Gentlemen, I have just finished wrestling with the same symtoms with my 338/408. Even with very mild loads the cases get progressively tighter with each firing. I FL sized between each firing, the shoulder was bumped and was not the problen. As it turned out my chamber is just a smidge tighter than my FL die just above the case head. Part of the case is not being resized at all and is simply getting tighter with each firing. This seems to be a fairly rare occurance, I have never seen this happen before. I did a little research and the cases with the least amount of taper are more inclined to have the affliction. I have a 375/408 die that cures the problem but accuracy goes to pot. This may or may not be the cause in jons case but it certianly could be. Changing factory dies probably wont help because it is probable the chamber is a little tight. I pulled my barrel and polished the chamber which helped somewhat. I am trying to decide to polish more or try to get a set of dies that will work.

-

If you are being asked to change your password, and unsure how to do it, follow these instructions. Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

300RUM reloading experts needed

- Thread starter 308 nate

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Gents,

I have two 300 RUM Remington Factory Rifles. I am getting close to using

up about 12 lbs of Retumbo of about 3 or four different Lot Numbers. I have

Nothing but a lot of respect and good things to say about Hodgdon Retumbo

Powder. In the Cold and in Hot temps; on my first load or my fifth load...

The problem that's taking place here is very interesting but I don't see the

Retumbo Powder having anything to do with it. Bullets? They change in diame-

ter as well as in hardness and that easily could change the amount of the

charge. That's just normal. Your solution, IMHO, is something else. Check your

powder measuring scales and make sure that not air drafts are moving through the room

while reloading.

I have two 300 RUM Remington Factory Rifles. I am getting close to using

up about 12 lbs of Retumbo of about 3 or four different Lot Numbers. I have

Nothing but a lot of respect and good things to say about Hodgdon Retumbo

Powder. In the Cold and in Hot temps; on my first load or my fifth load...

The problem that's taking place here is very interesting but I don't see the

Retumbo Powder having anything to do with it. Bullets? They change in diame-

ter as well as in hardness and that easily could change the amount of the

charge. That's just normal. Your solution, IMHO, is something else. Check your

powder measuring scales and make sure that not air drafts are moving through the room

while reloading.

Varmint Hunter

Well-Known Member

Gentlemen, I have just finished wrestling with the same symtoms with my 338/408. Even with very mild loads the cases get progressively tighter with each firing. I FL sized between each firing, the shoulder was bumped and was not the problen. As it turned out my chamber is just a smidge tighter than my FL die just above the case head. Part of the case is not being resized at all and is simply getting tighter with each firing. This seems to be a fairly rare occurance, I have never seen this happen before. I did a little research and the cases with the least amount of taper are more inclined to have the affliction. I have a 375/408 die that cures the problem but accuracy goes to pot. This may or may not be the cause in jons case but it certianly could be. Changing factory dies probably wont help because it is probable the chamber is a little tight. I pulled my barrel and polished the chamber which helped somewhat. I am trying to decide to polish more or try to get a set of dies that will work.

Augustus - you may be on to something. I emailed a copy of my reamer specs to Redding and then called them. They suspected that the chamber was a bit too tight for their standard dies and offered to make a set of custom dies from a few fired cases. The price was very high. They also suggested that I may want to polish out the chamber a bit. However, my smith along with one of the board regular smiths highly recommended against doing this because you "run the risk of ruining a precision cut chamber". Rechambering to a standard (non-minimum spec) chamber was suggested by one of them.

I opted to try the Forester FL die which appeared to be a bit tighter but to no avail.

I'm taking the rifle to North Carolina in 10 days for some deer hunting. For now, I just loaded up some new brass with my accuracy load and will work on this problem when I get back. The new brass always extracts smoothly. Hmmmmmmm????

tjonh2001

Well-Known Member

guys i have changed powder and i have even used a different scale. i am thinking that i might have a tighter chamber and the dies arent resizeing them all the way i have tried redding and rcbs dies. the one thing is that we did polish the chamber one more time and it has made it better but not fix the problem and i am worried that if we polish more might oval the chamber and that would be a shame.

J E Custom

Well-Known Member

Augustus - you may be on to something. I emailed a copy of my reamer specs to Redding and then called them. They suspected that the chamber was a bit too tight for their standard dies and offered to make a set of custom dies from a few fired cases. The price was very high. They also suggested that I may want to polish out the chamber a bit. However, my smith along with one of the board regular smiths highly recommended against doing this because you "run the risk of ruining a precision cut chamber". Rechambering to a standard (non-minimum spec) chamber was suggested by one of them.

I opted to try the Forester FL die which appeared to be a bit tighter but to no avail.

I'm taking the rifle to North Carolina in 10 days for some deer hunting. For now, I just loaded up some new brass with my accuracy load and will work on this problem when I get back. The new brass always extracts smoothly. Hmmmmmmm????

I would vote for the rechambering Instead of polishing because polishing is not exact and you

run the risk of ruining the chamber.

This is a very good post for all to learn and it will be interesting to find out exactly what the problem is.

I believe in treating the problem not the symptoms and the chamber sounds like the problem

at this time.

J E CUSTOM

Dano1

Well-Known Member

Guys,

I just had a thought run though my head while reading this thread. Another possible problem may be powder residue buildup in the case, decreasing the case volume and there by increasing the pressures with the same powder charge.

Not saying that this is the problem, just a thought that hadn't been brought up. Retumbo is a fairly clean burning powder, but all powders will leave a buildup in the case over time. With 3 fireings is not likely, but maybe so....

I've actually seen this in .30-06 Cases and .270 cases using IMR or Reloader powders.

Without seeing the brass and mic-ing the cases, it's hard to see what the problem could be. I am seeing a little of this, with my friends .300RUM that I load for, but not nearly to this extent.

Just a thought?

Dan

I just had a thought run though my head while reading this thread. Another possible problem may be powder residue buildup in the case, decreasing the case volume and there by increasing the pressures with the same powder charge.

Not saying that this is the problem, just a thought that hadn't been brought up. Retumbo is a fairly clean burning powder, but all powders will leave a buildup in the case over time. With 3 fireings is not likely, but maybe so....

I've actually seen this in .30-06 Cases and .270 cases using IMR or Reloader powders.

Without seeing the brass and mic-ing the cases, it's hard to see what the problem could be. I am seeing a little of this, with my friends .300RUM that I load for, but not nearly to this extent.

Just a thought?

Dan

tjonh2001

Well-Known Member

Guys,

I just had a thought run though my head while reading this thread. Another possible problem may be powder residue buildup in the case, decreasing the case volume and there by increasing the pressures with the same powder charge.

Not saying that this is the problem, just a thought that hadn't been brought up. Retumbo is a fairly clean burning powder, but all powders will leave a buildup in the case over time. With 3 fireings is not likely, but maybe so....

I've actually seen this in .30-06 Cases and .270 cases using IMR or Reloader powders.

Without seeing the brass and mic-ing the cases, it's hard to see what the problem could be. I am seeing a little of this, with my friends .300RUM that I load for, but not nearly to this extent.

Just a thought?

Dan

this was one of the first things that we looked at and have concluded not to be as i have weighed a case before and after 5 firings and the only build up was some carbon.

Nate has a idea that he going to test should know more here in a couple days. cross your fingers

woods

Well-Known Member

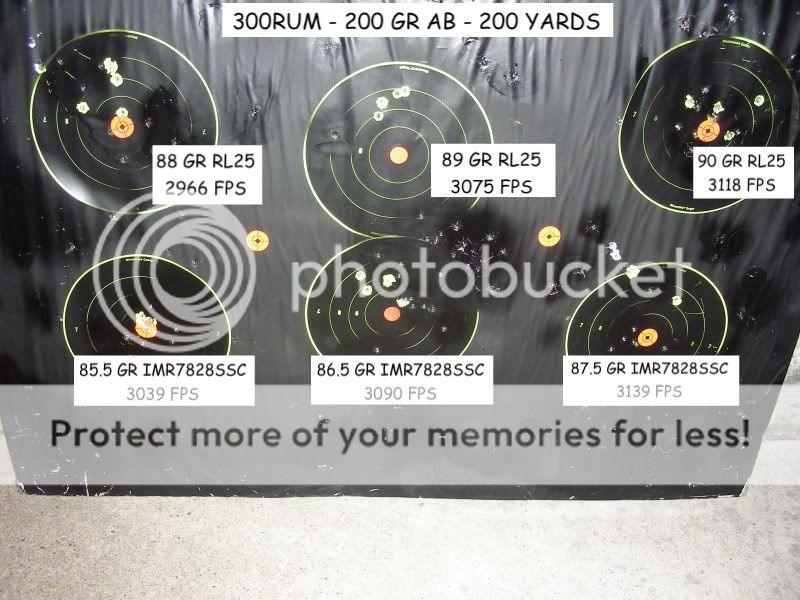

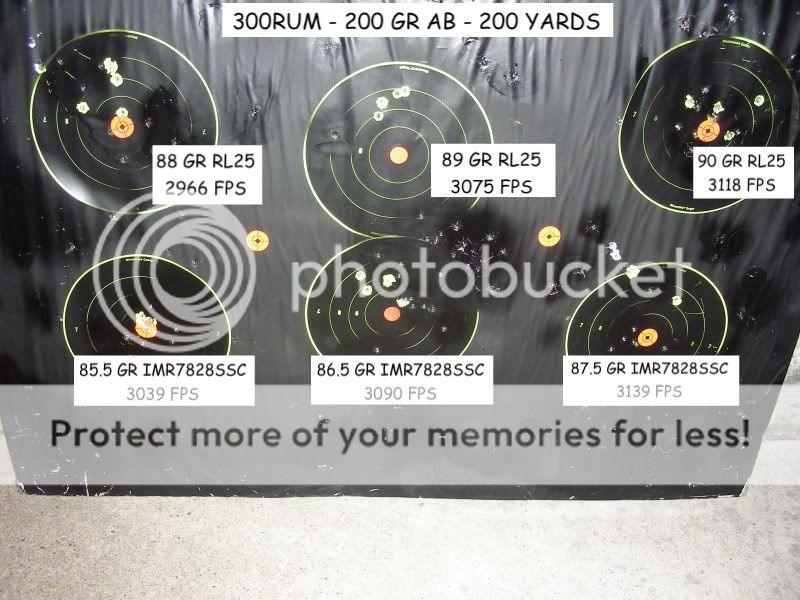

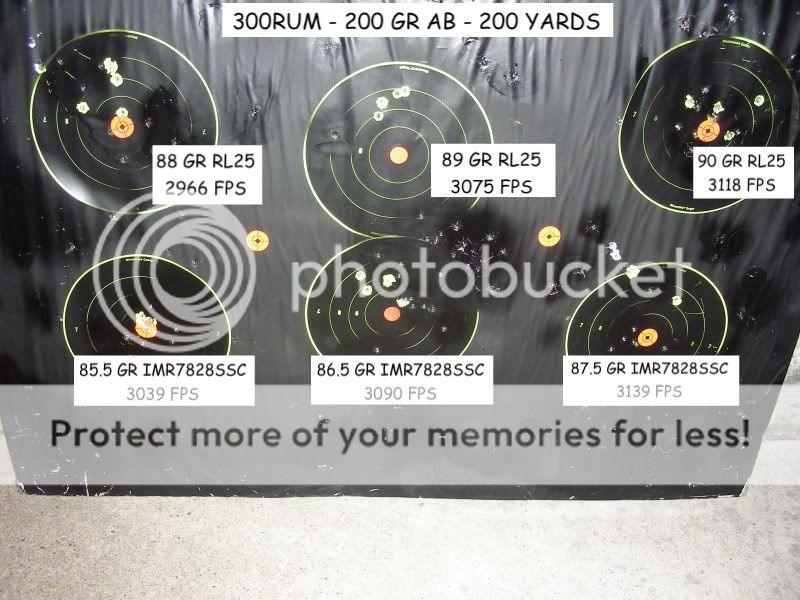

Another mysterious 300RUM experience here. This gun is a Sendero in a Choate stock

and I started with new cases using the 200 gr Accubond and RL25 and IMR7828SSC and everything seemed normal

and the lowest load of IMR7828SSC looked good

so I loaded up 50 of the once fired cases with 86 gr IMR7828SSC for his box of ammo which is 1.5 gr below max in the Nosler #5 and went to the range to verify zero. I got pressure signs on the case head

so I pulled the bullets and took out another grain of powder. Unfortunately I did not chronograph the 86 gr load.

But this has me scratching my head when I am well below max and getting pressure signs on loads that I had previously verified. The only other piece of information I have is that there is .011" neck clearance on a loaded round which seemed excessive (.346"-.335"=.011")

Somebody figure this out!

and I started with new cases using the 200 gr Accubond and RL25 and IMR7828SSC and everything seemed normal

and the lowest load of IMR7828SSC looked good

so I loaded up 50 of the once fired cases with 86 gr IMR7828SSC for his box of ammo which is 1.5 gr below max in the Nosler #5 and went to the range to verify zero. I got pressure signs on the case head

so I pulled the bullets and took out another grain of powder. Unfortunately I did not chronograph the 86 gr load.

But this has me scratching my head when I am well below max and getting pressure signs on loads that I had previously verified. The only other piece of information I have is that there is .011" neck clearance on a loaded round which seemed excessive (.346"-.335"=.011")

Somebody figure this out!

MontanaRifleman

Well-Known Member

Another mysterious 300RUM experience here. This gun is a Sendero in a Choate stock

and I started with new cases using the 200 gr Accubond and RL25 and IMR7828SSC and everything seemed normal

and the lowest load of IMR7828SSC looked good

so I loaded up 50 of the once fired cases with 86 gr IMR7828SSC for his box of ammo which is 1.5 gr below max in the Nosler #5 and went to the range to verify zero. I got pressure signs on the case head

so I pulled the bullets and took out another grain of powder. Unfortunately I did not chronograph the 86 gr load.

But this has me scratching my head when I am well below max and getting pressure signs on loads that I had previously verified. The only other piece of information I have is that there is .011" neck clearance on a loaded round which seemed excessive (.346"-.335"=.011")

Somebody figure this out!

There is an ejector mark on the brass and some cratering on the primer, but... primers aren't flattened. I see this a lot in my 300 RUM over a range of powder charges. When primers get flattened and you get a sticky bolt, that's when I figure pressure is getting up there. My number one sign to look for in pressure is way flattened primers. i have had sticky bolts in light loads for who knows what reason. When they are really stiff... that really gets my attention. Ejector marks and cratered primers can be indicators, but I am finding it depends a lot on the cartridge and the rifle.

In the LR game, it seems we try to squeeze out all we can and are working on the edge. Handloading is combination of science and black arts, especially when it come to these kind of cartridges.

Can hardly wait to see what comes out of this thread.

tjonh2001

Well-Known Member

guys i think that we might have the culperate and once the testing gets done we will let all of you know what the deal is. i have posted this post on other sites and it is mind boggling how many people have this issue in all of the big calibers. i am hoping to get my rifle to nate and try the theary. once everything is good we will let all of you know.

the only bad thing is that i have put alot of testing rounds down a $1000 barrel.

the only bad thing is that i have put alot of testing rounds down a $1000 barrel.

Varmint Hunter

Well-Known Member

The theory that powder residue or carbon is building up inside the case and reducing the case capacity which is ultimately causing excessive pressure doesn't wash, at least not for me.

In my situation the cases go from "smooth extraction" to "won't extract" in just one firing. Additionally, a radical increase in pressure usually results in a noticeable increase in muzzle velocity. I shoot all of my loads over an Oehler 35 and have never noticed an increase in pressure which coincided with the stuck cases.

In my situation the cases go from "smooth extraction" to "won't extract" in just one firing. Additionally, a radical increase in pressure usually results in a noticeable increase in muzzle velocity. I shoot all of my loads over an Oehler 35 and have never noticed an increase in pressure which coincided with the stuck cases.

tjonh2001

Well-Known Member

We should know more tonmarrow I got my rifle to nate tonight. As for what we are seeing I think its something besides pressure. Just looks like pressure. Cross your fingers guys

308 nate

Well-Known Member

I have found the problem!!lightbulb

My reamer was on the minimum allowable tolerance for a 300 ultra match reamer.

resized to fired brass was just under .002 on the body, my findings were that we need to have .003 difference from fired to resized. I took my 7 ultra mag reamer(match grade) and ran it in the 300 ultra chambered barrel. according to the prints the dimensions are identical on the body and took out approx .0015, then I loaded up a new case with 92gr. of retumbo and a 210 Berger. Velocity was 3100 FPS. I proceeded to reload and fire the case three times with 92 grains and the case just fell out every time. No extraction cam was even being used. So, I took her up to 93 grains and still no extraction problems, then I went to 93.5 grs. and again zero extraction problems, worked smooth as butter every time. It will not hold primers after 5 firings, ES was under 10FPS, accuracy was sub 1/3 moa at 600yds.

I am relieved to have found the problem, but would like to offer my apologies for letting this out of my shop. This has been a big learning experience for me. In my test firings everything was fine as I used new brass every time. Also this is not causing extra pressure in your guns as your bolt lift is still easy until it hits extraction. The body of the brass is just not pulling back off the chamber and dragging. I have determined there is no real safety issue here as velocity does not increase even when the cases are sticking, just a very large annoyance!

I would like to fix the problem on all the 300 RUM's I have out. if you are having this problem, which I suspect you are.....I am willing to pay shipping both ways

and get them back to you as soon as possible. Please contact me if you have one of my SSG built rifles and are having this problem.

For those that are having this same problem and that do not have SSG built rifles it is very likely you do not have enough clearance between your chamber and resizing die, weather it be wildcats or standard chamberings. I believe this "sticking issue" is something we will only see in the large diameter high power magnum cases. In the near future I will do my best to go through my records and contact all my customers that have bought SSG 300 RUM's and make them aware of my findings and restitution offer.

I would ask that you would be patient with me at this time as I am truly overwhelmed with the hunting season rush as well as hoping to do some hunting myself. In other words, if you e-mail and I do not get back to you right away, I am not ignoring you I just haven't been able to respond as quickly as I would have hoped.

I hope others can learn from these posts. I am truly thankful for all your replies.

You guys are awesome!

I wish you a great hunting season!!

sincerely,

Nate

My reamer was on the minimum allowable tolerance for a 300 ultra match reamer.

resized to fired brass was just under .002 on the body, my findings were that we need to have .003 difference from fired to resized. I took my 7 ultra mag reamer(match grade) and ran it in the 300 ultra chambered barrel. according to the prints the dimensions are identical on the body and took out approx .0015, then I loaded up a new case with 92gr. of retumbo and a 210 Berger. Velocity was 3100 FPS. I proceeded to reload and fire the case three times with 92 grains and the case just fell out every time. No extraction cam was even being used. So, I took her up to 93 grains and still no extraction problems, then I went to 93.5 grs. and again zero extraction problems, worked smooth as butter every time. It will not hold primers after 5 firings, ES was under 10FPS, accuracy was sub 1/3 moa at 600yds.

I am relieved to have found the problem, but would like to offer my apologies for letting this out of my shop. This has been a big learning experience for me. In my test firings everything was fine as I used new brass every time. Also this is not causing extra pressure in your guns as your bolt lift is still easy until it hits extraction. The body of the brass is just not pulling back off the chamber and dragging. I have determined there is no real safety issue here as velocity does not increase even when the cases are sticking, just a very large annoyance!

I would like to fix the problem on all the 300 RUM's I have out. if you are having this problem, which I suspect you are.....I am willing to pay shipping both ways

and get them back to you as soon as possible. Please contact me if you have one of my SSG built rifles and are having this problem.

For those that are having this same problem and that do not have SSG built rifles it is very likely you do not have enough clearance between your chamber and resizing die, weather it be wildcats or standard chamberings. I believe this "sticking issue" is something we will only see in the large diameter high power magnum cases. In the near future I will do my best to go through my records and contact all my customers that have bought SSG 300 RUM's and make them aware of my findings and restitution offer.

I would ask that you would be patient with me at this time as I am truly overwhelmed with the hunting season rush as well as hoping to do some hunting myself. In other words, if you e-mail and I do not get back to you right away, I am not ignoring you I just haven't been able to respond as quickly as I would have hoped.

I hope others can learn from these posts. I am truly thankful for all your replies.

You guys are awesome!

I wish you a great hunting season!!

sincerely,

Nate