Steve's Opening Reminders:

The Hammer Hunter line is our long range or high bc line of bullets. This was the original line of bullets. These bullets all have 1.5mm hollow point and are typically 60%-70% weight retention. There is no drop off in terminal performance from the Shock Hammers. The only difference that we see on game is the Shock Hammer will open up slightly quicker. As time goes on we are learning that the extra shed weight of the Hammer Hunter is great aid in terminal performance with the several larger shed petals creating their own wound channels around the main retained shank wound channel. We designed the Hammer Hunter with the 1.5mm hp as it was the smallest that we could get reliable expansion. We tried 1mm hp but it would not always do what we wanted on game. Failure is not an option.

Our loading procedure: Always load with caution and never start with a stated max load from anyone or anywhere.

A reputable ammunition loading manual should be consulted for load development using a particular powder. Always follow good loading practices outlined in your loading manual. Our PDR design will tend to have less pressure due to less bearing surface contact with the bore. We recommend looking for a powder showing fairly high load density for similar weight bullets, but not compressed. We like to use powders that show a 90-95% load density with conventional bullets of the same weight. This will leave some room for the longer copper bullet and for the lower pressure possibly needing a bit more powder to get to pressure. We also recommend using a magnum primer to start ignition more quickly in order to seal the chamber as the bullet enters the bore. This is more important with larger cartridges and definitely magnum cartridges. Use of a chronograph to watch muzzle velocity compared to similar weight bullet velocity listed in loading manual will aid in load development. Muzzle velocity should not exceed max load velocity listed for similar weight bullets listed in loading manual. Muzzle velocity is an indication of pressure. Always watch for known pressure indicators such as heavy bolt lift or ejector marks on brass as well. We have found that Hammer Bullets are not sensitive to seating depth. Seating to mag length for repeating rifles or just off the lands will generally work very well without need to adjust for better accuracy. If we can reach the lands we like 20 thou off as a starting point.

Load development should be easy. Find your seating depth, choose your powder and primer, use start load data and work up your load to desired velocity, sight it in, and have fun hitting it with a Hammer.

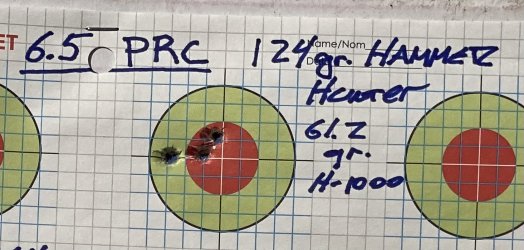

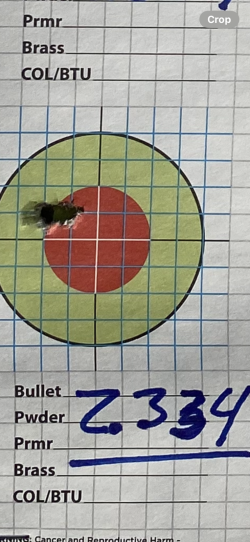

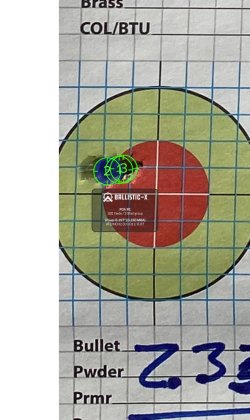

OK, here is the Hammer Hunter Load Data I have.

Please review your loads. There is a bit of needed info missing

***NOTE: THE HAMMER HUNTER DATA HAS GOTTEN SO LARGE IT IS NOW SPLIT INTO TWO DATA SHEETS.

Post 10/3/2024

G