55.5grs of VV N565 pushes a 153.5 gr Berger at 3,000FPSD out of my rifle Fed 210 LRP and Lupua brassSounds great - any data?

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 PRC Powder Charge/Velocity Ladder Test. No Flat Spot

- Thread starter gregmark24

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

This is your answer. Contrary to what a lot of people in this thread have said, nodes do exist and are repeatable when found, in my experience. But I usually to .2 to .3 increments and have never found one with .5 or bigger. 0.5 increments are to find pressure.I'm no expert but my thoughts are that your flat nodes will show better with a .2 - .3 gr change in powder charge. Use the info gained above and perform another ladder to define the results.

Haven't been reloading nearly as long as a lot of guys here, so take my two cents for what they are.

BrentM

Well-Known Member

That's generally correct. Satterlee suggested it for a base, to find max, and to ident a next step starting point. Where the .5 node issue comes is we hope to find a wide node but it like 25-35 fps in .5 grains. A .3 wide node will be around 15 fps. That covers variations in the combined ammo components etc. In that area the idea is you have a fairly forgiving area to work in that should produce low sd and expected accuracy. Regardless of the may sayers, it works very well to get a person dialed in on a load in quick fashion.This is your answer. Contrary to what a lot of people in this thread have said, nodes do exist and are repeatable when found, in my experience. But I usually to .2 to .3 increments and have never found one with .5 or bigger. 0.5 increments are to find pressure.

Haven't been reloading nearly as long as a lot of guys here, so take my two cents for what they are.

Hugnot

Well-Known Member

Here are some tools that I use to make ammo:

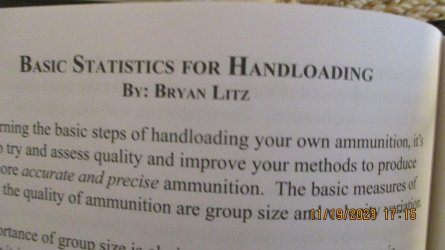

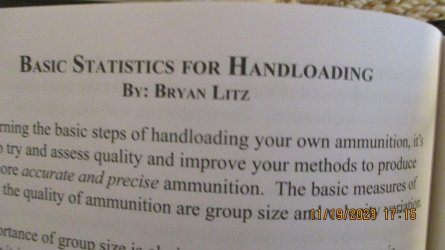

An easy to understand read by an established expert. Note "velocity variations"

Open-Office provides the way to do it.

After finding the nice accuracy node(s).

Then:

This develops the normal distribution stuff to predict average hi and lo velocities - Open Office on board software for free, like no charge.

An easy to understand read by an established expert. Note "velocity variations"

Open-Office provides the way to do it.

After finding the nice accuracy node(s).

Then:

This develops the normal distribution stuff to predict average hi and lo velocities - Open Office on board software for free, like no charge.

Last edited:

Couple comments

1. I will take Hornady results with a grain of salt. They are shooting factory ammo for their results. We have seen wild MV variances with their factory ammo. Gee no wonder they see variances.

2. I have used the ladder AND velocity node development for years. It is quick, proven and in my experience repeatable. I have taken a new barrel, broken it in, shot ladders over chrono and tweaked load and seating depth in 3 days and won state championship that weekend. total rounds fired was less than 100. I look for 2-3 rds with same basic point of impact at 300-400 yards AND similar MV nodes shooting .2-.3 grain increments. The combo of the two work. Now you can talk statistical variance reliability all you want, but no wants to burn out a barrel shooting 10-15 35 shot groups to find a starting powder load and then repeat with seating depth and burn half a barrel out.

1. I will take Hornady results with a grain of salt. They are shooting factory ammo for their results. We have seen wild MV variances with their factory ammo. Gee no wonder they see variances.

2. I have used the ladder AND velocity node development for years. It is quick, proven and in my experience repeatable. I have taken a new barrel, broken it in, shot ladders over chrono and tweaked load and seating depth in 3 days and won state championship that weekend. total rounds fired was less than 100. I look for 2-3 rds with same basic point of impact at 300-400 yards AND similar MV nodes shooting .2-.3 grain increments. The combo of the two work. Now you can talk statistical variance reliability all you want, but no wants to burn out a barrel shooting 10-15 35 shot groups to find a starting powder load and then repeat with seating depth and burn half a barrel out.

Thank YOU!Couple comments

1. I will take Hornady results with a grain of salt. They are shooting factory ammo for their results. We have seen wild MV variances with their factory ammo. Gee no wonder they see variances.

2. I have used the ladder AND velocity node development for years. It is quick, proven and in my experience repeatable. I have taken a new barrel, broken it in, shot ladders over chrono and tweaked load and seating depth in 3 days and won state championship that weekend. total rounds fired was less than 100. I look for 2-3 rds with same basic point of impact at 300-400 yards AND similar MV nodes shooting .2-.3 grain increments. The combo of the two work. Now you can talk statistical variance reliability all you want, but no wants to burn out a barrel shooting 10-15 35 shot groups to find a starting powder load and then repeat with seating depth and burn half a barrel out.

Hugnot

Well-Known Member

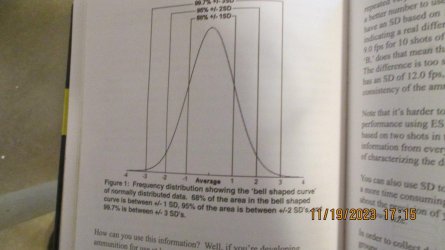

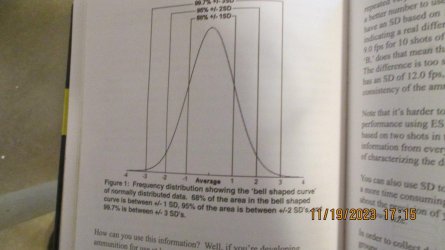

Statistics are not welcome, but the normal distribution is not an affront to ladder testing. No need to shoot 350 - 525 rounds (lots of $ & eats up barrels) to predict exceptions to vast majority of bullet velocities. The "Student T" guy figured this stuff out to predict exceptions - tails on both ends of bell-shaped curve.

Last edited:

Leaf Litter

Well-Known Member

Let's see your data supporting the existence of nodes.This is your answer. Contrary to what a lot of people in this thread have said, nodes do exist and are repeatable when found, in my experience. But I usually to .2 to .3 increments and have never found one with .5 or bigger. 0.5 increments are to find pressure.

Haven't been reloading nearly as long as a lot of guys here, so take my two cents for what they are.

For me I gave my data above. It worked and was certainly reliable and repeatable enough to win!

Year after year same results with same loads is all the evidence I need.

I'm not selling products or attempting to start fads, publish books etc.

If it didn't work I would be attempting plan B, rest assured.

I'm not selling products or attempting to start fads, publish books etc.

If it didn't work I would be attempting plan B, rest assured.

As I said, it was "in my experience," which is worth about two cents. Also, I don't do statistical studies for angry internet guys just trying to justify their own decision not to take a step in load development.Let's see your data supporting the existence of nodes.

I search for nodes, and to date, have not had the velocity spikes in temp sensitive powders that others report, and my SD/ES are much lower now than before I started searching for nodes in my load development. That's all the data I've got for you.

lancetkenyon

Well-Known Member

Therein lies your problem...Hornady....I haven't been able to find 500 or 1000 count for Hornady (yet).

Opa-lopa

Well-Known Member

Gaussian distribution is for large sample sizes, T distribution for n<30. Instead of using Extreme Spread, get targeting software & use average of Horizontal & Vertical std deviation.Pricy bullets, powder, brass, & scarce LR primers encourage smart load development.

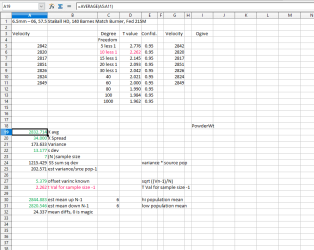

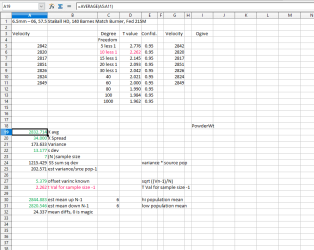

I use the "Students T" method, being unknowledgeable about the Gaussian distribution like:

View attachment 511551

This workup gives some idea of what to expect when more ammo is made using a 95% confidence level.

I select components that provide minimum extreme spreads taking into consideration other factors such as case capacity, neck tension & bullet seating depth. A sample size of 8 or more might give some indication. Shoot another batch with same values. Don't let round cook in warm/hot chamber, after shot # 6, I paused for a cool down.

Then upon selection shoot a 5 shot group at 100, after 1 fouling round. If good, shoot some more 5 shot groups at 200 & 300.

I might get a Lab Radar. That bayonet thingy looks cool but affects groups.

Never worked with the Gaussian distribution stuff but sort of think it would be similar as "bell shaped" curve or normal distribution would also be applied. The Gaussian approach might require fewer pricy components to be used up, would tails on both ends be shorter?

My first thought is that 0.6 grains interval is too large, hence the possibility to miss the "flat(ter)" portion of the curve. I used 0.2gr intervals for both Hornady ELD-X 143 and Berger EOL 156, and eventually found a couple "flatter" portions each to choose from. The rifles were 2 Tikka T3x CTR, they had practically identical chambers (quite a statement for manufacturing quality control).My buddy and I have been working together on load development for our rifles; his is a 6.5 PRC. In load testing I found a velocity flat spot with my 243, also with good POI, but he has not.

Twice now with once-fired Lapua, his powder charged different loads have tracked Gordons Reloading Tool almost exactly. No nodes. The first ladder was 0.010 off the lands with a IMR7828SSC. The second, ladder was with H4831SC, and 0.070 off the lands. He's using Fed 215M primers, producing ~50 ft/sec higher velocities than non-magnum primers (which GRT predicted), and 147 gr ELDM's. At test range of 100 yds, he produced the lowest vertical dispersions with loads 2, 5, and 7 (see chart below); and corresponding velocity SD's of 12.0, 8.9, and 4.6.

Questions:

With 0.6 gr between loads, why were there no discernible velocity flat spots, see graph - average velocities linear with powder charge increments?

He's got a carbon barrel--does the carbon damp out the harmonics/resonance of the barrel? We'd appreciate any advice you can lend.

Velocity Curve vs H4831SC w/ GM215M primers

View attachment 511077

Vertical dispersion - ignore Load 1 and load 10

View attachment 511078