You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

33 Nosler with 225 Barnes TTSX

- Thread starter Keoni7mm

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

LongBomber

Well-Known Member

I was running mine with 7977, but just swapped over to 7828sc this summer. In nosler brass I was having to keep it down around 2840fps before I would see primer pockets opening up in 2-3 loads. Swapping to Peterson brass I can push up to 3000ish before its showing any pressure. 82 gr of 7977 or 80gr of 7828sc were my max loads, my rifle lined up fairly close to hodgdon's data for max loads with a 225gr.

fseaman

Well-Known Member

I so wish I could help with more authority but my experience is with 338-26 Nosler. I have 5gn more capacity so take everything I share with 5 grains of salt

I "created" the 338-26 Nosler in 2015, the 33 Nosler was released in 2017. Nothing big, I was just not willing to wait and my 338 WinMag wasn't cutting it. I could rechamber the 338 WinMag.

Always use caution with anything suggested outside of book recommendation. Since I don't think I will be outside book...

I will echo that RL-19 and 7828ssc work in a predictable fashion. I did some work with RL-17used that in my hunting load. 7977 was too new back then. I finished my rifle, worked up my load, completed my 2015 hunt before 7977 had shipped.

A thing to look at is bullet length of the comparable bullet in copper jacket to the Barnes. The copper jacketed will be shorter. The above reference shows a BT and a Spitzer in 225. Compare them to the Barnes TTSX 225 length. If you seat the Barnes to the same COAL as say the Nosler Accubond BT, you will lose effective capacity. If you seat the Barnes to the same depth (amount of bullet in the case) then the amount of capacity is the same and the amount of powder to use should be the same. Clear as mud?

The standard mantra, start low is valid here. If you lose case capacity because of the longer Barnes bullet, look at reducing the "low" to match.

The cartridge is predictable. I started with the load data for the 338 RUM and scaled it directly for lower case capacity and accounting for bullet seating depth. There's an app for that .

.

I did use a pressure transducer.

Last note: I chose to throw TTSX 185s over RL-17 in the high 3200s range. It was great on elk. My COAL was 3.4 with a seating depth in the case of .413. This was to make my max box length and smooth seating.

I "created" the 338-26 Nosler in 2015, the 33 Nosler was released in 2017. Nothing big, I was just not willing to wait and my 338 WinMag wasn't cutting it. I could rechamber the 338 WinMag.

Always use caution with anything suggested outside of book recommendation. Since I don't think I will be outside book...

I will echo that RL-19 and 7828ssc work in a predictable fashion. I did some work with RL-17used that in my hunting load. 7977 was too new back then. I finished my rifle, worked up my load, completed my 2015 hunt before 7977 had shipped.

A thing to look at is bullet length of the comparable bullet in copper jacket to the Barnes. The copper jacketed will be shorter. The above reference shows a BT and a Spitzer in 225. Compare them to the Barnes TTSX 225 length. If you seat the Barnes to the same COAL as say the Nosler Accubond BT, you will lose effective capacity. If you seat the Barnes to the same depth (amount of bullet in the case) then the amount of capacity is the same and the amount of powder to use should be the same. Clear as mud?

The standard mantra, start low is valid here. If you lose case capacity because of the longer Barnes bullet, look at reducing the "low" to match.

The cartridge is predictable. I started with the load data for the 338 RUM and scaled it directly for lower case capacity and accounting for bullet seating depth. There's an app for that

I did use a pressure transducer.

Last note: I chose to throw TTSX 185s over RL-17 in the high 3200s range. It was great on elk. My COAL was 3.4 with a seating depth in the case of .413. This was to make my max box length and smooth seating.

Thanks. not much information on this round for Barnes but much appreciated. I knew someone had something about it.I so wish I could help with more authority but my experience is with 338-26 Nosler. I have 5gn more capacity so take everything I share with 5 grains of salt

I "created" the 338-26 Nosler in 2015, the 33 Nosler was released in 2017. Nothing big, I was just not willing to wait and my 338 WinMag wasn't cutting it. I could rechamber the 338 WinMag.

Always use caution with anything suggested outside of book recommendation. Since I don't think I will be outside book...

I will echo that RL-19 and 7828ssc work in a predictable fashion. I did some work with RL-17used that in my hunting load. 7977 was too new back then. I finished my rifle, worked up my load, completed my 2015 hunt before 7977 had shipped.

A thing to look at is bullet length of the comparable bullet in copper jacket to the Barnes. The copper jacketed will be shorter. The above reference shows a BT and a Spitzer in 225. Compare them to the Barnes TTSX 225 length. If you seat the Barnes to the same COAL as say the Nosler Accubond BT, you will lose effective capacity. If you seat the Barnes to the same depth (amount of bullet in the case) then the amount of capacity is the same and the amount of powder to use should be the same. Clear as mud?

The standard mantra, start low is valid here. If you lose case capacity because of the longer Barnes bullet, look at reducing the "low" to match.

The cartridge is predictable. I started with the load data for the 338 RUM and scaled it directly for lower case capacity and accounting for bullet seating depth. There's an app for that.

I did use a pressure transducer.

Last note: I chose to throw TTSX 185s over RL-17 in the high 3200s range. It was great on elk. My COAL was 3.4 with a seating depth in the case of .413. This was to make my max box length and smooth seating.

sounds like a start for me. thank you!I was running mine with 7977, but just swapped over to 7828sc this summer. In nosler brass I was having to keep it down around 2840fps before I would see primer pockets opening up in 2-3 loads. Swapping to Peterson brass I can push up to 3000ish before its showing any pressure. 82 gr of 7977 or 80gr of 7828sc were my max loads, my rifle lined up fairly close to hodgdon's data for max loads with a 225gr.

fseaman

Well-Known Member

I wish I could tell you a charge and COAL but instead, how to start from comparable data is the best I can do.Thanks. not much information on this round for Barnes but much appreciated. I knew someone had something about it.

Do you know the COAL you want to use? If you do, I can try to help narrow the load down with you.

to be honest, I don't know where to start? I just don't want to waste any time and possibly F it up. i'm thinking 3.290" C.O.A.L??I wish I could tell you a charge and COAL but instead, how to start from comparable data is the best I can do.

Do you know the COAL you want to use? If you do, I can try to help narrow the load down with you.

memtb

Well-Known Member

Keoni7mm,

I'm meddling in your business, but have you already purchased your 225 TTSX's?

If not, and you are planning on using this for long range (greater than 500 yards), if so, have you considered the 250 grain LRX?

I crunched some numbers using it in a .338WM……which I think that your 33 Nosler across most powders can exceed in most loadings.

I believe that for long range use……the 250 LRX will catch and pass the 225 in terms of trajectory, drift, and energy (if ft/lbs energy is your thing). The 250 should give slightly better penetration throughout it's distance usage. And they are designed to expand at lower velocities than the TTSX's……another small plus! memtb

There won't be big differences…..merely slight differences at extended ranges. memtb

I'm meddling in your business, but have you already purchased your 225 TTSX's?

If not, and you are planning on using this for long range (greater than 500 yards), if so, have you considered the 250 grain LRX?

I crunched some numbers using it in a .338WM……which I think that your 33 Nosler across most powders can exceed in most loadings.

I believe that for long range use……the 250 LRX will catch and pass the 225 in terms of trajectory, drift, and energy (if ft/lbs energy is your thing). The 250 should give slightly better penetration throughout it's distance usage. And they are designed to expand at lower velocities than the TTSX's……another small plus! memtb

There won't be big differences…..merely slight differences at extended ranges. memtb

Last edited:

fseaman

Well-Known Member

Your COAL is book length. That makes things easier to compare.to be honest, I don't know where to start? I just don't want to waste any time and possibly F it up. i'm thinking 3.290" C.O.A.L??

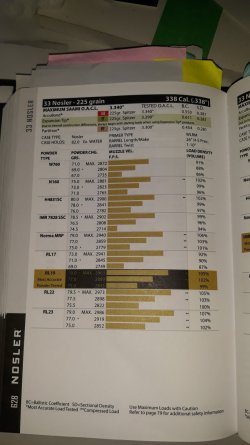

Looking at the data above and comparing the Barnes 225 TTSX 1.550" to the Nosler Expansion Tip lead free 1.575". The Barnes is 0.025 shorter. So...

When seated to the same COAL there would be a tiny bit more effective case capacity. Unfortunate my "there's an app for that" is on a computer that is now dead. Waiting for new discs.

However, to me this indicates that the load data for the Nosler Expansion Tip is very comparable to what I would use for the TTSX.

I can't tell you an actual COAL or charge but look at the above sheet, think about that there is only a fraction more case capacity an decide if you are comfortable with using that COAL and charge range from the Nosler manual.

I can tell you that it fits the ranges used in my 338-26 Nosler after adjusting for lower case capacity.

I hope that helps get you started.

fseaman

Well-Known Member

This is valid.Keoni7mm,

I'm meddling in your business, but have you already purchased your 225 TTSX's?

If not, and you are planning on using this for long range (greater than 500 yards), if so, have you considered the 250 grain LRX?

I crunched some numbers using it in a .338WM……which I think that your 33 Nosler across most powders can exceed in most loadings.

I believe that for long range use……the 250 LRX will catch and pass the 225 in terms of trajectory, drift, and energy (if ft/lbs energy is your thing). The 250 should give slightly better penetration throughout it's distance usage. And they are designed to expand at lower velocities than the TTSX's……another small plus! memtb

There won't be big differences…..merely slight differences at extended ranges. memtb

33 Nosler Load Data

Explore the world of Nosler, renowned for crafting the finest bullets, ammunition, rifles, and brass. Discover our extensive lineup, including Partition, AccuBond, E-Tip, Ballistic Tip, Custom Competition, and more. Experience superior quality and performance with Nosler products.

The Barnes 250 LRX is supposed to be 1.713" and the Nosler E-Tip 1.680" so at the same COAL per book 3.25, the Barnes would have a little less effective capacity. Just reverse the previous.

Here is another way to think about it. If you seat the Barnes to 3.290 then the effective volume is virtually the same.

Do you have an OAL tool?

Lock‑N‑Load® O.A.L. Gauges & Modified Cases - Hornady Manufacturing, Inc

Lock-N-Load® O.A.L. Gauges Regulating seating depth and the resulting jump to the rifling is widely regarded as fundamental to improved accuracy. A few thousandths of an inch change between the bullet and the rifling can make the difference betw...

memtb

Well-Known Member

This is valid.

33 Nosler Load Data

Explore the world of Nosler, renowned for crafting the finest bullets, ammunition, rifles, and brass. Discover our extensive lineup, including Partition, AccuBond, E-Tip, Ballistic Tip, Custom Competition, and more. Experience superior quality and performance with Nosler products.www.nosler.com

The Barnes 250 LRX is supposed to be 1.713" and the Nosler E-Tip 1.680" so at the same COAL per book 3.25, the Barnes would have a little less effective capacity. Just reverse the previous.

Here is another way to think about it. If you seat the Barnes to 3.290 then the effective volume is virtually the same.

Do you have an OAL tool?

Lock‑N‑Load® O.A.L. Gauges & Modified Cases - Hornady Manufacturing, Inc

Lock-N-Load® O.A.L. Gauges Regulating seating depth and the resulting jump to the rifling is widely regarded as fundamental to improved accuracy. A few thousandths of an inch change between the bullet and the rifling can make the difference betw...www.hornady.com

Kinda along these lines.

Are you set on 3.290" as your OAL…..is it because of magazine length?

Generally, Barnes' like a lot of "jump"…..which is beneficial in staying within magazine length restrictions.

While many shun the practice……I have no issues with compressed loads. So the length of the heavier bullet may be a "non-issue" if you compress!

While I'm certainly not recommending this practice…..I once used a powder (RL 19) while I was experiencing my own private powder shortage, that was far too slow for the intended application. Using an 8" drop tube, while very lightly tapping the case sides, I was able to get the charge into the case……about 1/16" below the case rim. THEN……proceeded to seat a 270 grain TSX onto the case.

I immediately discovered that, you could not rapidly seat the bullet in one handle stroke……the case bulged near the shoulder. So, I very slowly seated the bullet……success!

They were accurate, and met my velocity desires. I followed this procedure until I was able to obtain a much more desirable powder for the application. Still a compressed load……but, far less compression! memtb

MagnumManiac

Well-Known Member

My best procedure loading Barnes bullets has always been starting .050" off the lands and INCREASING jump to tune.

Not once has this failed.

However, I will say, I load to max mag length in Weatherby's, this too has always worked.

Cheers.

Not once has this failed.

However, I will say, I load to max mag length in Weatherby's, this too has always worked.

Cheers.