MOA or bust

Well-Known Member

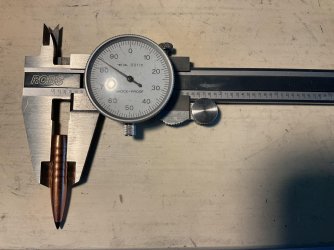

Can't figure out why bullets are loose in case when there should be adequate neck tension.

28 Nosler, Peterson brass twice fired. After sizing OD neck is 0.310. Charged case and loaded HHT 170 bullets and OD neck is .318 or so. Should be lots of neck tension but after seating the bullets, I note that I can push and pull the bullets a few one hundredths in the case, like they're moving from one bullet ridge to the next. I've loaded these before and not sure what's different now or what to do next. Help!

28 Nosler, Peterson brass twice fired. After sizing OD neck is 0.310. Charged case and loaded HHT 170 bullets and OD neck is .318 or so. Should be lots of neck tension but after seating the bullets, I note that I can push and pull the bullets a few one hundredths in the case, like they're moving from one bullet ridge to the next. I've loaded these before and not sure what's different now or what to do next. Help!