Barrel life is tied strongly to heat added to the surface of a bore/groove. The heat erodes the metal surfaces and opens every flaw -that carbon can impinge itself into.

Any cartridge can be fired at a rate that does tremendous damage to a bore, as the heat added can be too fast for flaws to close between shots. Even a smooth bore can be destroyed by this heat.

Accurate barrel life departs via two modes:

1. Carbon constriction. The ultimate killer of a barrel. Any constriction short of the muzzle kills accuracy potential.

2. Throat erosion. This affects those who need to chase lands to obtain a needed higher starting pressure. These barrels can be set back for another ~1/2 renewal in life, halving again and again, until carbon constriction takes it out for good.

Heat added follows time, and temp of powder burn per area. Heat removed follows the same between additions.

Time and area of burn typically follows powder amount per bore area (not always so simple).

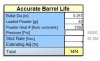

I haven't defined 'overbore', there are many definitions out there, but I consider any cartridge causing accurate barrel loss below 1500 shots, with normal use, to satisfy that aspect of overbore.

There are other attributes of over bore cartridges that are beneficial, so folks go that way regardless of barrel life. Sometimes it makes sense,, other times it's ridiculous. 264wm is an example of ridiculous. Accurate barrel life is short with it even without group shooting. A 6.5x284 is over bore, producing a competitive barrel life of ~1200 shots. A 260AI is perfect(right at the line), providing ~1900, which is likely the same as a much smaller 6.5x47L.

Under bore cartridges can also be used to great detriment of accurate barrel life. A competitive 6PPC stands as such for only ~900 shots, even burning the coolest of powder available(N133). This is a truly tiny cartridge. The biggest contributors here: Pressure(causing heat) and shot rate.

There is a new category of LR wildcats, like a 6.5saum, that rely on cool powders(like H1000) to stay afloat. Otherwise, they would not last long enough to compete.

Moly adjusts barrel life (if constantly cleaned well), through cooling of the burn via latent heat of evaporation. But if not managed correctly, moly will quickly kill a barrel's potential.

The most promising for barrel life is nitride treatment. We're talking doubling, or tripling of barrel life. But who really knows? Nobody I've read has burned a treated one out yet (no trends).