j3564wost

Well-Known Member

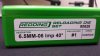

So I have finally got around to reloading some rounds for my 6.5-06ai that I purchased on here around a year ago. The rifle came with 100 rnds, so I order a set of redding FL 40 degree dies to reload once the rnds were gone. Well that time has come.....

I had a few rnds left so I based coal off of them. I ran the shells through the FL die and loaded them with 59 grns of retumbo and a 140 Berger. I'm using 280ai brass by the way.

I went the the range today to try out the new reloads and it was almost impossible to close the bolt! I was single loading them by hand and they entered the chamber just fine. But I had to push forward hard on the bolt hand and push VERY hard to close. I tried to eject some of the unfired shells that I couldn't get the bolt hand to close on and it was VERY difficult to do.

The rounds I did get the bolt closed on shot excellent .25-.5 moa just like the rounds that came with the rifle.

The only thing I can think of is that the chamber is not a 40 degree chamber???

Thanks in advance for any advice, kinda takes the fun out of shooting...

I had a few rnds left so I based coal off of them. I ran the shells through the FL die and loaded them with 59 grns of retumbo and a 140 Berger. I'm using 280ai brass by the way.

I went the the range today to try out the new reloads and it was almost impossible to close the bolt! I was single loading them by hand and they entered the chamber just fine. But I had to push forward hard on the bolt hand and push VERY hard to close. I tried to eject some of the unfired shells that I couldn't get the bolt hand to close on and it was VERY difficult to do.

The rounds I did get the bolt closed on shot excellent .25-.5 moa just like the rounds that came with the rifle.

The only thing I can think of is that the chamber is not a 40 degree chamber???

Thanks in advance for any advice, kinda takes the fun out of shooting...