You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon Fiber Wrapped Barrels

- Thread starter 30 Caliber Mag Fan

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Sendero_Man

Well-Known Member

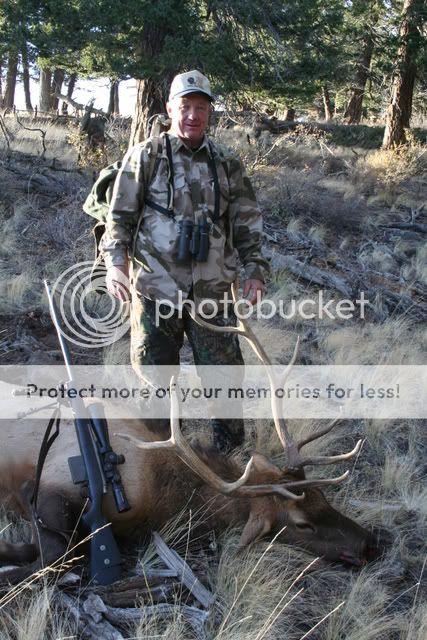

I have an ABS wrapped Rock liner that George with Precision Shooting built me.

you have seen my hunting posts and Antelope video with Tyler.

It is a shooter for sure.

I use it as a hunting rifle, not a paper puncher.

10.5 lbs scoped with NF NXS is great !

PM with any questions....

you have seen my hunting posts and Antelope video with Tyler.

It is a shooter for sure.

I use it as a hunting rifle, not a paper puncher.

10.5 lbs scoped with NF NXS is great !

PM with any questions....

Michael Eichele

Well-Known Member

I have a saying. I will try anything once.

Recently I tried an ABS barrel. I am still forming an opinion about it. I will say that so far it has shown alot of promise. My rifle was 16# and it is now between 12-13# with the same contour and similar length. I shot my best 300 yard group with it today. Using 200 ACCUBONDS shot a 1.187" 3 shot group. It has shot several sub .5 MOA groups at 300 yards. and a butt load just over .5 MOA in the .60 to .65 range. It seems as if heat moves to the surface fairly quickly. I dont think these trap heat as bad as the Christinsen barrels do. Christensen barrels are made to be light and nothing else. They are more of a novelty if you ask me. A neat concept more or less. Plus Shillen barrels (IMHO) suck. At least the ones available to you and me.

ABS barrels may be a better product than the competition but trying to get one inside 1-2 years is difficult at best and cost a small fortune. I am not sure they are the answer either. I know Mike D. told me he thought an ABS barrel in 300 RUM should last about 3000 rounds. I know a guy with 1000 rounds and is definatly showing signs of wearing out.

I think we will be seeing some cool new barrel designs within the next 10 years.

Recently I tried an ABS barrel. I am still forming an opinion about it. I will say that so far it has shown alot of promise. My rifle was 16# and it is now between 12-13# with the same contour and similar length. I shot my best 300 yard group with it today. Using 200 ACCUBONDS shot a 1.187" 3 shot group. It has shot several sub .5 MOA groups at 300 yards. and a butt load just over .5 MOA in the .60 to .65 range. It seems as if heat moves to the surface fairly quickly. I dont think these trap heat as bad as the Christinsen barrels do. Christensen barrels are made to be light and nothing else. They are more of a novelty if you ask me. A neat concept more or less. Plus Shillen barrels (IMHO) suck. At least the ones available to you and me.

ABS barrels may be a better product than the competition but trying to get one inside 1-2 years is difficult at best and cost a small fortune. I am not sure they are the answer either. I know Mike D. told me he thought an ABS barrel in 300 RUM should last about 3000 rounds. I know a guy with 1000 rounds and is definatly showing signs of wearing out.

I think we will be seeing some cool new barrel designs within the next 10 years.

Jeff In TX

Well-Known Member

Carbon Fiber is a fantastic insulator the previous carbon wrap barrels didn't fair all that well. I've heard nothing but great things about ABS barrels expect their lead times. My question is how did they change the physics of carbon wrapping process? How do they dissipate the heat from the barrel and not insulate it or keep it in.

tjonh2001

Well-Known Member

OK i am having nate form ssg build me a carbon fiber gun. i was giong to use a remington action in 300 rum. a 26in abs barrel and a lone wolf stock. after talking to all of these guys we have added the weight and it come to 5lb15oz with the muzzle break.

i want to know if you guys have heard that ABS has bad barrels. i need to know we are ordering my barrel this week. as you all know lead time is slow.....

i want to know if you guys have heard that ABS has bad barrels. i need to know we are ordering my barrel this week. as you all know lead time is slow.....

Black Diamond 408

Well-Known Member

Jeff,

Only one person knows for sure how the ABS system works, that is the owner of the company

Mike Degerness. It is a patented system and way different than Christensen arms.

I suspect it has a lot to do with the type of epoxy he uses for the bonding agent, you know there are many types out there, some are heat conducting. Its just a guess on my part. I toured his shop several years ago and didnt ask him any of the particulars of his process. I have installed many of his barrels and ALL of them are tac drivers. They do as advertised.

Dave

Only one person knows for sure how the ABS system works, that is the owner of the company

Mike Degerness. It is a patented system and way different than Christensen arms.

I suspect it has a lot to do with the type of epoxy he uses for the bonding agent, you know there are many types out there, some are heat conducting. Its just a guess on my part. I toured his shop several years ago and didnt ask him any of the particulars of his process. I have installed many of his barrels and ALL of them are tac drivers. They do as advertised.

Dave

James Jones

Well-Known Member

- Joined

- Jul 1, 2002

- Messages

- 2,854

Dave maybe you could answer wioth some sort of accuracy about how long the lead times are for a barrel seeing that you use alot of them? I have given them alot of thought , both ordering one outright and sending him a Bartlein blank turned to his specs.

Black Diamond 408

Well-Known Member

James,

He runs the wrapping in lots, it depends when you get your barrel into the shop. He might be running military barrels and or contract jobs. He then will run civilan orders in one group. So i cant really say for sure his lead time. My 416 barrel i had done took about 4 weeks as he was just finishing up a contract and the civilian orders was about to start. I have had it take up to 4 months but that was when he was doing it all by himself, now he has hired several workers and he said that it has speeded up the lead times. Best is to try and contact him and see what is currently going on in his shop. The best way is to have the blank made to his specs and send that to him so he dont have to do any ordering as that all takes extra time on his end. I had Benchmark make my last barrel for the wrapping, it turned out great and light. It is 1.450 breech tapered to 1.200 muzzle 32" The barrel was 6.5# I used a Titainum muzzle cap as Stainless is a standard item. I wanted to keep as much weight down as possible. The real weight reduction is the steel liner, it needs to be as light as possible. There is only about 8 ounces of Carbon wrapped onto the barrel, so that will give you an idea on what the barrel will turn out to be. Once he gets the barrel blank, he still has to do some contouring of the breech end and thread the muzzle for the cap. After the barrel is wrapped (looks like a bunch of thread and goop) it is cured in an oven for an extended time, then it goes to the CNC grinding machine to put on the taper. I had Lawton make me two blanks for the 338cal, Barney sent them to me unlapped and wanted them back after the process was done, both of these are super shooters(5# barrels), dont know if it made a difference or not when the lapping was done. I have had Rock, Lawton and BenchMark, all have been super shooters. I had one Rock that turned out on the heavy side, the liner must of been a bit larger (7.5#). When i was in his shop i picked up a 50BMG barrel and it couldnt of been much more than 8#, was going on some mil spec test rifle.

I havent talked with Mike in a few months so im not sure what his current times are.

It is worth the wait if your building a specialty rifle.

Dave

He runs the wrapping in lots, it depends when you get your barrel into the shop. He might be running military barrels and or contract jobs. He then will run civilan orders in one group. So i cant really say for sure his lead time. My 416 barrel i had done took about 4 weeks as he was just finishing up a contract and the civilian orders was about to start. I have had it take up to 4 months but that was when he was doing it all by himself, now he has hired several workers and he said that it has speeded up the lead times. Best is to try and contact him and see what is currently going on in his shop. The best way is to have the blank made to his specs and send that to him so he dont have to do any ordering as that all takes extra time on his end. I had Benchmark make my last barrel for the wrapping, it turned out great and light. It is 1.450 breech tapered to 1.200 muzzle 32" The barrel was 6.5# I used a Titainum muzzle cap as Stainless is a standard item. I wanted to keep as much weight down as possible. The real weight reduction is the steel liner, it needs to be as light as possible. There is only about 8 ounces of Carbon wrapped onto the barrel, so that will give you an idea on what the barrel will turn out to be. Once he gets the barrel blank, he still has to do some contouring of the breech end and thread the muzzle for the cap. After the barrel is wrapped (looks like a bunch of thread and goop) it is cured in an oven for an extended time, then it goes to the CNC grinding machine to put on the taper. I had Lawton make me two blanks for the 338cal, Barney sent them to me unlapped and wanted them back after the process was done, both of these are super shooters(5# barrels), dont know if it made a difference or not when the lapping was done. I have had Rock, Lawton and BenchMark, all have been super shooters. I had one Rock that turned out on the heavy side, the liner must of been a bit larger (7.5#). When i was in his shop i picked up a 50BMG barrel and it couldnt of been much more than 8#, was going on some mil spec test rifle.

I havent talked with Mike in a few months so im not sure what his current times are.

It is worth the wait if your building a specialty rifle.

Dave

Sendero_Man

Well-Known Member

Is ABS still in Lincoln ?

Black Diamond 408

Well-Known Member

Yes they are still in Lincoln Ne.

Colcalcipherol

Well-Known Member

- Joined

- Nov 16, 2012

- Messages

- 66

Finally there is a topic where I can make a legitimate contribution. I'm a PhD physical chemist with considerable experience and knowledge in thermodynamics. There is some debate over whether the carbon wrapping insulates or helps to cool a barrel. These wrappings are made of a very, very interesting, graphene- or graphite-like material consists of highly ordered carbon atoms. The high degree of ordering enables enhanced thermal conductivity by means of phonon transport which is the vibration of a lattice. Image several pool balls aligned perfectly on a table at short distances (say two inches apart). A person who is a decent shot can put energy into the que ball and transfer it down the line to the last ball which takes off at nearly the same speed as the incident que ball (and in the same line if everything is perfectly aligned). In the carbon fibers, the carbon atoms align in such a way that thermal energy can pass through the material via intermolecular collisions (like the pool balls) due to the extremely high order—which basically means that they are just lined up in the perfect manner. Let me give you some numbers: the thermal conductivity of carbon steel is 36-54 W/m/K while stainless steel is 16.3-24 W/m/K. You'll notice that it takes stainless a little longer to cool than carbon steel—this is why. These fibers, constructed of carbon nanotubes, have a thermal conductivity of 3180-3500 W/m/K! So, you can see that they are not insulators and that they will conduct heat very, very well.

I am having a .375 CheyTac built and I have asked my smith to use a Proof Research (ABS) carbon wrapped barrel. I'll report back after I have put her through the paces.

I am having a .375 CheyTac built and I have asked my smith to use a Proof Research (ABS) carbon wrapped barrel. I'll report back after I have put her through the paces.

Colcalcipherol

Well-Known Member

- Joined

- Nov 16, 2012

- Messages

- 66

Dave,

Have you noticed any difference in barrel life with the wrapped barrels? I am desperately hoping that they are considerably extended . . .

Have you noticed any difference in barrel life with the wrapped barrels? I am desperately hoping that they are considerably extended . . .

bruce_ventura

Well-Known Member

By now you've probably discovered that the thermal conductivity of carbon fiber composites used to wrap barrels is much lower than bare fiber - by a factor of about 100. I checked published data and found the through-the-thickness thermal conductivity at 400 K to be about 1-20 W/m-K, depending on the matrix and process, which is indeed much lower than barrel steel. Unless ABS has made a breakthrough in carbon-carbon technology, these materials are definitely insulators compared to normal barrel steel....In the carbon fibers, the carbon atoms align in such a way that thermal energy can pass through the material via intermolecular collisions (like the pool balls) due to the extremely high order—which basically means that they are just lined up in the perfect manner. Let me give you some numbers: the thermal conductivity of carbon steel is 36-54 W/m/K while stainless steel is 16.3-24 W/m/K. You'll notice that it takes stainless a little longer to cool than carbon steel—this is why. These fibers, constructed of carbon nanotubes, have a thermal conductivity of 3180-3500 W/m/K! So, you can see that they are not insulators and that they will conduct heat very, very well.

I am having a .375 CheyTac built and I have asked my smith to use a Proof Research (ABS) carbon wrapped barrel. I'll report back after I have put her through the paces.

I don't have an answer to your question about barrel life, but I'm guessing it depends a lot on the rate of fire. If you allow the barrel to cool between shots, I think it should be similar to a conventional barrel.

Colcalcipherol

Well-Known Member

- Joined

- Nov 16, 2012

- Messages

- 66

There are a plethora of phases in which crystalline carbon can be ordered so you will see a variety of data published on values such as thermal conductivity. But as I mentioned in the earlier post, I have studied this in depth and have noted first hand these variations so you can really support either argument with "literature values." Furthermore, as I have learned in my years of research, much of the data that is published is crapola. You can make carbon fibers that conduct heat very well. I was well funded for a while by the DoE to investigate thermally enhanced materials and I have done the measurements myself--some carbon fibers did very, very well. Some did not.

I cannot speak first-hand on any barrel maker in this field other than Proof but the barrel I bought is great. There are down sides. The price is a huge down side. But the lag time is the worst. Right now they are running over a year on custom orders yet they will lead you into the deal promising 12-16 weeks. That's why I asked Dave about his experience with barrel life. He runs the barrel burning wild cats and if he has had prolonged barrel life out of the Proof barrels, then they may be worth it if the decrease in weight is not sufficiently beneficial.

I cannot speak first-hand on any barrel maker in this field other than Proof but the barrel I bought is great. There are down sides. The price is a huge down side. But the lag time is the worst. Right now they are running over a year on custom orders yet they will lead you into the deal promising 12-16 weeks. That's why I asked Dave about his experience with barrel life. He runs the barrel burning wild cats and if he has had prolonged barrel life out of the Proof barrels, then they may be worth it if the decrease in weight is not sufficiently beneficial.