I agree.

What I've learned in many forum years is that there are truly few truths in reloading.

Even common notions rarely pass tests across the boards.

I guess I didn't keep record of my past H20 testing,, which is frustrating.

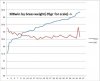

I searched around a bit and found an old BRC thread where a shooter posted his findings with (45) 308WW cases. It appears to me that he did a pretty good job, and so I graphed his results.

To chart correlation in scale, I subtracted 95gr from all brass weights while leaving H20 raw.

He has decent capacity variance for the cartridge, .5grH20, which would theoretically contribute 12fps spread in this cartridge. The brass weight itself varying 1.5gr. He could pick a mean in brass weight, or capacity, and it looks to me like he would end up with about the same number of cases(~30,30). If he chose 30 matching in capacity, his brass weight would not match & vice versa.

It would be very interesting to see other tests like this, with other cartridges.

Different results from different people are the reason that opinions vary on what's best or what is a good method.

Being a stickler for details and end results I compared all of the different methods and settled on one that was beneficial but could be done in a timely manner. At the time I was shooting competition

and burning up 400 to 500 rounds a week. so time was an issue.

Lots of my competitors would tell me this was a waste of time and that was a waste of time, and all you had to do was shoot a lot(Practice) to win.(Most would not tell there secrets because they wanted to win and thought if they divulged anything you would become there competition.

So I believed nothing I heard and only half of what I saw, and started testing every aspect to see

what made a difference and what didn't.

One of these things was volume testing of the cases. Here is what I found.

I started testing for consistency in one case with water and found that It was not consistent because the water needed to be treated. I would add water to the case and weigh it, then empty it and dry

it and allow it to reach ambient temperature and fill it again. armed with these results, I started trying different additives to the water and found the best consistency/results was with a wetting agent and de-mineralized water. This was a pain and having to mix chemicals with water was an

issue. so I tried other liquids. different oils, solvents and even paint thinners. all worked but had there own problems.

Next I tried to use different powders to check for volume and found this was inconsistent also. I found the best results using the finest/smallest Ball powder available but it would rarely repeat

using the same case.

Weighing was another method I experimented with and found its strengths and weaknesses.

I found that all cases had to be sized or fire formed, trimmed (Very precisely to length) and

the flash hole de-burred inside and cleaned well to have any hope of consistency. NOTE: this was necessary on all other methods tried also.

What I found with all of this was. NOTHING WAS PERFICT and the choice was mine on which way I wanted to go.

I did prove to myself that consistency in volume made a difference in SDs and ultimately accuracy if everything else was done correctly in the loading process.

So IMO the method is not as important as the quality of your process and the fact that you want better results and are willing to doo all of the other things required to improve your accuracy.

The best Smith and equipment in the world cant help poor ammo and vise versa.

J E CUSTOM