else you could reasonably buy.

3. Make the stock for my length of pull? Or make it short and have adjustable length of pull in case I ever decide to sell it?

4. Where would I find good hardware for the adjustment mechanisms in the stock?

I was inspired by the turnbull AR-15 and AR-10's with the really nice wood stocks.